Researchers Develop Multispectral Light Field Camera Using Inkjet Printing

Karlsruhe Institute of Technology researchers have developed a proof-of-concept multispectral 3D camera that features optical components made using an inkjet printer.

Researchers at the Karlsruhe Institute of Technology in Germany have developed a multispectral light field camera with inkjet-printed optical components. The camera is in the proof-of-concept stage but has been built and tested with its multi-lens arrangement focused on future applications in recycling processes and autonomous vehicle navigation. Palm-of-hand sized, it can take one image that provides all of the information that would require many scans of a standard camera.

The Karlsruhe Institute of Technology’s proof-of-concept light field camera with inkjet-printed optical components. Image used courtesy of Karlsruhe Institute of Technology

What Is a Light Field Camera?

A light field camera is different from a regular camera. While a regular camera captures light intensity at a select set of wavelengths of light, a light field camera captures the intensity and direction of the light as it passes through the lenses. Another way to think of this is that a light field camera captures more information about what it is photographing than a standard camera. The extra information can even be used to make three-dimensional images from a single exposure.

Light field cameras can be built with several techniques. One of the more common techniques is to place small microlenses overtop of a standard camera optic system. Each of these smaller lenses can be used to capture light at only specific angles. The light from all of these microlenses can be focused onto a camera’s main lens.

This is comparable to a fly’s eye. Flies have a compound eye that captures light repeatedly. Rather than focusing all of the light in one place, a fly sees a mosaic with many repeated images. It helps them detect motion much easier (as motion appears in each lens), but it does not produce the 3D image in the same manner as a light field camera.

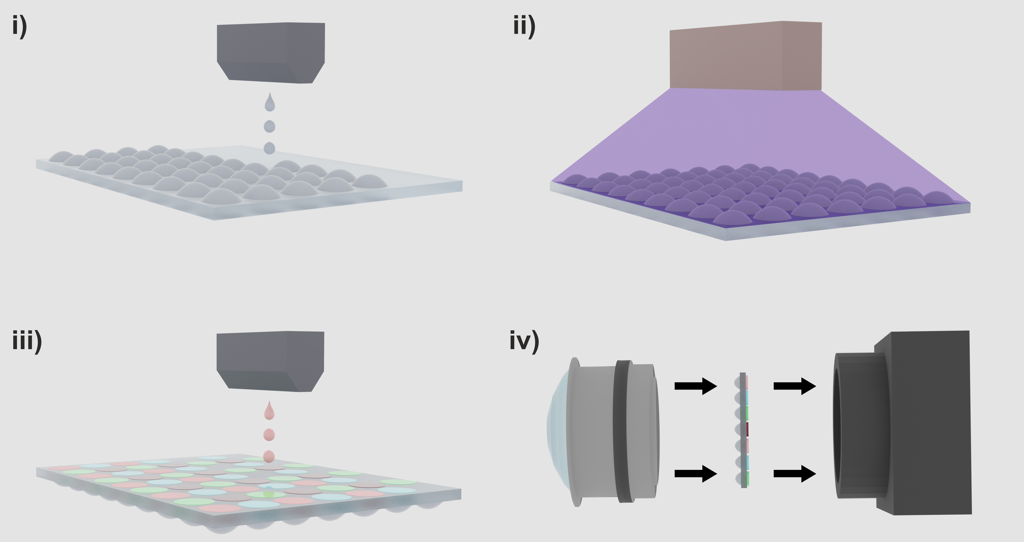

Individual lenses are inkjet printed onto a microscope slide. Once cured, color filters are inkjet printed on the opposite side of the slide. The slide is then integrated on a CMOS camera chip and built into the camera’s housing. Image used courtesy of Karlsruhe Institute of Technology

Multispectral 3D Camera From an Inkjet Printer

The Karlsruhe Institute of Technology researchers’ light field camera prototype was made with the help of inkjet printing. On one side of a glass microscope slide, the printer prints a myriad of tiny lenses. On the backside of the slide, the inkjet printer produces color filters for filtering in the incoming light. The microscope slide is then attached to a standard CMOS camera chip. The end result is a series of lenses that capture light at different angles but focus them on the lens of the CMOS chip. In one image, all of the information is present.

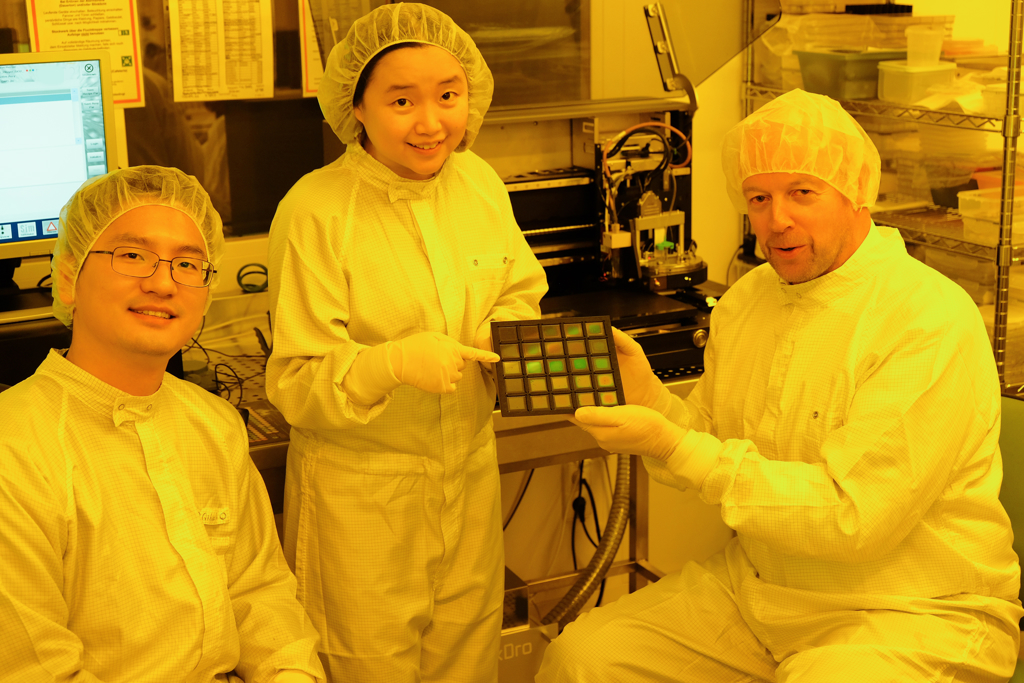

To test this prototype, the research lab created a testbed of multi-colored, three-dimensional objects. The camera was tested against this test bed, and, through software, was able to successfully identify each object.

Karlsruhe Institute of Technology researchers showcasing color filters made from inkjet printing. Image used courtesy of Karlsruhe Institute of Technology

Multispectral Light Field Camera Applications

With the ability to inkjet print optical components, light field cameras could be manufactured on a larger scale and with greater customizability. These cameras would be suitable for use in harsh environments, where standard commercial light field cameras may be too costly to replace frequently. One such application is for sorting recycled materials, where a light field camera can identify an object and a controller can move a robotic arm to select that item. Given the exposure to what amounts to trash, a commercial camera would need frequent replacements.

Another possible market for these cameras is in autonomous driving applications. Once again, the camera would be exposed to moisture, road salt, mud, and other contaminants and need frequent replacement. Furthermore, light field imaging can help identify hazards in three dimensions, aiding collision avoidance algorithms.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin