Rockwell Automation Announces a New Product, Partnership, and Expansion

Rockwell Automation has started constructing a new manufacturing facility in India, developed a low-voltage motor control center, and partnered with an educational institution to invest in the future workforce.

Global industrial automation provider Rockwell Automation continues to expand its offerings and grow its presence. The company has announced plans to build a manufacturing facility that will serve the Asia-Pacific region, launched a low-voltage motor control center, and partnered with Mahindra University to develop and inspire sustainability in manufacturing.

Rockwell is building a 98,000-square-foot manufacturing facility in Chennai, India, to strengthen its presence across the Asia-Pacific region. Image used courtesy of Rockwell Automation

Asia-Pacific Expansion

One of Rockwell's newest endeavors is the construction of a 98,000-square-foot manufacturing plant in Chennai, India. The design of this plant will allow it to be expandable to meet future business demands. With India as the fifth fastest growing economy, this plant is being built to secure supply chains around the Asia-Pacific region. Co-located with Rockwell’s existing CUBIC plant, it will provide additional opportunities for workers to find the right career fit, as well as provide new collaboration between facilities. The new plant is expected to begin operations in 2025 and will employ around 230 workers.

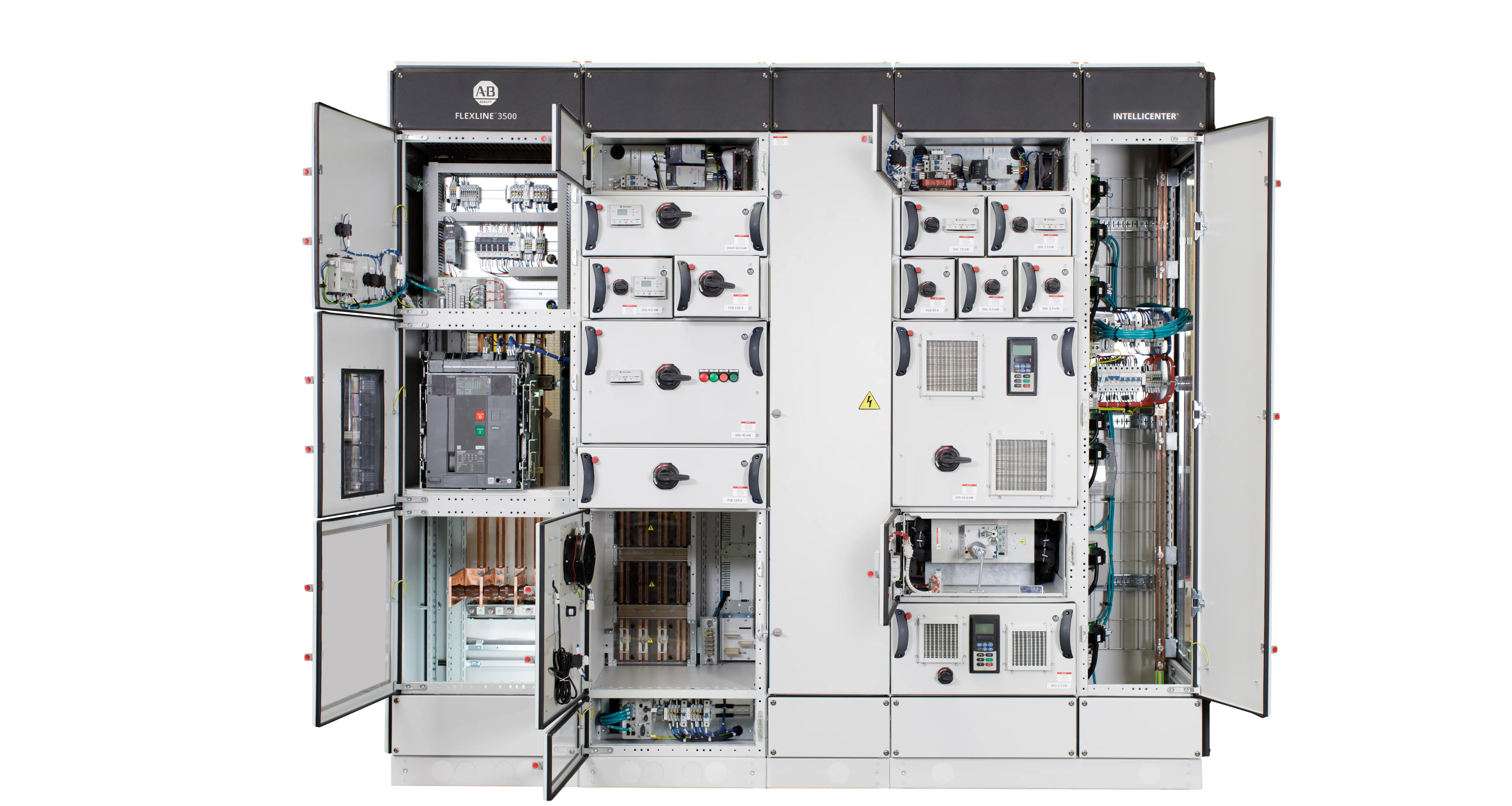

The Allen-Bradley FLEXLINE 3500 low-voltage motor control center. Image used courtesy of Rockwell Automation

FLEXLINE 3500 Motor Control Center

Rockwell has also launched the Allen-Bradley FLEXLINE 3500 low-voltage motor control center, which aims to simplify controls and reduce maintenance downtime. Smart devices placed in the FLEXLINE 3500 system can collect real-time data, save energy, improve safety across the plant, and provide other such benefits.

The key feature of this center is the ability to place motor controls, power supplies, and other equipment in the same central location, simplifying troubleshooting and maintenance tasks. Ultimately, this results in reduced downtime, less time training new maintenance technicians, simplified cabling, and fewer expenses during installation, commissioning, and operation.

Rockwell’s latest motor control center is designed to meet IEC markets, meeting IEC 61439 1&2. These two standards lay out safe and efficient designs for motor controllers and low-voltage switchgear.

Rockwell and Mahindra University have entered into an MOU to create a climate-focused curriculum targeting the future workforce. Image used courtesy of Rockwell Automation

Partnership With Mahindra University

With a focus on sustainability and education, Rockwell Automation has entered into a memorandum of understanding (MOU) with Mahindra University. In this MOU, the two organizations will work together to add a “Climate Solutions” course to the university’s curriculum. This course is set to train students on sustainable manufacturing techniques that optimize the smart use of resources and energy to tackle real-world problems.

“Our partnership with Rockwell reinforces our commitment to advancing sustainability education and is an important step towards equipping the next generation of leaders with the expertise and technical skills to address some of the greatest challenges in the world,” says Anirban Ghosh, Head of the Centre for Sustainability at Mahindra University in regard to the new development. The course will be piloted in August 2024.

Investing in the Future

Rockwell continues to innovate with new partnerships, facilities, and products. These latest round of advancements show the company’s ongoing commitment to growth, sustainability, and education in the global automation space.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin