Rockwell Automation Upsizes the iTRAK Conveyor System with Larger Units

Rockwell Automation expands the iTRAK servo conveyor catalog with models designed for high-payload applications while still including all of the features of existing units.

The new iTRAK units from Rockwell Automation optimize conveyor systems to avoid traffic jams. The new units offer greater size, extensibility, and safety features. The units provide additional options for their packaging or transport applications.

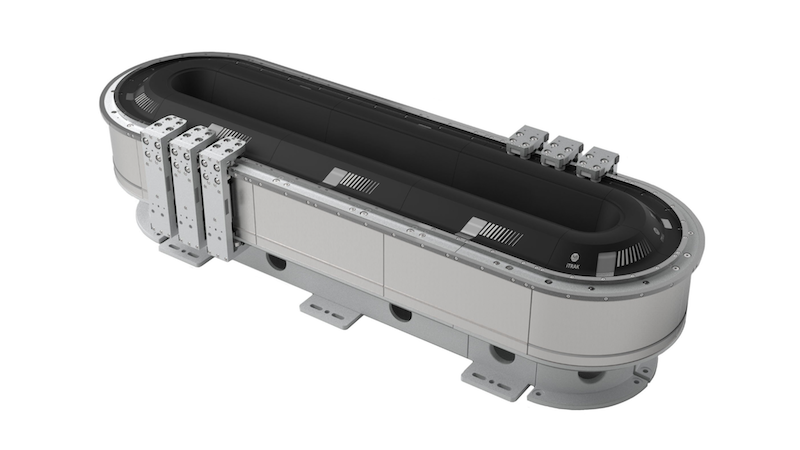

The iTRAK conveyor model from Rockwell Automation. Image used courtesy of Rockwell Automation

iTRAK Conveyance System

The iTRAK from Rockwell Automation is a conveyance system that uses linear servo motors to move and position shuttles or movers along the perimeter of a closed-loop track. These systems work well with automation systems that require precise high-speed motion between stations.

The ITRAK system comes in two versions–the small frame 5730 and the medium frame 5750. Both systems have a maximum speed of 5 meters per second and can combine up to 64 sections holding 128 shuttles to create the track.

The 5750 model offers four different shuttles ranging in size from 50mm x 50mm to 100mm x 100mm. The system is IP66-rated and includes safe torque-off functions with a SIL 3 classification. The stainless steel construction of the rail allows for a vertical, horizontal, or 90-degree mounting configuration.

Both systems use the gigabit Ethernet infrastructure that supports EtherNET/IP industrial communication. Additionally, both have anti-collision functions built-in. Rockwell’s Application Code Manager and machine builder libraries can be used to develop standard code for multiple deployments of the iTRAK system.

iTRAK 5750

Rockwell Automation is expanding the iTRAK line of linear servo conveyors by beefing up the 5730 platform. The new 5750 platform offers larger payloads with the same maximum speed. Just like the 5730, the track is made of modular straight and curved connected sections allowing designers to build a system that is customized to each application.

Just like any motion device, safety is a top priority. The iTRAK 5750 includes safe torque off, satisfying SIL 3 and PLe safety rating. Users can also create safety zones similar to industrial robots. The safety zones allow users to set different safe conditions for each zone. Motion can be halted safely in one zone while motion continues in another.

With each mover treated as an individual servo, users can track the positional data of each mover throughout the system. This data can be traced and analyzed to determine maintenance schedules or collected for machine efficiency calculations. Each mover can be controlled independently, or the motion of multiple movers can be combined to move in a coordinated motion profile.

A DT Engineering display booth showing off new technology from Rockwell Automation. Image courtesy of Rockwell Automation

Servo Conveyor Systems

A typical belt or chain conveyor moves a pallet from station to station until a stop is reached. The stop will hold up the pallet until the downstream station is clear. While this process works well, it is very slow, and designers will often take time to accommodate the slow process and add additional buffer conveyors to make for a faster upstream process. With a servo conveyor, this catch-and-release method isn’t necessary. The system will not allow movers to crash into each other, so the control system doesn’t have to worry about playing traffic cop. When the system is working in harmony, faster processes will make up for slower processes, and bottlenecks can be found immediately. Using a servo conveyor system such as the iTRAK 5750 can provide designers the flexibility to design faster and more efficient automated equipment.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin