Rockwell Makes Automation Look Easy With Updates to ArmorBlock 5000

Integrators and machine builders can automate and maintain systems with greater ease thanks to Rockwell Automation’s enhanced firmware and features for the ArmorBlock 5000 IO-Link device series.

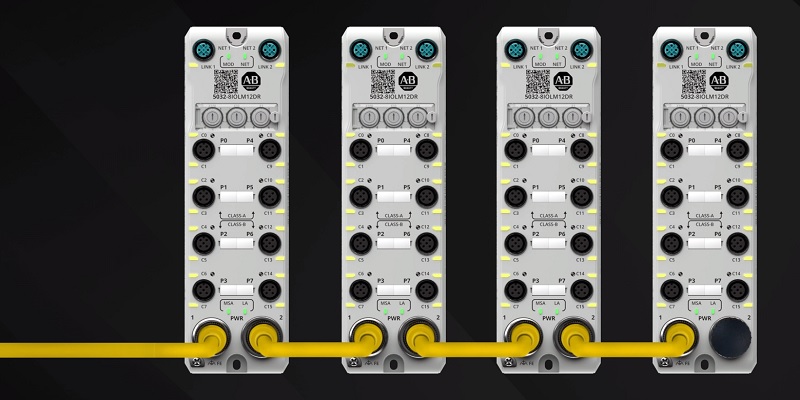

Rockwell Automation has released new firmware and has added a selection of features to the popular ArmorBlock 5000 IO-Link modules from Allen-Bradley. The ArmorBlock 5000 series is one of the go-to choices for machine builders, expanding machine capabilities while boosting functionality in industrial environments thanks to a robust IP69K rating. These new features give Rockwell Automation customers newfound flexibility to manage information through their IO-Link systems.

Enhanced Firmware and Features

You know that sinking feeling you get when you find what appears to be the device with all the perfect specs, only to realize that some subtle configuration prevents compatability with your existing setup? With the ArmorBlock 5000, Rockwell Automation has introduced a generic IO-Link profile, opening doors to a wider range of compatible devices and allowing existing automated systems to be expanded with newer devices.

Rockwell Automation’s ArmorBlock 5000 series now features enhanced features and a new Add-on Profile (AOP) update. Image used courtesy of Rockwell Automation

The next added feature is similar to having a personal assistant built into the IO-Link system. ArmorBlock 5000 series users can utilize a process data only mode. With this feature, communication between devices and the control system is limited to transmitting only the data specified by the IO-Link device.

Rockwell has also added an automatic download of IODD files. For those unfamiliar with IO-Link devices, IODD stands for I/O Device Description. These are files that contain identity, parameters, and much more data associated with the devices attached within the system, which speed up initial and ongoing (replacement) configuration, gaining efficiency for the entire process.

Rockwell has also made it easier to replicate existing machines with an EDS file import/export function. This feature allows EDS files to be exported from previously configured IO-Link master blocks and then can be imported to different machines saving customers time and money, not to mention saving integrators a few headaches from debugging new configurations.

The Armorblock 5000 series can be daisy-chained up to 10A for the M12 4-pin and 5-pin blocks and 16A for the L-coded blocks. Image used courtesy of Rockwell Automation

Finally, let’s talk about flexibility. We know things can change in the blink of an eye, and you need a solution to keep up. That is where the Change Type functionality comes in. Need to replace an IO-Link master block with a different power variant? The Armorblock 5000 series has three power variants! With a selection of change types, you can switch devices and minimize downtime without device or software configuration.

Making Automation Easy!

Thanks to Rockwell, programming and configuring the ArmorBlock 5000 series has been integrated with the popular Studio 5000 and Logix Designer software. The ArmorBlock IO-Link modules were designed for zero-cabinet architecture to reduce automation costs and simplify machine design and development. Each hub is equipped with IO-Link Class A and B ports with light-emitting diodes to easily troubleshoot and monitor each port.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin