Saving Space: Bosch Rexroth Announces Vertical Spiral Transport System

Bosch Rexroth has leveraged the popular modular VarioFlow conveyor system to create a new vertical, spiral conveyor for more efficient transport and buffer storage space.

Bosch is well known around the world in the automation industry for their modular and flexible conveyor systems. Their conveyor product group spans chain conveyors, low-friction belt conveyors, and even a linear servo conveyor system. Conveyors are an important piece of any assembly equipment. They transport products and components to and from assembly stations and are even used to store components for later use. Recently Bosch Rexroth has released a new take on the traditional conveyor, a vertical spiral conveyor.

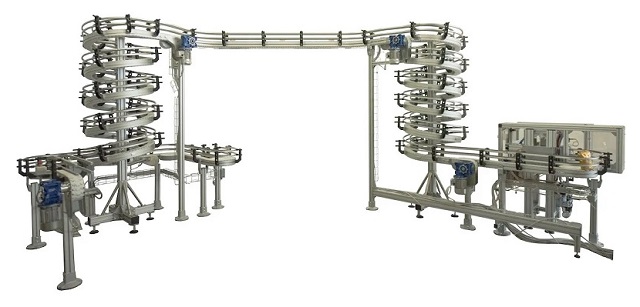

A section of modular, vertical spiral conveyor system. Image used courtesy of Bosch Rexroth

Spiral Conveyor from Bosch Rexroth

In an effort to make transporting and buffering of goods on the factory floor easier and more compact, Bosch Rexroth has designed a spiral vertical conveyor. The spiral transport system is a chain conveyor with numerous configurable properties, including a width of 80 to 320 mm between chains, supporting an incline of 5° to 12°, and is capable of linear speeds of 5 to 60 m/min.

The conveyor has three versions: aluminum, stainless steel, and an FDA-compliant version, all with a max height of 3 m from inlet to outlet. The spiral conveyor can be configured digitally using Bosch’s MTpro engineering tool, in a similar fashion to other conveyors offered by Bosch. The base of the vertical conveyor consists of four adjustable feet to allow for easy installation on the factory floor.

Bosch Rexroth’s VarioFlow conveyor transport system. Image used courtesy of Bosch Rexroth

Transport vs. Buffering

With most large automated assembly equipment, there is a need to buffer assemblies between stations. This allows for sections of the line to stop if there is an issue without affecting upstream processes. The idea is to allow pallets on the conveyor to pile up in front of a station. As downstream stations run faster than upstream stations, the buffer is depleted. When downstream stations stop, the buffer is filled again. This design is very effective but does cost a lot of real estate on the factory floor. By using a vertical conveyor system, the buffer real estate can be drastically reduced.

To complement the range of chain conveyors, Bosch Rexroth cooperates with smartPac, a well-known and experienced manufacturer of spiral conveyors. Image used courtesy of smartPac

Across, or Up And Over?

Often, assemblies need to be transported across walkways in order to get to other assembly equipment. When conveyors would ordinarily need to block walkways, there are special sections that stop traffic and allow operators to lift the conveyor out of the way so that they may pass through. While this is a tried and true system, what if you could raise your conveyor up and over the walkway?

With a vertical spiral conveyor, assemblies can be transported above walkways so that production doesn’t need to stop or be buffered while operators move around the equipment. The raised spiral sections also work as an inline buffer.

Drying Time

In some situations, components or assemblies need time to dry or settle before the next operation and the common method is to use a long winding conveyor to accommodate this settling time. Similar to those previous buffer problems, these long, winding conveyors take up a lot of space on the factory floor. With a vertical spiral conveyor, you can achieve the same settling time with a reduced footprint.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin