SCANTECH Advances Flexible Automated Inspection with AM-CELL C

The AM-CELL C, a robot-agnostic, dynamic, optical automated 3D measurement system by SCANTECH, enhances autonomous inspection in industrial environments.

SCANTECH announced the launch of its AM-CELL C Series Optical Automated 3D Measurement System. The solution is designed to provide customers with high-performance, adaptable inspection of parts, continuous measurements, and standardized quality control. Scantech is a globally recognized provider of 3D scanners and systems for industrial applications covering aerospace, manufacturing, transportation, automotive, and engineering machinery.

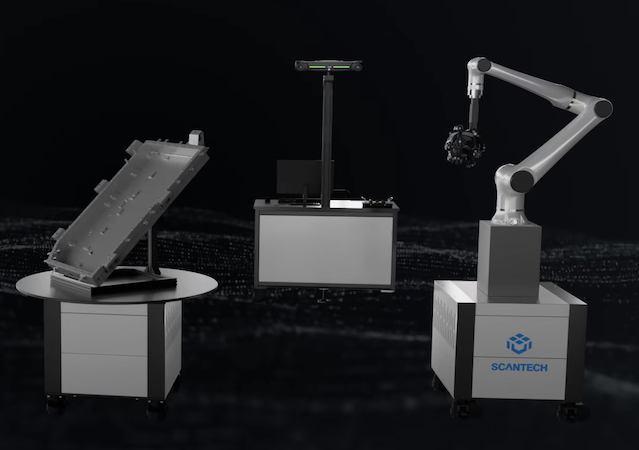

The AM-CELL C Series system combines a Positioner, TrackStation, and Robot Unit. Image used courtesy of SCANTECH

Flexible and Metrology–Grade Measurement

Customers can set up the AM-CELL C in two days and configure the modular system to meet batch inspection requirements across different industrial use cases.

The system integrates robots and controllers alongside intelligent motion control. The AM-CELL C system is compatible with all Scantech scanners, such as the portable NimbleTrack Wireless 3D scanning system and TrackScan-Sharp. NimbleTrack features carbon fiber frame integrated molding to provide a lightweight but robust structure resilient to temperature variations.

The NibleTrack scanner uses a high-capacity battery and added tracker plug-in batteries that provide a dual power cycle. Both scanner and tracker come with edge computing modules, facilitating high frame rate scanning of 120 frames per second. Users can collect 3D data of closed facets such as slots, holes, or rectangular surfaces of machined or stamping parts.

The system maintains a metrology-grade precision of 0.025 mm while achieving a measuring rate of up to 2,600,000 measurements per second. This high accuracy is essential for quality control, guaranteeing that parts fulfill exacting requirements. To verify that parts meet design requirements, it generates comprehensive measurement results that allow for the visualization of GD&T (Geometric Dimensioning and Tolerancing) variations.

A Robot-Agnostic Plug-and-Play System

The AM-CELL C system is robot-agnostic with the ability to integrate different brands of robots with varying lengths of arm (even those over 1300 mm) and teach bots to execute rapid path planning. Customers can employ plug-and-play options and select turntables of varying dimensions and payload (from 200 kg to 1000 kg) to suit specific applications with parts differing by weight and size.

Safety and Software

STANTECH says that advanced servo systems in the robots and positioners give accurate force feedback, eliminating the requirement for further safety precautions. This technology ensures safe engagement by allowing the system to recognize and respond to barriers in real time. This configuration promotes a collaborative workspace by enabling humans to work beside the measuring device without sacrificing safety.

The system includes safety features, including safety light curtains to identify incursions, safety fences to create physical limits, and safety door locks to restrict access to locations with stricter safety standards. By taking these precautions, possible risks are addressed and a secure workplace is maintained.

The AM-CELL C system works alongside the DefinSight-AM automated measurement software. The software offers an Engineer and Operator Mode, the latter enabling quick access to operators with a single click. Once inside, users can read or operate only, ensuring procedures run without disturbance and with little or no risk to operations. The software automatically runs calculations and generates templates and inspection reports.

Engineer Mode allows users to maintain several automated 3D measurement systems through offline programming. Users can review historical measurement results and analyze stats to optimize process control.

Application Areas

The AM-CELL C’s rugged architecture allows human operators to conduct inspections in harsh environments, catering to worker safety and maintaining production throughput.

The dynamic 3D measurement possibilities offered by the AM-CELL C system could provide strict quality control for producing medical devices such as surgical tools and implants that must adhere to safety and functional standards.

Furthermore, the system is suitable for the civil engineering and construction sectors due to its scalability and continuous measurement capability. It could be applied to constant monitoring and structural inspections to make sure safety rules and design standards are followed.

The AM-CELL C system can also be programmed and configured for teaching in an educational setting such as a university, giving students hands-on industry experience in robotic automation and automated inspection.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin