SMC Releases Lightweight, Vacuum-integrated Electric Gripper for Cobots

SMC has released its lightweight, energy-saving ZXPE5 Series electric vacuum gripper for collaborative robots. The new gripper has a built-in vacuum pump and can be used with a single electrical wire connection.

Globally recognized manufacturer of pneumatic control equipment, SMC Corporation (SMC) has released its new ZXPE5 Series lightweight (556 g) electric vacuum gripper. The gripper comes with its own integrated vacuum pump, meaning it can be used with or without an air source.

SMC’s new ZXPE5 Series electric vacuum gripper is designed for use with collaborative robots. Image used courtesy of SMC

ZXPE5 Series Vacuum Gripper

Since the ZXPE5 Series electric vacuum gripper doesn’t need an air source, installation requires one less step and, therefore, less time. This translates to reduced costs and quicker deployment in time-sensitive industrial applications. The gripper’s integrated vacuum pump also makes it more portable. Moving the gripper or reconfiguring it to suit a different workspace setup adds flexibility and supports more adaptable industrial processes.

The lack of additional external connecting cables in a vacuum-integrated design promotes safety in collaborative human-robot work environments. Additionally, external air sources might need more frequent maintenance checks and require more energy for air compression. An integrated vacuum gripper allows for more targeted machine status monitoring and facilitates more effective energy use.

Customers can affix tools by fastening two clamper bolts, as well as fit different types and numbers of cups depending on specific workpiece attributes. Image used courtesy of SMC

Lightweight Energy Savings

Other features of the new ZXPE5 Series gripper include a 360° LED display of device status, three operational modes (automatic, continuous, and manual), and the choice of a variety of cup configurations to suit different workpiece shapes. The automatic and manual modes provide energy savings, and SMC says that its new gripper can save a maximum of 64% on current consumption.

Customers can use a diagnostic function to assess machine health. The function analyzes the starting and current vacuum pressure levels in a state where a workpiece is not under absorption. It also references the factory standard settings and the current values for the maximum vacuum pressure.

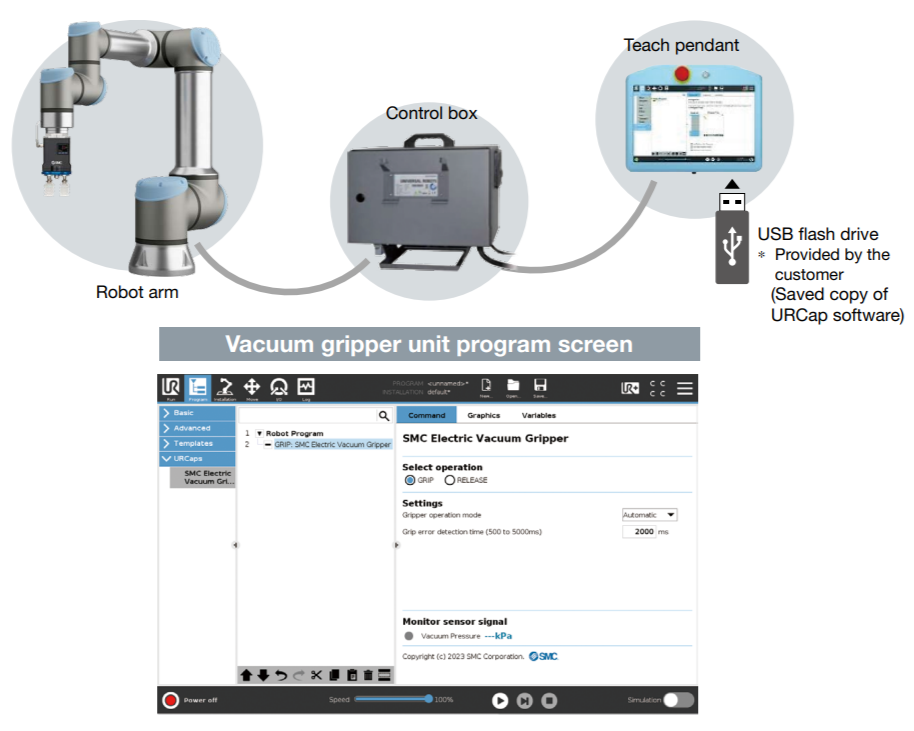

An image showing the vacuum gripper's user interface and the URCap software's initial installation via the teach pendant. Image used courtesy of SMC

URCap Software

Customers can operate the ZXPE5 Series vacuum gripper through a URCap, a Universal Robots certified, user-friendly software. To do this, customers can copy URCap software onto a USB and then install it onto a teach pendant. A URCap is a Java-based plug-in that integrates into UR's graphical programming interface, PolyScope. This kind of plug-in connects a browser and an external Java Runtime Environment (JRE). URCap expands upon PolyScope's capabilities by providing users with intuitively navigable programming screens for creating new programs (for remote management applications) or configuring existing hardware.

A URCap provides users with a setup screen (or installation node) for configuring system coordination, conveyors, the application environment, end effectors, and more. Program commands or nodes are used to set instructions for a particular time within a program sequence. Such instructions can influence the movement of a robot to a particular position, the transportation of a gripped object, or the closing and opening of a gripper.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin