Softing Industrial Embeds tManager on an Industrial PC for IT/OT Integration

The latest industrial PC from Softing Industrial enables users to exchange data upstream and downstream between PLCs and enterprise systems without the need for an extra PLC slot.

Softing Industrial, a popular industrial IT/OT company, has expanded its tManager portfolio by breaking free from brand-specific PLCs and embedding tManager on an industrial PC (IPC).

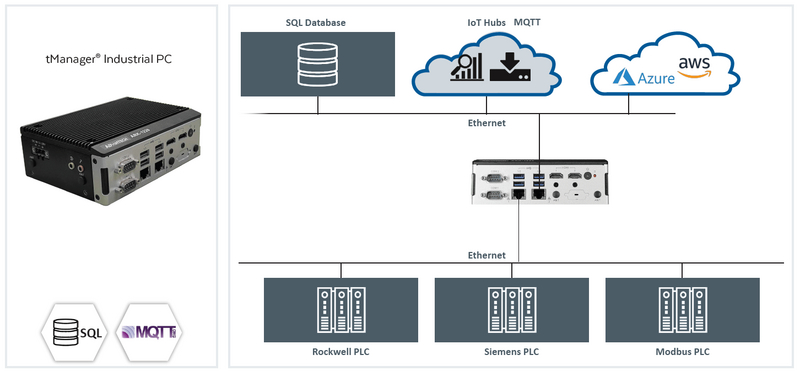

Softing has added an industrial PC to its tManager portfolio. Image used courtesy of Softing Industrial

Softing Expands tManager Portfolio

tManager is a hardware and software portfolio that allows PLCs to connect to relational databases easily. The portfolio consists of a card inserted into a spare slot within a ControlLogix or CompactLogix architecture. The tManager software works similarly to a configuration wizard, where a user selects a few options and provides the software with the necessary information to connect the PLC to the database. This is all done without the need for an edge computer, software coding, or additional servers on the network. Recently, Softing has taken its popular tManager software and embedded it onto an IPC, making the software available to other brands of PLCs.

The tManager industrial PC makes bidirectional data exchange between PLCs and enterprise systems possible. Image used courtesy of Softing Industrial

tManager Industrial PC (IPC)

An IPC is a small industrial computer built to be installed in an industrial environment. IPCs can often be mounted on a DIN rail within an electrical cabinet. Softing’s IPC is a purpose-built IPC for the tManager software, but it is not a traditional IPC. With the tManager IPC, you can configure communications between a Rockwell PLC, Siemens PLC, or any Modbus PLC to any popular database such as Microsoft’s SQL, MySQL, Oracle, or even PostgreSQL. The IPC can even communicate to cloud-based databases such as AWS or Asure. If you are looking for a system to integrate MQTT communications, the tManager IPC can also interface with MQTT brokers.

The IPC has internal storage, and in the event of network failure, up to 2 GB of stored data can be buffered. Once network connectivity is restored, the buffered data will continue to its destination. PLC tags are directly monitored, so there is no need for additional PLC coding. Database responses can be directly tied to tags within the PLC, so there is no additional logic to read from databases.

The IPC acts as a gateway or edge server. No database has been installed, so there is no access to the SQL code. When installing edge servers on the factory floor, this can be a cybersecurity issue. With the tManager IPC, users will not have the ability to create malicious SQL code.

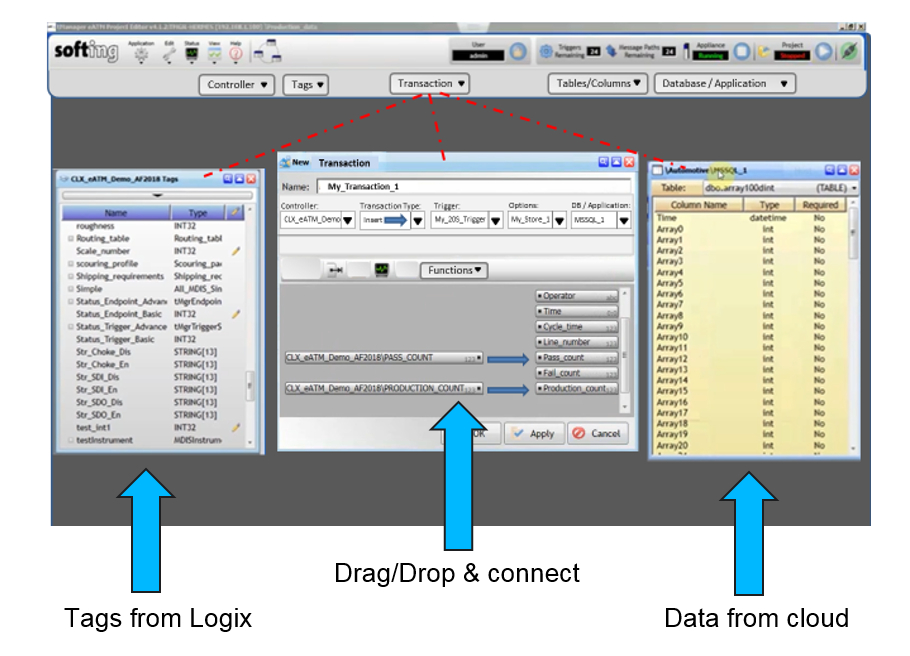

A look at Softing’s tManager interface. Image used courtesy of Softing Industrial

A No Code Solution

Traditional edge servers often require custom APIs and industrial protocols such as OPC to pull data from the PLCs. The custom software can require hours of coding and require specific PC coding resources that most manufacturing companies may not have. Industrial protocols require licensing and can often slow down the PLC scan time with excessive polling. The Softing tManager IPC removes the necessity of building custom APIs or licensing industrial protocols. During the initial integration of the IPC, a user simply provides the embedded software with connection parameters, and an intuitive drag-and-drop screen allows connection between tags within the PLC and inputs or outputs to the database.

Brand Free

Until the release of the tManager IPC, tManager was only available for ControlLogix and CompactLogix PLCs. It was a card that needed to be inserted into the PLC rack, which took up valuable space that could be used for I/O or other specialty cards. With the tManager IPC, you can now use tManager on virtually any PLC on the market. This IPC makes standardizing and spare parts easier to manage, and integrators can be more flexible with PLC choices. The IPC will work with Rockwell, Siemens, and Modbus protocols, which are the most popular PLCs in the industry.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin