Techman Robot Launches High-Payload Cobot With Built-In AI Technology

Techman Robot has released its newest collaborative robot, the TM30S. The TM30S features heavy-lifting power and AI machine learning capability, giving users enhanced robotic capabilities.

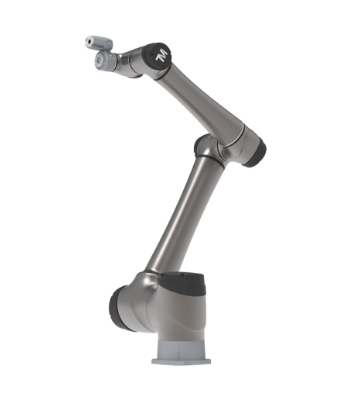

Leading collaborative robot and vision technologies company Techman Robot has released its latest collaborative robot, the TM30S. The new cobot is a high-payload robotic arm intended for palletizing and heavy-duty tasks. With a 35 kg payload, the TM30S is designed to push the boundaries of cobot capabilities.

The TM30S is a high-payload collaborative robot complete with AI vision and machine learning capabilities. Video used courtesy of Techman Robot

The TM30S Collaborative Robot

Techman Robot’s TM30S is designed to be robust and suitable for heavy industrial-type work, including palletizing and packaging, massive pick-and-place jobs, material handling, and heavy machine tending. The TM30S is an extension of the TM AI Cobot S series. It extends the lineup's capabilities by adding a higher maximum payload (35 kg) while maintaining a long reach (1702 mm) with the use of six joints.

With an increased 6th-axis joint speed, the cobot can provide users with a 25% faster cycle time when compared to previous models. In addition, repeatability has been increased by 70% for an accuracy rating within a range of 0.03 mm.

Users can operate the TM30S with Techman Robot’s new “Robot Stick,” which includes a 3-position enabling switch and reset button for a safer and easier operation experience. The stick can control the TM30S alongside the use of a monitor, keyboard, and mouse. The Robot Stick can also be combined with Techman Robot’s optional TM Screen accessory for enhanced teaching, debugging, and control. The TM Screen can help users with easier visualization for on-site debugging and robot control functionality.

The new Robot Stick from Techman Robot can help increase on-site user cobot control. Image courtesy of Techman Robot

Robot Vision and AI Technology

With AI technology, engineers can reduce much of their manual programming. The traditional programming approach can be time-consuming, and the scalability of programming labor is often challenging. AI can help users benefit from AI pattern recognition and machine learning that can learn decision rules automatically. It can help lead to more accurate visual data analysis that may create better efficiency.

Techman Robot’s cobots feature the company’s latest AI technology. The TM30S comes with an AI-capable camera attached to the arm to give valuable visual information to the control system. This ensures that the cobot can handle different vision tasks, including classification, object detection, semantic segmentation, and anomaly detection.

The TM30S is well-suited for heavy-duty palletization tasks. Image used courtesy of Techman Robot

A High Payload for Heavy-Duty Tasks

Techman Robot has designed its TM30S to be a heavy-lifting AI-powered cobot capable of helping with the heaviest tasks. The new cobot is particularly suited for heavy palletizing tasks, like those in semiconductor backend processes where workers often have to lift wafer boxes, sometimes weighing up to 35 kg repeatedly. Whatever its new cobot is tasked with, Techman Robot hopes the combination of heavy-lifting capabilities and AI-driven thinking power will produce an exceptionally functional new combination for its customers.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin