Trial Partnership Tests AI-Powered Technology To Automate Greenhouses

Koidra and Nature Fresh Farms have established a trial partnership to test a new way of farming greenhouse environments using Koidra's AI-powered automation technologies.

Koidra has united with Nature Fresh Farms to integrate advanced artificial intelligence of things (AIoT) technologies into Nature Fresh Farms’ greenhouse operations. Koidra is an intelligent automation solutions provider for industrial manufacturing and large-scale greenhouse industries. Nature Fresh Farms is an independent greenhouse food producer headquartered in Leamington, Ontario, Canada. If successful, the partnership between the two companies will serve as a foundation from which to manage, monitor, and optimize greenhouse operations.

Koidra and Nature Fresh Farms begin their trial partnership, aiming to establish comprehensive and efficient greenhouse management. Image used courtesy of Koidra

Koidra and Nature Fresh Farms

Both Koidra and Nature Fresh Farms seek to increase crop production while ensuring optimal growing conditions to produce quality crops. Adding automated systems is intended to relieve unnecessary and potentially hazardous manual labor, freeing workers to take on other high-level tasks.

Using resources in the most efficient manner possible saves energy, so Nature Fresh Farms intends to leverage Koidra’s tailored AI algorithms to mine sensor data, extrapolate information concerning energy use, and optimize its use for heating, irrigation, and lighting. Not only does this thoughtful practice enhance operational efficiency, but it also helps promote sustainable practices.

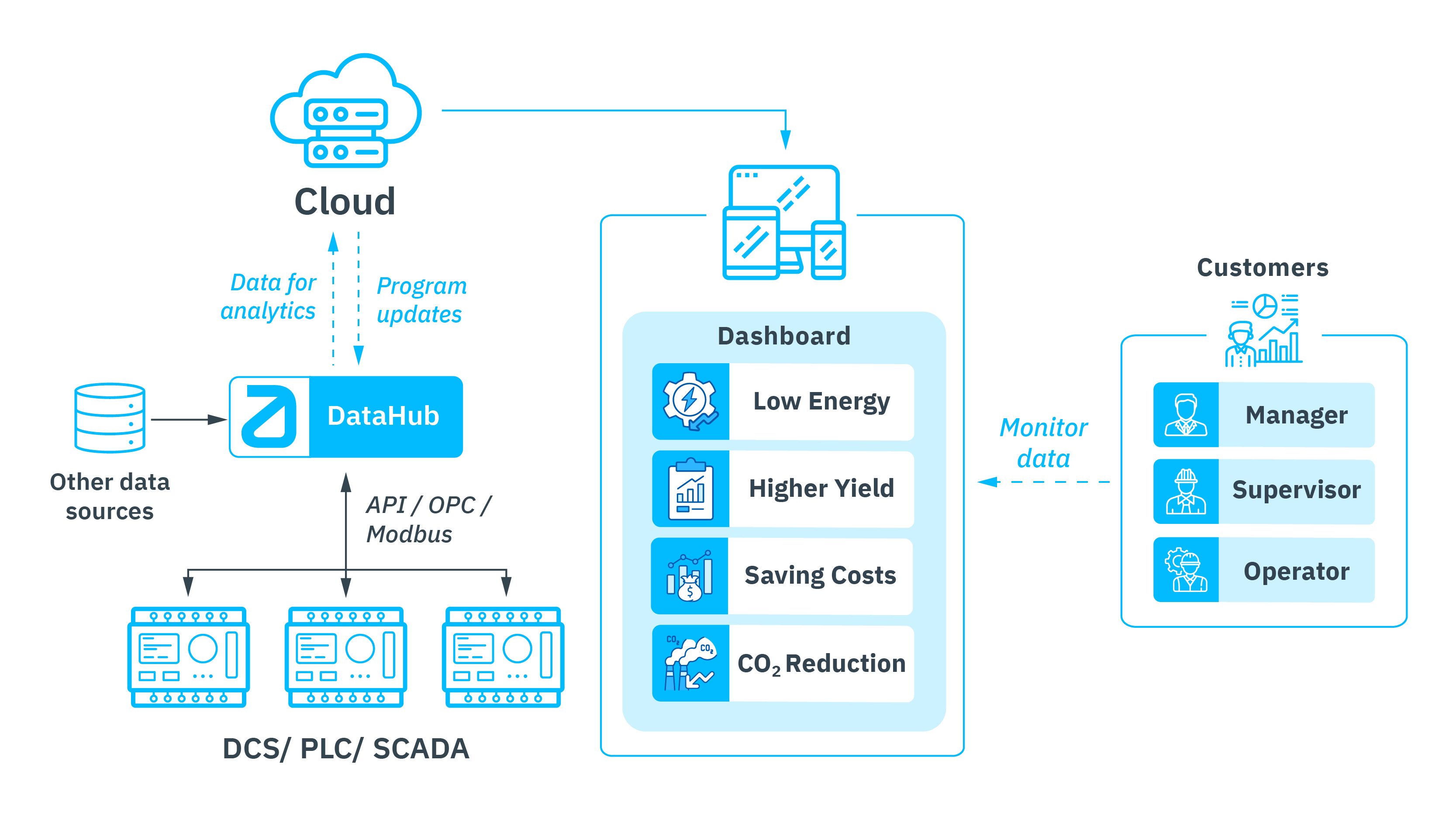

A schematic depicting the various elements of the KoPilot AI-based management system. Image used courtesy of Koidra

AI-powered Automation With KoPilot

The partnership also provides an opportunity to evolve controlled environment agriculture, using AI-based technologies to increase operational transparency, fluidity, and productivity at a greater scale. This evolution applies to traditional and more modern vertical greenhouse environments, which provide the capacity to grow upward and maximize produce output for the world’s growing population.

Koidra’s AI-backed greenhouse management solution, KoPilot, culminates sensor technology and automated systems to provide a complete production overview. It centralizes control setup and utilizes a Data Hub for system upgrades and transferring data to the cloud for advanced analytics. The DataHub connects with PLC, SCADA, and DCS systems, along with other data sources, to pool facility information.

Kopilot features an intuitive user interface with low-code language to increase user accessibility. Operators can alter setpoints to adjust to external conditions and track, oversee, and revert changes made to operations to maintain accountability and ensure consistency and traceability.

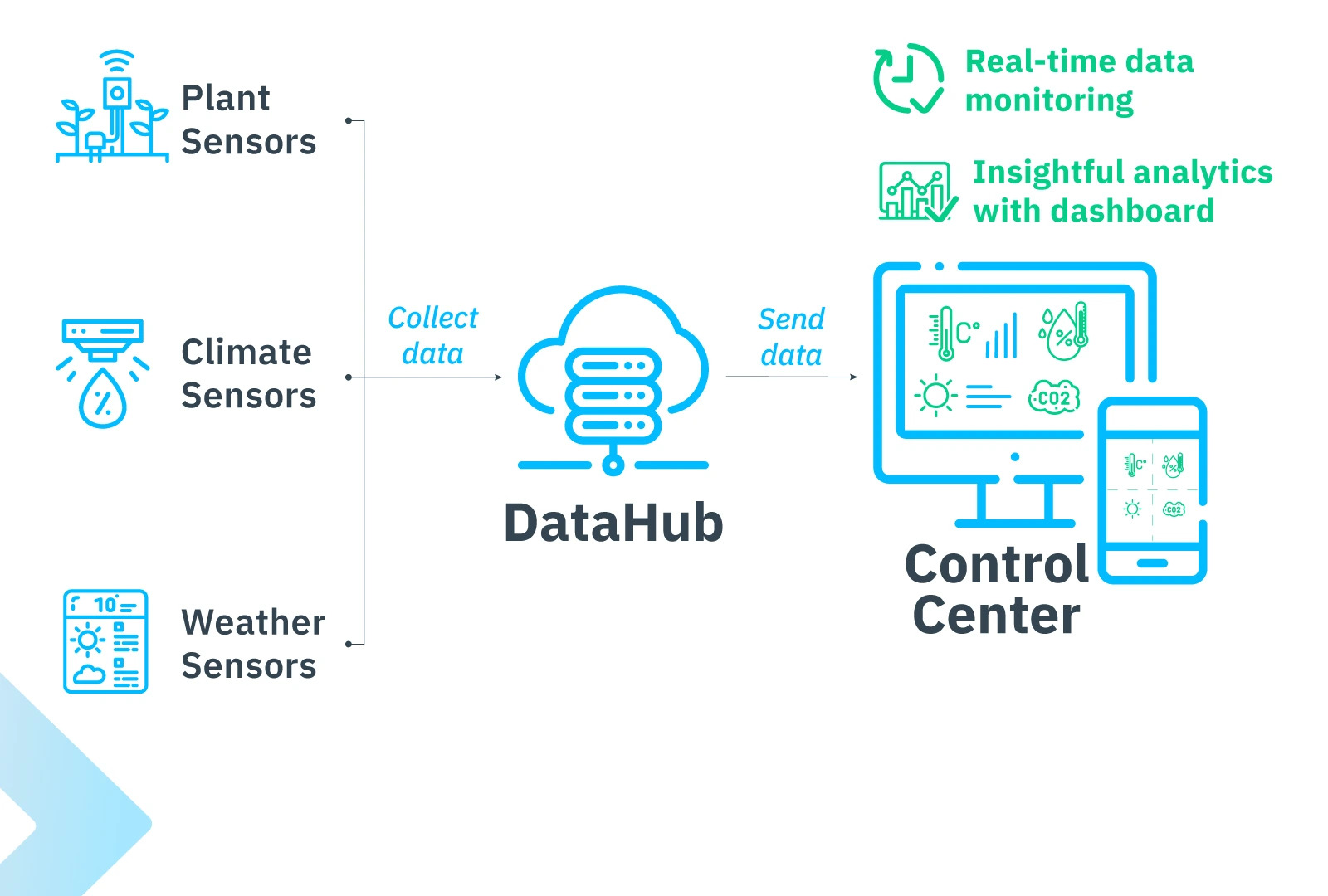

A schematic depicting how Koidra’s DataPilot solution works, connecting sensor data, transferring it to the DataHub, and sending that data to the control center for analysis. Image used courtesy of Koidra

Advanced Analytics With DataPilot

Koidra’s DataPilot solution takes care of advanced analytics, taking sensor data from plant devices and integrating it into a unified platform to provide a one-stop shop for reporting, data visualization, and analysis. Users can access the operational dashboard via mobile devices as well as the control room through the Koidra app to generate real-time insights for process optimization.

Users can utilize a wireless sensor gateway, advanced data aggregation functions (for immediate calculations and visualizations), smart alarms (to provide notifications of any operational glitches), and link up to old control systems (to utilize historical data).

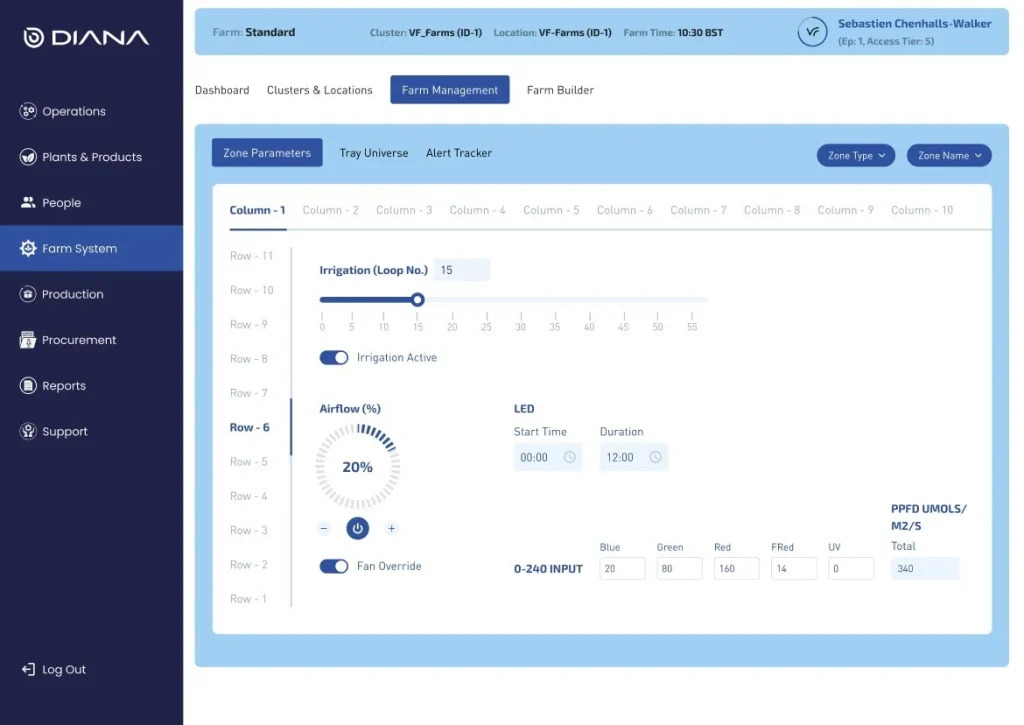

DIANA’s production calendar provides a user-friendly interface to optimize crops. Image used courtesy of Vertical Future

Farming the Future

In light of exploring farming of the future, Vertical Future is another innovative company looking to change the landscape of controlled environment agriculture through innovative hardware and software. Vertical Future’s intricate software-as-a-service solution, DIANA, provides farmers with the tools to monitor, control, and optimize growing workflows.

DIANA comes with an expanding product library with dynamic baseline formulas that allow users to design and improve their product qualities. Customers can modify nutrient levels, lighting, and airflow to achieve optimum crop growth conditions. The Production Calendar maximizes crop yield even while handling a variety of crops with varying needs by optimizing the use of available space. The operational oversight tool also increases overall productivity and collaboration among staff members.

Companies like Nature Fresh Farms, Koidra, and Vertical Future are changing the face of agriculture through AIoT, automated hardware, and advanced management software to save on resources, minimize manual labor, improve yield and crop quality, and achieve sustainable operations. While agritech companies aim to grow and grow more, the focus is also on growing sustainably for the health of consumers and the planet.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin