Turck Releases Q300 and Q180 UHF RFID Read/Write Devices

Could these feature-packed devices be a logical solution to any inventory visibility shortcomings in your factory or warehouse operations?

Turck, a leader in sensors, connectivity, and automation network devices has recently announced the launch of two new sensor products, the Q300 and Q180, to aid in logistics operations where tracking of products and workpieces is critical.

Foundational RFID Technology

Fundamentally, these two devices leverage radio frequency identification (RFID) technology to track objects. The basic architecture consists of antennas and microchips that communicate via a signal. An antenna on the Q300 or Q180 device sends a signal that activates an RFID tag present on the physical object. This tag contains metadata about the object such as identification, location, description, or other data depending on the use case. When ‘struck’ by the signal, the tag transmits this data back to the RFID reader via its own embedded antenna.

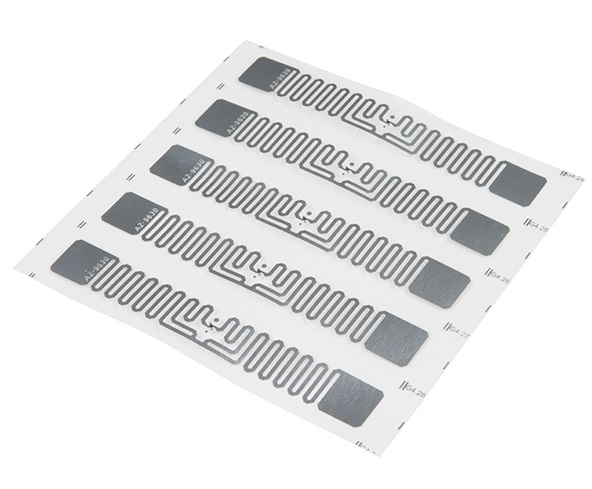

Tags are extremely low cost and ultimately disposable which makes them great for tracking objects in high volume. Lastly, UHF or ultra-high frequency is a sub-category of RFID technology. The “ultra” refers to RFID technology that operates in the frequency range of 860 to 960 MHz. The Q180 and Q300 operate specifically between 902 and 928 MHz and are only suitable for use in North America. The advantage of using UHF frequencies is that it allows the read/write devices to gather data faster and at greater distances than lower frequency options.

A set of RFID tags, with the embedded antennas visible in the circuit traces. Image used courtesy of SparkFun

Long-Range Inventory Applications

The Q300 and Q180 can greatly benefit inventory or component tracking in the logistics or manufacturing industries.

A use case for long-range sensing (a distance of several meters) in the logistics industry is the tracking of inbound and outbound goods in loading bays. A gate can be set up at the entrance to each truck with a Q300 UHF reader. With external antennas attached, the reader can consistently and accurately read or write to all tags contained in the pallet. The tag orientation or position within each of the objects on a pallet is not significant; the Q300 will detect the tags.

Warehouse gate example with a Q300 reader device tracking palletized inventory. Image used courtesy of Turck

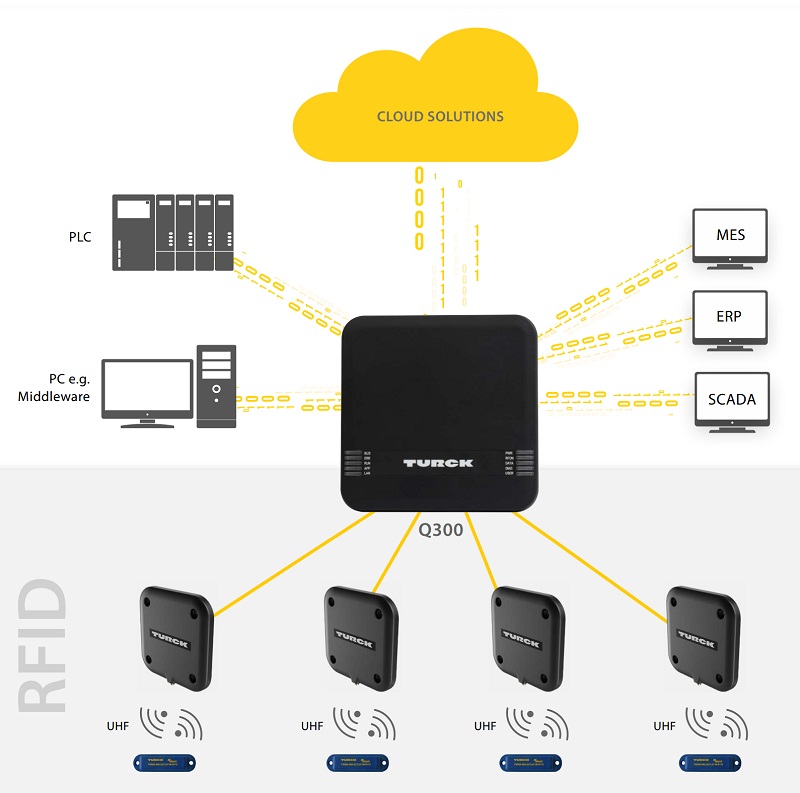

A single Q300 unit can be used in the above use case, in contrast to other models and vendors since up to 4 external antennas can be attached to the reader unit. The units also have a wired M12 ethernet connection that allows for power over ethernet and fast, reliable data transfer speeds to various ERP, MES, or SCADA systems.

Up to 4 external antennas can be attached to the Q300 and Q180. Image used courtesy of Turck

Short-Range RFID Applications

An example of a short-range application, or approximately 1 meter, is the position detection of components during production. The automotive industry is a notable success story of such use cases. The antennas attached to the Q300 or Q180 determine the range. Shorter range antennas can be attached to the Q300 or Q180 to accurately identify the location of a single component in a production line. One such example is the tracking of wheels in a production line. The contrast single-tag detection, compared to the multi-tag detection in the logistics example, shows the versatility of these devices.

Software and Communication

The Q180 and Q300 offer several modes of communication and software platforms. The most flexible option offered is a base Linux operating system. This system does not natively provide any application or integration capabilities but is an open-source and robust operating system often used as a foundation in industrial IoT.

The devices also come standard with the CODESYS V3 platform, which can be considered a SaaS solution. The runtime executes the control logic on the Q180 or Q300 and can be programmed in a development environment included with the software. CodeSys OPC-UA server is also included as an option. Various communication protocols are supported by the device lineup, including Modbus TCP, PROFINET, and EtherNet/IP.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin