Wengler’s New Photoelectric R-Series Sensors Offer Reliable Detection

The R-series sensors from Wengler offer consistent sensing, even through transparent objects. They utilize retro-reflex technology and come in three variants.

Wenglor has released a new lineup of retro-reflex and reflex photoelectric sensors, establishing new benchmarks in reliability and user-friendliness. With three variants, Wenglor’s latest enhancement for R-design photoelectric sensors presents a highly adaptable choice in the market.

The R-design photoelectric sensor portfolio includes P1RH, P1RK, and P1RL models. These sensors are designed to meet various automation market needs. The P1RH reflex sensors have a background suppression function, making them suitable for automated packaging lines where the conveyor belt and background elements must be ignored. The P1RK retro-reflex sensor can detect transparent objects like glass, bottles, or film. Lastly, the P1RL retro-reflex sensor is versatile and can handle a wide range of high-speed needs without requiring specific details.

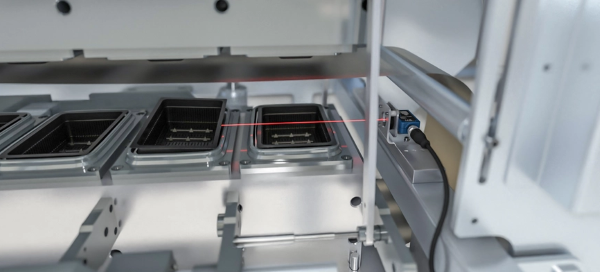

The three sensor models, the P1RH, P1RK, and P1R, effectively detect transparent objects. Image used courtesy of Wenglor

The difference between Retro and Retro-Reflex

To explore the sensors' advanced features and functions fully, it's essential to first address a common question when discussing retro and retro-reflex: What exactly sets the two apart?

The P1RH reflex sensor detects objects using red light and offers background suppression. It is designed to ignore backgrounds and be insensitive to shape, color, and surface finishes. On the other hand, retro-reflex sensors use different light sources, with the emitter and receiver located in the same housing. If something gets between the sensor and the reflector and breaks the light beam, the sensor will generate a signal.

The differences in working principles also affect the sensors' range and switching frequency capabilities. Wenglor's universal retro-reflective sensors can detect objects up to 12,000 mm away, while their retro-reflective sensors for transparent objects range up to 4,000 mm.

Additionally, the reflex sensor with background suppression has a limited detection range of up to 120 mm. The reflex sensor has a 1,000 Hz switching frequency, while the retro-reflective sensors have a switching frequency of up to 2,000 Hz. These differences should be taken into account when working on high-speed applications.

This image showcases one of Wenglor’s retro-reflex sensors detecting a tray that is out of position. This detection prevents the sealing process from being carried out incorrectly. Image used courtesy of Wenglor

Advanced Functions of the P1RH, P1RK, and P1RL

User-friendliness is a significant selling point of Wenglor's new sensors. The three sensors introduced in the R-design feature an integrated central teach button. This button simplifies setup by offering automatic calibration based on the application's current environment. The process is as easy as mounting the sensor and reflector in place (if the reflector is needed per model) and holding the teach-in key for two seconds until the switching status indicator (LED A1) begins to flash. Once the calibration is complete, the distance is taught, and the sensor can be tested. Additionally, the sensor's teach key can also be used to change from normally open to normally closed and to change teach-in modes.

There are four different teach-in modes, including normal teach-in and minimum teach-in, both with a normally open or normally closed option. The differences between these teach-in modes lie in the signal strength. With minimum teach-in, considering the signal quality, the switching point is set below the momentary signal strength. However, with normal teach-in, the switching point is set to a value corresponding to half of the signal strength. Due to its sensitivity, the normal teach-in mode is better suited for detecting opaque objects.

Wenglor’s new R-design sensors also feature an IO-Link interface. The IO-Link communication protocol ensures easy parameter configuration, provides an output signal value, and gives insight into condition monitoring and the setting of on-and-off delays.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin