What is Height-Based Laser Sensing? Technology from Keyence Brings New Inspection Capabilities

Keyence released an image-based laser sensor used for detecting and scanning defects across an entire area.

Keyence has been manufacturing imaging, laser measurement, and inspection systems for industrial automation since 1974. Specifically, they have been manufacturing bar code readers, digital microscopes, laser systems, machine vision, and cameras. Their products are used for inspection and positioning of parts in manufacturing including the latest line of laser measurement, the IX-H.

This platform is designed for inspection and quality assurance purposes in manufacturing and has some distinct advantages over other automated inspection methods. Their website shows an example of this system, detecting an improperly tightened bolt, which shows up as “NG” for “No Go”, versus the “OK” output for a properly tightened bolt.

Image-Based Laser Sensing and Inspection

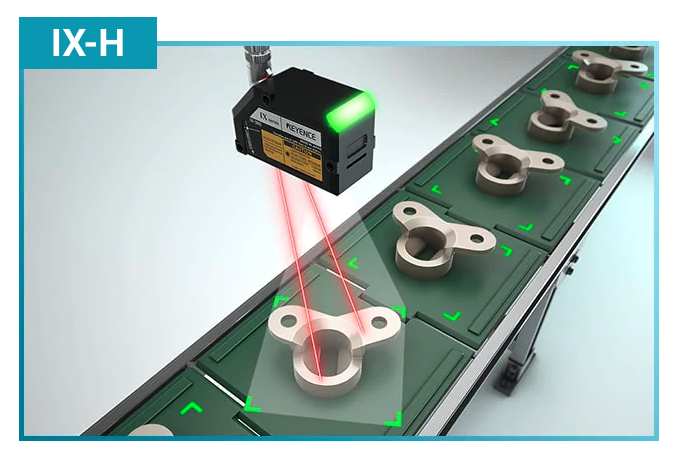

Image-based laser inspection techniques offer some major advantages over machine vision solutions. With image-based laser systems, part orientation is not important. The laser system can evaluate each part and adjust its orientation in software to make the final inspection decision. The IX-H also works great for low-contrast situations, or highly-reflective situations, where machine vision cameras can be fooled more easily.

The new IX-H image-based laser inspection. Image courtesy of Keyence.

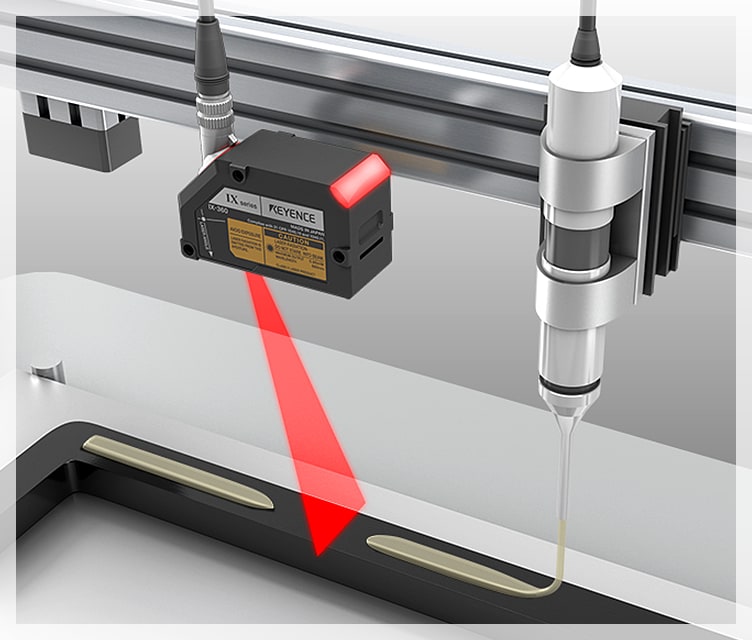

Image-based area laser inspection also has advantages over traditional laser systems. The area inspection allows for much finer detail resolution than a simple point-based laser system. With area laser inspection, small parts can be detected, connector pins can be checked for consistency in size and depth, and the thickness and uniformity of adhesives can be examined.

The IX-H Series

The IX-H series lasers can be ordered in several configurations, depending on the size and resolution required, as well as the standoff distance between the sensor and the parts to be inspected. For close-up inspections (55 mm, or 2.17 in), the IX-055 can detect height differences of 0.1 mm (0.0118 in), and for far-away inspections (360 mm, or 14.17 in) of larger objects, the IX-360W can detect height differences of 1 mm (0.040 in).

The new IX-H image-based laser inspection. Image courtesy of Keyence.

The IX-H series lasers can be combined with a stand-alone control panel or connected to a regular computer and can communicate over standard industrial protocols, such as RS-232, TCP/IP, EtherCAT, and others. Keyence offers seven different mounting brackets to ensure that there is a mounting solution for virtually every industrial situation.

Automatic Inspection in Manufacturing

These systems are designed to make an impact on automated inspection in manufacturing. They can catch a misaligned seal, bent connector, cross-threaded or improperly tightened bolt or screw, defect in a rubberized coating, and so on.

The new IX-H image-based laser inspection. Image courtesy of Keyence.

More importantly, these types of inspections can be done automatically, regardless of the part’s orientation when it passes by the laser sensor. Parts can be inspected quickly and accurately, without sending parts to be manually inspected that need no further inspection.

It has the potential to reduce the false positives for defect detection, which will increase throughput in the inspection and quality assurance department of manufacturing operations.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin