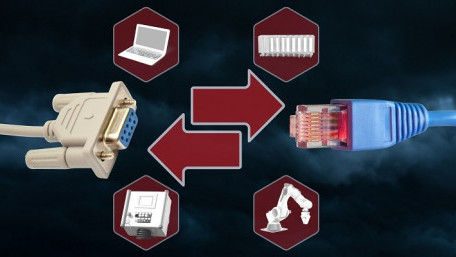

One common challenge when working with legacy control systems is establishing communication with old devices that use old protocols like RS232 and RS485. Learn…

One common challenge when working with legacy control systems is establishing communication with old devices that use old protocols like RS232 and RS485. Learn about the importance of converting from serial to Ethernet.

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In…

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In this article, we will look at PLC programming of fieldbus manifolds highlighting Festo's CPX layout.

Industry 4.0 impacts all parts of the value chain, including logistics, which makes smart logistics a key aspect of…

Industry 4.0 impacts all parts of the value chain, including logistics, which makes smart logistics a key aspect of digital transformation. In this article, learn about the smart logistics cycle and selecting the right components for the tools needed.

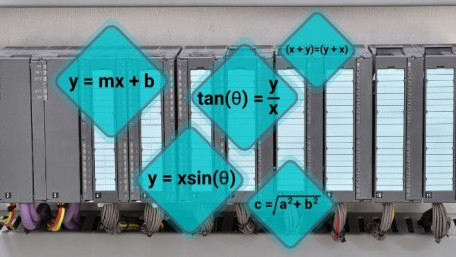

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean,…

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean, well-organized, and easy-to-use code that allows you and other users to troubleshoot your programs.

Industrial robots are a valuable investment because of their speed and accuracy. However, failing to establish the tool…

Industrial robots are a valuable investment because of their speed and accuracy. However, failing to establish the tool center point (TCP) can decrease the accuracy, effectiveness, and ROI for a robot workcell.

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial…

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial manufacturing by remotely identifying problems with electric motors and generators.

Communication protocols are a key component for an industry 4.0 compliant facility and are used to enable communication…

Communication protocols are a key component for an industry 4.0 compliant facility and are used to enable communication back and forth between cloud servers to transmit data or receive instructions.

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and…

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and Automation Direct Productivity Suite.

Software obsolescence poses a threat in industrial automation equal to hardware obsolescence and should not be…

Software obsolescence poses a threat in industrial automation equal to hardware obsolescence and should not be overlooked. Many PLC OEMs offer tools to migrate upgraded software projects to the newest controller revisions.

The HART protocol enables instruments to send analog and digital signals over the same physical wire. This provides…

The HART protocol enables instruments to send analog and digital signals over the same physical wire. This provides multiple advantages for remote configuration, increased accuracy, and more.

Configuring analog signals into usable digital quantities is accomplished by scaling function inside the PLC, which,…

Configuring analog signals into usable digital quantities is accomplished by scaling function inside the PLC, which, along with analog signal wiring, is important to understand.

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement…

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational insights about machine performance statistics.

Designing an obsolescence mitigation plan to detect and solve mitigation risks before they occur is key to avoiding…

Designing an obsolescence mitigation plan to detect and solve mitigation risks before they occur is key to avoiding costly downtime and a potential catastrophe in control environments.

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common…

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common instruction is the one-shot, capable of harnessing the incredible processing speeds in a CPU.

Two major recognitions of Universal Robots’ education programs from the U.S. federal Advanced Robotics for…

Two major recognitions of Universal Robots’ education programs from the U.S. federal Advanced Robotics for Manufacturing Institute (ARM) and the State of Ohio’s Department of Education pave the way for schools and industry to further leverage cobots, offering employability in robotics careers while upskilling existing workforce.

Control engineering is integrally woven together with electricity and electrical circuits. Even so, sometimes the most…

Control engineering is integrally woven together with electricity and electrical circuits. Even so, sometimes the most basic scenarios become misunderstood through lack of training or experience.

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and…

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and unavailable, and the lack of an upgrade plan can turn a simple failure into a catastrophe.

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the…

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the world of control systems. Learn how the hardware platforms have evolved into the familiar modern configurations.

Universal Robots has reached a new milestone with 100 certified training centers worldwide. This comes following the…

Universal Robots has reached a new milestone with 100 certified training centers worldwide. This comes following the opening of a new center in Täby near Stockholm in Sweden, with other centers spread across 23 countries.

Understand the practical steps you might take to integrate artificial intelligence with your maintenance program and…

Understand the practical steps you might take to integrate artificial intelligence with your maintenance program and access the benefits of PdM.