Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers are necessary to implement IIoT in an…

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers are necessary to implement IIoT in an industrial setting to benefit varying processes.

There are many considerations when selecting a thermocouple type. In this article, we look at the advantages, and…

There are many considerations when selecting a thermocouple type. In this article, we look at the advantages, and limitations, of the eight standard thermocouples and various installation considerations.

B&R is a control system manufacturer less heard of than some of its bigger competitors, Rockwell and Siemens, however…

B&R is a control system manufacturer less heard of than some of its bigger competitors, Rockwell and Siemens, however their PLCs, lineup of motors, and product offerings with Automation Studio make B&R a leader in industrial innovation.

Software distribution models have historically been on premises, however, as industry has become more digital,…

Software distribution models have historically been on premises, however, as industry has become more digital, cloud-based solutions have become increasingly popular, including SaaS and its variants, IaaS and PaaS.

Any machine can become a source of elevated temperature, even under regular operation. We cannot assume that temperature…

Any machine can become a source of elevated temperature, even under regular operation. We cannot assume that temperature problems occur only based on climate conditions, and mitigation steps must be employed.

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These…

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These remain the top concern of many manufacturing businesses, but as improvements are rolled out, more and more companies are adopting cloud solutions.

Grounding transformer connections presents its own set of challenges. This article addresses these challenges and several…

Grounding transformer connections presents its own set of challenges. This article addresses these challenges and several common configurations for control transformer grounding.

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime.…

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime. Learn about the ways extreme heat can damage automated equipment and systems.

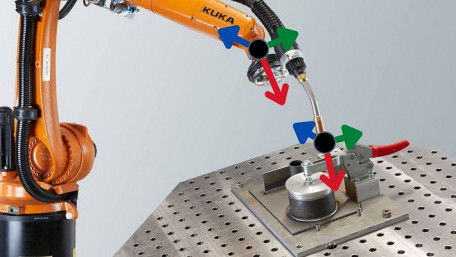

Robots must be moved using cartesian frames to coordinate motion of all the joints. Properly defining the tool center…

Robots must be moved using cartesian frames to coordinate motion of all the joints. Properly defining the tool center point greatly simplifies teaching for any type of end of arm tool (EoAT).

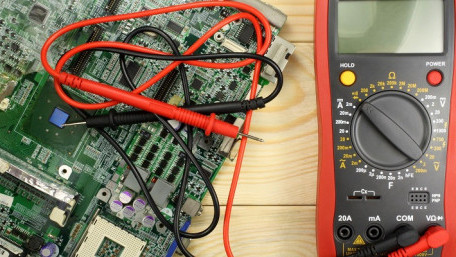

Today’s digital multimeters (DMMs) are inexpensive, accurate, and easy to use, but sometimes a problem with the circuit…

Today’s digital multimeters (DMMs) are inexpensive, accurate, and easy to use, but sometimes a problem with the circuit or the measurement can cause incorrect readings. Learn to interpret and fix these problems.

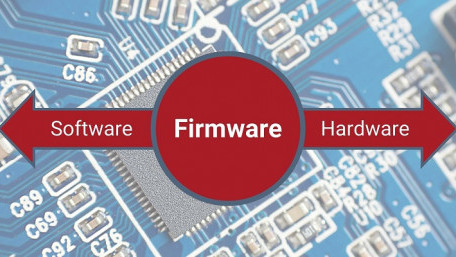

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and…

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and registers, and even the communication of network signals. This is the job of firmware.

Fuses and breakers are some of the most common safeguards to prevent electrical shock and fires. Learn about these two…

Fuses and breakers are some of the most common safeguards to prevent electrical shock and fires. Learn about these two pieces of industrial equipment and the difference between slow blow and quick blow responses.

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with…

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with perhaps the most basic: how do you program industrial robots?

Robot cells make for an efficient automation process, reduce labor costs, and increase worker safety. Learn about the…

Robot cells make for an efficient automation process, reduce labor costs, and increase worker safety. Learn about the common features, components, and safety requirements of industrial robot work cells.

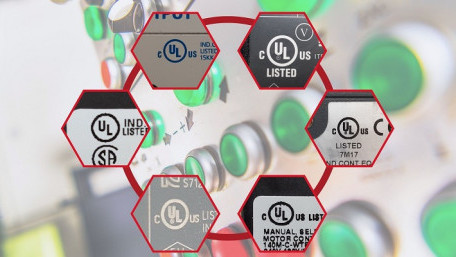

UL Listed devices are certified as safe within North America, specifically, the US. Learn about the importance of UL…

UL Listed devices are certified as safe within North America, specifically, the US. Learn about the importance of UL Certification and the key role it plays in industrial automation.

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their…

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their advantages and disadvantages when it comes to choosing which one to use in manufacturing.

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when…

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when these systems should be bonded with the earth ground of the AC line voltage supply.

Singularity in robotics can be problematic for programmers and manufacturers alike. We will investigate the cause of…

Singularity in robotics can be problematic for programmers and manufacturers alike. We will investigate the cause of singularities and how prevention can be considered in the design of a robot cell.

We will show you how to recognize, utilize, and efficiently operate your comparison instructions in…

We will show you how to recognize, utilize, and efficiently operate your comparison instructions in Rockwell Automation’s Studio 5000 and Automation Direct’s Productivity Suite to make your program flow smoothly.

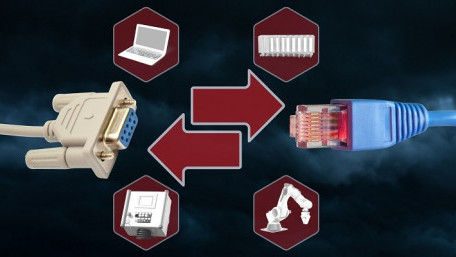

One common challenge when working with legacy control systems is establishing communication with old devices that use old…

One common challenge when working with legacy control systems is establishing communication with old devices that use old protocols like RS232 and RS485. Learn about the importance of converting from serial to Ethernet.