Remote locations are notoriously difficult to supply power, yet they are the exact locations where many data points must be collected. How can IoT devices be…

Remote locations are notoriously difficult to supply power, yet they are the exact locations where many data points must be collected. How can IoT devices be designed to conserve power to last for months or even years?

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers…

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers are necessary to implement IIoT in an industrial setting to benefit varying processes.

Robots are no longer unanimously just "robots"—there are specific tasks and functionality of each kind. Learn about the…

Robots are no longer unanimously just "robots"—there are specific tasks and functionality of each kind. Learn about the technology differences between fixed-location robots and mobile robots and why no one robot is like another.

There are many considerations when selecting a thermocouple type. In this article, we look at the advantages, and…

There are many considerations when selecting a thermocouple type. In this article, we look at the advantages, and limitations, of the eight standard thermocouples and various installation considerations.

Software distribution models have historically been on premises, however, as industry has become more digital,…

Software distribution models have historically been on premises, however, as industry has become more digital, cloud-based solutions have become increasingly popular, including SaaS and its variants, IaaS and PaaS.

Any machine can become a source of elevated temperature, even under regular operation. We cannot assume that temperature…

Any machine can become a source of elevated temperature, even under regular operation. We cannot assume that temperature problems occur only based on climate conditions, and mitigation steps must be employed.

When selecting the right module for the right load, be sure to understand how the load resistance will affect the voltage…

When selecting the right module for the right load, be sure to understand how the load resistance will affect the voltage and current of the output module terminals.

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These…

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These remain the top concern of many manufacturing businesses, but as improvements are rolled out, more and more companies are adopting cloud solutions.

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime.…

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime. Learn about the ways extreme heat can damage automated equipment and systems.

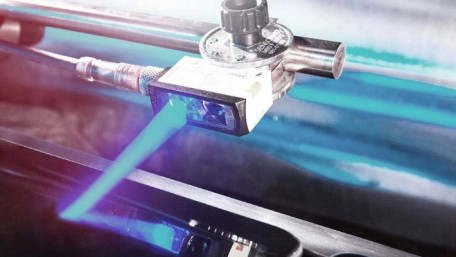

Learn about the differences between red, green, infrared, and more recently, blue photoelectric sensors and how the…

Learn about the differences between red, green, infrared, and more recently, blue photoelectric sensors and how the different light spectrums can aid in varying industrial automation processes.

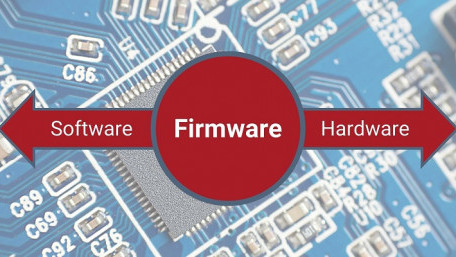

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and…

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and registers, and even the communication of network signals. This is the job of firmware.

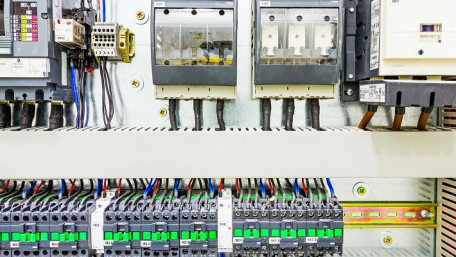

Fuses and breakers are some of the most common safeguards to prevent electrical shock and fires. Learn about these two…

Fuses and breakers are some of the most common safeguards to prevent electrical shock and fires. Learn about these two pieces of industrial equipment and the difference between slow blow and quick blow responses.

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with…

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with perhaps the most basic: how do you program industrial robots?

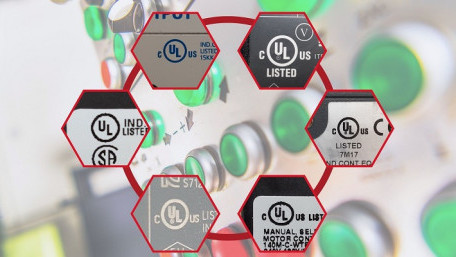

UL Listed devices are certified as safe within North America, specifically, the US. Learn about the importance of UL…

UL Listed devices are certified as safe within North America, specifically, the US. Learn about the importance of UL Certification and the key role it plays in industrial automation.

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their…

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their advantages and disadvantages when it comes to choosing which one to use in manufacturing.

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when…

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when these systems should be bonded with the earth ground of the AC line voltage supply.

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In…

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In this article, we will look at PLC programming of fieldbus manifolds highlighting Festo's CPX layout.

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and…

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and Automation Direct Productivity Suite.

The HART protocol enables instruments to send analog and digital signals over the same physical wire. This provides…

The HART protocol enables instruments to send analog and digital signals over the same physical wire. This provides multiple advantages for remote configuration, increased accuracy, and more.

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement…

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational insights about machine performance statistics.