Safety is one of the most critical aspects of machine design. Today, with network connections between different machines and control centers, safety signals must…

Safety is one of the most critical aspects of machine design. Today, with network connections between different machines and control centers, safety signals must be shared logically and reliably across networks.

Many worldwide plants are still running the old Advant Controller 450 from ABB in their facility, with many plants using…

Many worldwide plants are still running the old Advant Controller 450 from ABB in their facility, with many plants using the latest System 800xA DCS interfaced with the existing AC450 controller.

Servers are vital to the flow of information in and around organizations, acting as a hub for information transfer and…

Servers are vital to the flow of information in and around organizations, acting as a hub for information transfer and storage. Learn about the role of servers in industry and the potential challenges that come with maintaining them.

Despite the many overlaps, PLCs and RTUs are two different devices, each with specific suitable applications.

Despite the many overlaps, PLCs and RTUs are two different devices, each with specific suitable applications.

Network switches allow the interconnection of devices and controllers across a facility, with particular features that…

Network switches allow the interconnection of devices and controllers across a facility, with particular features that make them a good fit for industrial applications. We introduce a few of the leading manufacturers of these products.

The PCU400 can handle all known industrial protocols and forward them to the master station to get an effective…

The PCU400 can handle all known industrial protocols and forward them to the master station to get an effective connection between the SCADA system and the data from the manufacturing or system process.

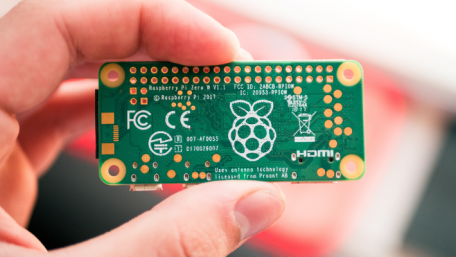

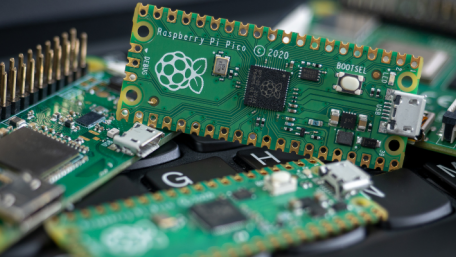

Though not a direct replacement for PLCs, Raspberry Pi has the potential to be used in industrial automation applications…

Though not a direct replacement for PLCs, Raspberry Pi has the potential to be used in industrial automation applications for prototyping, embedded systems, and as a low-cost process controller.

Raspberry Pi is a low-cost, educational single-board computer platform with the potential for industrial applications. In…

Raspberry Pi is a low-cost, educational single-board computer platform with the potential for industrial applications. In this article, we discuss the purpose of Raspberry Pi as well as its hardware and software.

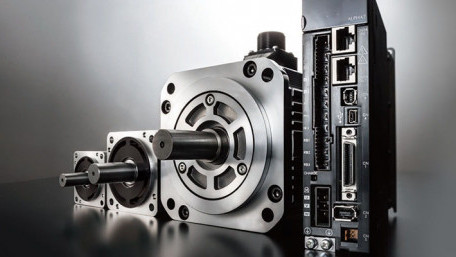

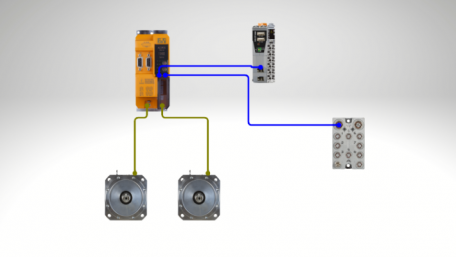

Explore the design of a servo pick and place sample case using B&R Automation Studio, from the project creation to the…

Explore the design of a servo pick and place sample case using B&R Automation Studio, from the project creation to the configuration of the controller, drives, and motion axes.

Arduino’s open-source, microcontroller-based platform has revolutionized academic and hobbyist spaces, providing a low…

Arduino’s open-source, microcontroller-based platform has revolutionized academic and hobbyist spaces, providing a low cost, accessible introduction to engineering and programming.

By shaping new concepts and business models, the IIoT is bringing more efficiency and capacity to automated systems. Take…

By shaping new concepts and business models, the IIoT is bringing more efficiency and capacity to automated systems. Take a look at some of the ways the IIoT is revolutionizing the manufacturing and automation sectors.

All real-time power system data can be communicated to a central control system to protect main equipment from…

All real-time power system data can be communicated to a central control system to protect main equipment from overloading. Learn how to create a project directory structure, hardware configuration, and set network tree parameters for real-time control and monitoring.

As the IIoT continues to grow in the industrial sector, businesses face a number of obstacles to integrating its…

As the IIoT continues to grow in the industrial sector, businesses face a number of obstacles to integrating its solutions. Learn about these challenges as well as some potential solutions.

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers…

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers are necessary to implement IIoT in an industrial setting to benefit varying processes.

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These…

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These remain the top concern of many manufacturing businesses, but as improvements are rolled out, more and more companies are adopting cloud solutions.

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells,…

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells, which are often simpler and less expensive than industrial robot work cells.

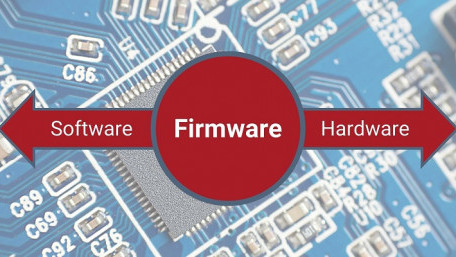

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and…

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and registers, and even the communication of network signals. This is the job of firmware.

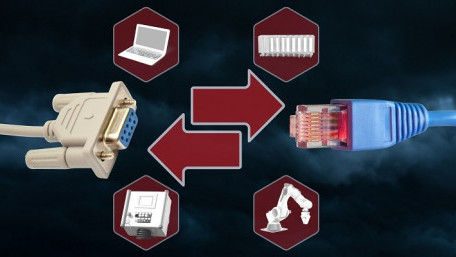

One common challenge when working with legacy control systems is establishing communication with old devices that use old…

One common challenge when working with legacy control systems is establishing communication with old devices that use old protocols like RS232 and RS485. Learn about the importance of converting from serial to Ethernet.

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In…

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In this article, we will look at PLC programming of fieldbus manifolds highlighting Festo's CPX layout.

Communication protocols are a key component for an industry 4.0 compliant facility and are used to enable communication…

Communication protocols are a key component for an industry 4.0 compliant facility and are used to enable communication back and forth between cloud servers to transmit data or receive instructions.