This article will explore the setup of Node-RED, the glue that will serve to connect all of the individual components of the solution that we have created up to…

This article will explore the setup of Node-RED, the glue that will serve to connect all of the individual components of the solution that we have created up to this point.

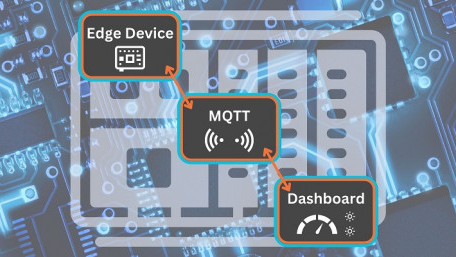

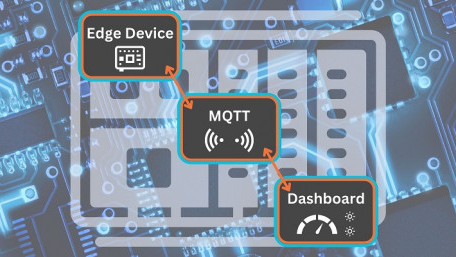

Now that our IIoT project has verified the transmission of an MQTT data payload packet, this next article will explore…

Now that our IIoT project has verified the transmission of an MQTT data payload packet, this next article will explore the setup of an InfluxDB database to store the incoming sensor data.

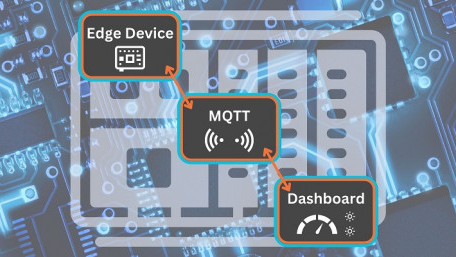

Continuing the real-world IIoT project, learn how to begin integrating the Raspberry Pi with the Mosquitto Broker and…

Continuing the real-world IIoT project, learn how to begin integrating the Raspberry Pi with the Mosquitto Broker and understand Docker networks and port binding.

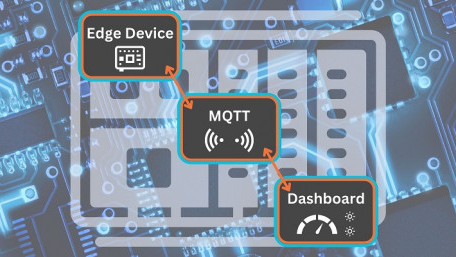

Learn to develop an actual IoT solution end to end. Create a Mosquitto MQTT broker for the Raspberry Pi client in order…

Learn to develop an actual IoT solution end to end. Create a Mosquitto MQTT broker for the Raspberry Pi client in order to connect and publish Sense HAT sensor data.

Every so often, a new data format comes along, and we first consider that it might simply be a mistake in typing. Pulse…

Every so often, a new data format comes along, and we first consider that it might simply be a mistake in typing. Pulse Frequency Modulation (PFM) is not brand new, but still unknown to many engineers.

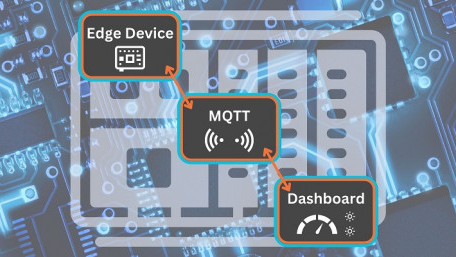

Learn to develop an actual IoT solution end to end, from the initial data collection to web-based visualization and…

Learn to develop an actual IoT solution end to end, from the initial data collection to web-based visualization and analytics. This first article in the series will explore the setup of the edge device.

Many signal sources and process transmitters do not include isolation, which can cause problems when the instruments are…

Many signal sources and process transmitters do not include isolation, which can cause problems when the instruments are at different locations. A loop powered isolator is often the solution.

If you’re working collaboratively with teams in a corporate industrial setting and require a version control system for…

If you’re working collaboratively with teams in a corporate industrial setting and require a version control system for critical software or documents, Git is a must-have in your skillset.

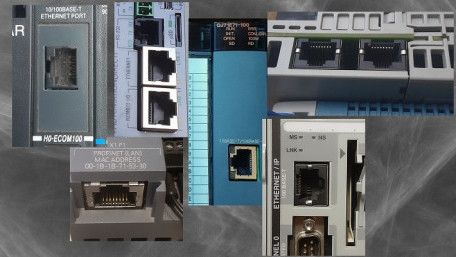

Some controllers and network devices have one port, while others have two. Why is there a difference, and what advantages…

Some controllers and network devices have one port, while others have two. Why is there a difference, and what advantages does having two network ports actually provide?

Function block diagram (FBD) programming is a common language for PLCs following the IEC 61131 standard. What is FBD, and…

Function block diagram (FBD) programming is a common language for PLCs following the IEC 61131 standard. What is FBD, and how does it differ from the familiar ladder logic programs?

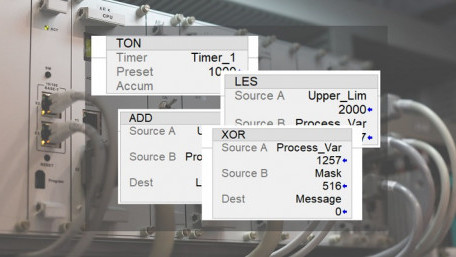

Programmable Logic Controllers (PLCs) are designed as an endlessly-looping program, examining all lines of code as…

Programmable Logic Controllers (PLCs) are designed as an endlessly-looping program, examining all lines of code as rapidly as possible. Following are a few critical tips for when programmers only need to run a series of single operations at startup.

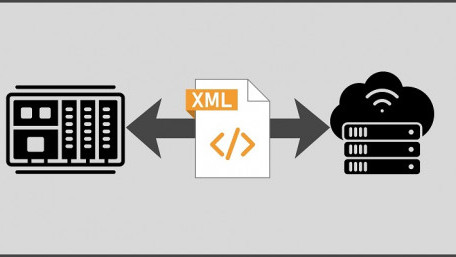

The basic component of data exchange between devices, machines, and embedded systems serves as a hallmark foundation in…

The basic component of data exchange between devices, machines, and embedded systems serves as a hallmark foundation in every organization’s Industry 4.0 implementation process.

A walkthrough and discussion of a simple web-based HMI solution that could modernize your current HMI technology stack.…

A walkthrough and discussion of a simple web-based HMI solution that could modernize your current HMI technology stack. The first step in the process involves sending data from a device to a server.

Control.com’s Director of Engineering got to explore IO-Link sensors and what he found might surprise you! Although…

Control.com’s Director of Engineering got to explore IO-Link sensors and what he found might surprise you! Although still considered an “emerging” technology, it’s clear IO-Link technology boasts several bonafide benefits over traditional sensors.

Understanding the building blocks of s-domain analysis and magnitude response theory can go a long way in helping…

Understanding the building blocks of s-domain analysis and magnitude response theory can go a long way in helping engineers predict how and why some system design choices are made over others.

Refining and integrating a front-end HMI application to an API middle layer with real-time data display and historian…

Refining and integrating a front-end HMI application to an API middle layer with real-time data display and historian capabilities for short-term data visualization.

Learn the first steps in focusing on the integration of a front-end HMI application to an API middle layer.

Learn the first steps in focusing on the integration of a front-end HMI application to an API middle layer.

The middle layer, or API layer of a custom-built HMI project involves a server that can submit or receive data to and…

The middle layer, or API layer of a custom-built HMI project involves a server that can submit or receive data to and from a device, either to provide the user interface or interact with the machine.

Many articles address the wiring and implementation of analog control signals, but where are they used, and what might…

Many articles address the wiring and implementation of analog control signals, but where are they used, and what might make them a better (or perhaps worse) decision than digital input/output devices?

Wireless technology is typically slower to adoption for industrial automation, but what wireless advancements are shaping…

Wireless technology is typically slower to adoption for industrial automation, but what wireless advancements are shaping the current and future landscape of the automated factory floor?