The supply chain is a vast network, from raw materials to components and finished goods. Learn what types of AI algorithms are employed to predict disruptions…

The supply chain is a vast network, from raw materials to components and finished goods. Learn what types of AI algorithms are employed to predict disruptions and enhance optimization.

Learn best practices for storing both pre-processed and raw high-frequency vibration sensor data to maximize efficiency…

Learn best practices for storing both pre-processed and raw high-frequency vibration sensor data to maximize efficiency and accuracy for applications like predictive maintenance.

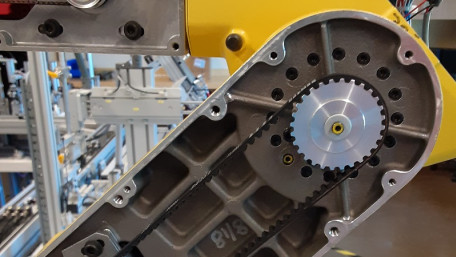

Across every make and model of articulated robot, certain maintenance procedures must be followed as motion occurs.…

Across every make and model of articulated robot, certain maintenance procedures must be followed as motion occurs. Failure to do so can often result in warnings, alarms, and even failure.

No doubt you have heard all about the use cases of AI and predictive maintenance. Learn about the algorithms that are…

No doubt you have heard all about the use cases of AI and predictive maintenance. Learn about the algorithms that are actually used to provide analysis and insights based on industrial data sets.

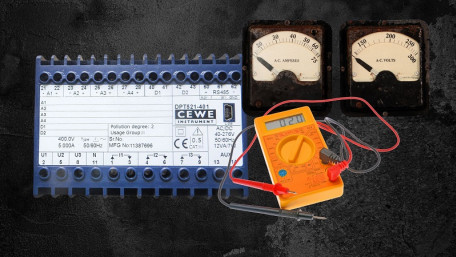

In any process industry, transducers are the basic instrumentation unit for continuous monitoring of system variables…

In any process industry, transducers are the basic instrumentation unit for continuous monitoring of system variables that provide inputs for control system algorithms and outputs.

Predicting when maintenance should occur isn’t simply a matter of getting on board with the latest trend, it can save…

Predicting when maintenance should occur isn’t simply a matter of getting on board with the latest trend, it can save many thousands of dollars in lost downtime and unnecessary parts and labor.

While mathematical expressions are important in any programming language, the topic of math functions addresses not just…

While mathematical expressions are important in any programming language, the topic of math functions addresses not just the algorithms themselves, but the design of custom functions within Python.

Learn how to use ‘for loops’ in Python to create complex, iterable tasks such as modifying lists, combining lists…

Learn how to use ‘for loops’ in Python to create complex, iterable tasks such as modifying lists, combining lists into dictionaries, or iterating over a dictionary.

We’ll start exploring loops with the ‘while’ loop in this tutorial. Loops are critical in all programming…

We’ll start exploring loops with the ‘while’ loop in this tutorial. Loops are critical in all programming languages, especially in the control world, where loops form the basis of PLC functionality.

The next part of our Python learning journey will touch upon control flow, critical to implementing logic in programs.…

The next part of our Python learning journey will touch upon control flow, critical to implementing logic in programs. The concept is broad and the first topic to cover will be if/elif statements.

Wrapping up the data structures portion of our journey are sets. This is the least frequently used data structure, but…

Wrapping up the data structures portion of our journey are sets. This is the least frequently used data structure, but don’t write off the set just yet. Its efficiency and simplicity may provide value in manufacturing data processing.

As we approach the conclusion of Python data structures, we’ll examine the tuple. Used less frequently than lists and…

As we approach the conclusion of Python data structures, we’ll examine the tuple. Used less frequently than lists and dictionaries, tuples do serve some handy use cases where immutability is a critical requirement.

Both lists and dictionaries can retain structured data in Python. The dictionary is unique in that it stores individual…

Both lists and dictionaries can retain structured data in Python. The dictionary is unique in that it stores individual entries with human-readable logical names rather than index numbers.

An introduction to the popular Python language and how to take the first step in learning programming. In this article,…

An introduction to the popular Python language and how to take the first step in learning programming. In this article, learn how to obtain the proper IDE and executable for your OS.

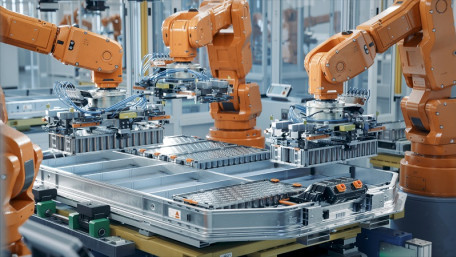

There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But…

There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But where do you start, and how do you even pick a project for automation?

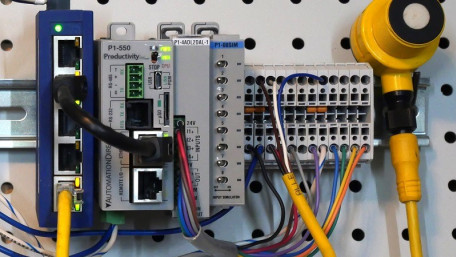

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite…

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite software. Wiring, configuring I/O, and programming will be a part of this tutorial.

Learn how to measure temperature using an RTD and a temperature transmitter to convert resistance into common analog…

Learn how to measure temperature using an RTD and a temperature transmitter to convert resistance into common analog voltage or current values for process control.

Shifting from manual code backup processes to more modern, automated solutions can provide more benefits to…

Shifting from manual code backup processes to more modern, automated solutions can provide more benefits to manufacturers, far above simply the time saved compared to manual techniques.

Electrical and mechanical measurements are often labeled with "RMS" and "True RMS." Aside from the simple math…

Electrical and mechanical measurements are often labeled with "RMS" and "True RMS." Aside from the simple math definitions we learned in electronics class, why is this distinction actually important?

In order to trace control system problems to the core, the ability to read and interpret various resources, from…

In order to trace control system problems to the core, the ability to read and interpret various resources, from facility-level diagrams to machine-level wiring layouts, is critical.