No more IIoT buzzwords! This article aims to walk through an implementation of MQTT using the paho-mqtt library using nothing more than your local machine and…

No more IIoT buzzwords! This article aims to walk through an implementation of MQTT using the paho-mqtt library using nothing more than your local machine and some simple Python programming.

Analytics from data algorithms can predict machine failures and provide diagnostics—but what should we measure? Then,…

Analytics from data algorithms can predict machine failures and provide diagnostics—but what should we measure? Then, once the information has been collected, what trends might point to problems?

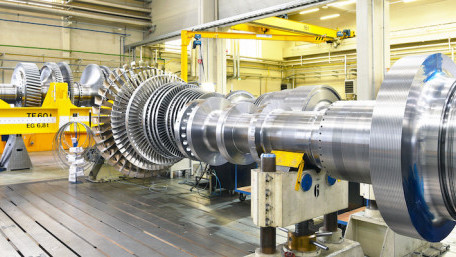

Turbine ratcheting helps prevent damage by regulating a turbine's uniform warm-up and cool-down. In this article, we will…

Turbine ratcheting helps prevent damage by regulating a turbine's uniform warm-up and cool-down. In this article, we will discuss the principles and challenges behind this process.

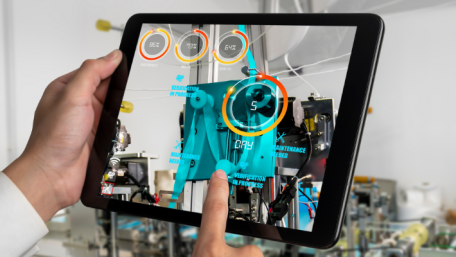

As data becomes available, maintenance can shift from being done on a rigid schedule to a more cost-effective plan of…

As data becomes available, maintenance can shift from being done on a rigid schedule to a more cost-effective plan of fixing as required, even turning attention to the root cause of maintenance woes.

IIoT is a daunting topic due to ambiguous interactions of hardware and software. This article outlines the basic steps to…

IIoT is a daunting topic due to ambiguous interactions of hardware and software. This article outlines the basic steps to use an MQTT broker to collect the number of cycles from a pneumatic cylinder for PM software.

To know if predictive maintenance is the right strategy, it might help to first recognize if it isn’t. Here are some…

To know if predictive maintenance is the right strategy, it might help to first recognize if it isn’t. Here are some indicators that your organization should improve before implementing predictive maintenance.

We are taught that parallel circuits maintain equal voltage across all branch resistors, equally sharing the source…

We are taught that parallel circuits maintain equal voltage across all branch resistors, equally sharing the source voltage. But reality is often far from ideal, and individual devices certainly impact the rest of the circuit.

We know that servo motors are found inside machines that rely on precise motion with feedback to verify proper operation,…

We know that servo motors are found inside machines that rely on precise motion with feedback to verify proper operation, but how do they work, and what makes them different from any other kind of motor?

No matter how robust an automated control system might be, physical damage is a reality that plagues all machines. Thanks…

No matter how robust an automated control system might be, physical damage is a reality that plagues all machines. Thanks to new breakthrough materials, some failures may be prevented—or even reversed.

Servers are vital to the flow of information in and around organizations, acting as a hub for information transfer and…

Servers are vital to the flow of information in and around organizations, acting as a hub for information transfer and storage. Learn about the role of servers in industry and the potential challenges that come with maintaining them.

Learn about proportional gain and proportional band, two key proportional control concepts, to better understand the most…

Learn about proportional gain and proportional band, two key proportional control concepts, to better understand the most popular control system method in industrial automation.

We'll run through the eight basic steps for implementing a predictive maintenance strategy in your business to improve…

We'll run through the eight basic steps for implementing a predictive maintenance strategy in your business to improve critical asset availability, reduced maintenance costs, and enhanced revenues over time.

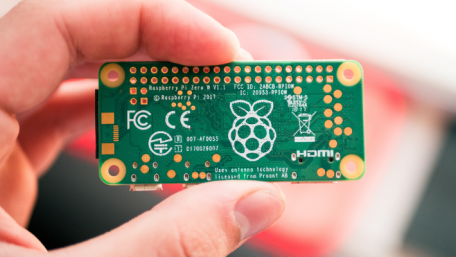

Though not a direct replacement for PLCs, Raspberry Pi has the potential to be used in industrial automation applications…

Though not a direct replacement for PLCs, Raspberry Pi has the potential to be used in industrial automation applications for prototyping, embedded systems, and as a low-cost process controller.

By shaping new concepts and business models, the IIoT is bringing more efficiency and capacity to automated systems. Take…

By shaping new concepts and business models, the IIoT is bringing more efficiency and capacity to automated systems. Take a look at some of the ways the IIoT is revolutionizing the manufacturing and automation sectors.

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial…

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial manufacturing by remotely identifying problems with electric motors and generators.

Hello acoustics, my old friend. I've come to monitor you again. Because a worn-out bearing softly creeping, slowly got…

Hello acoustics, my old friend. I've come to monitor you again. Because a worn-out bearing softly creeping, slowly got worse while I was sleeping. And the vibration that was planted in my brain still remains… Within the sound of Maintenance

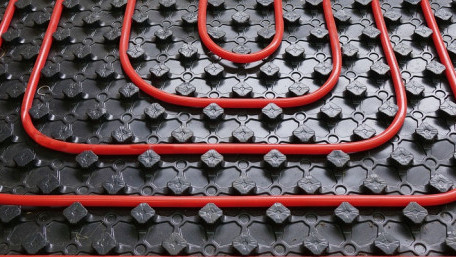

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal?…

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal? Some systems use simple open/close valves, but others require far more precision.

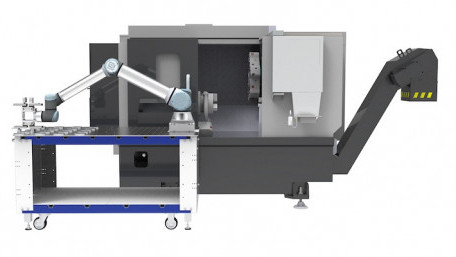

Our own Control Automation engineering staff had the opportunity to visit VersaBuilt, a CNC robotic integration shop…

Our own Control Automation engineering staff had the opportunity to visit VersaBuilt, a CNC robotic integration shop offering an application system from the Universal Robots UR+ series.

The objective of predictive maintenance is to foresee potential machine failure with the help of machine learning…

The objective of predictive maintenance is to foresee potential machine failure with the help of machine learning algorithms provided with vast quantities of data.

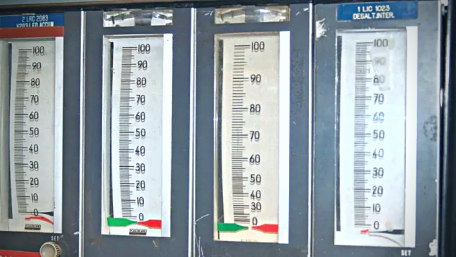

The fourth pillar of effective statistical process control (SPC) is the use of designed experiments used to learn as much…

The fourth pillar of effective statistical process control (SPC) is the use of designed experiments used to learn as much as possible from a limited number of experiments, yet remain statistically relevant enough to be useful.