Learn about the history, framework, and current uses of the Open Platform Communications United Architecture (OPC UA) communication protocol in industrial automation.

Learn about the history, framework, and current uses of the Open Platform Communications United Architecture (OPC UA) communication protocol in industrial automation.

Human-machine interfaces, or HMIs, provide visual process data and allow access to process parameters and diagnostics…

Human-machine interfaces, or HMIs, provide visual process data and allow access to process parameters and diagnostics information. What’s inside these touchscreen displays, and how do they actually work?

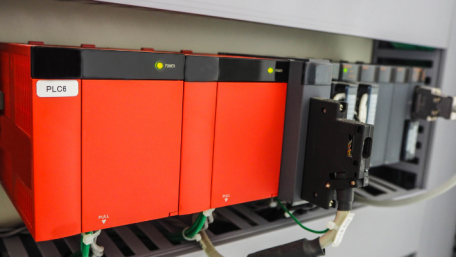

There are three main types of numeric values that must be handled by a PLC: boolean, integers, and floating point. These…

There are three main types of numeric values that must be handled by a PLC: boolean, integers, and floating point. These last floating-point values can create the most confusion for programmers and technicians.

Ambient light, reflection, and transparent objects can all cause difficulties during machine vision applications. Learn…

Ambient light, reflection, and transparent objects can all cause difficulties during machine vision applications. Learn about these issues and some potential solutions to better ensure safety and quality.

Sequential Function Chart (SFC) is a graphical programming language among the languages identified by IEC 61131-3…

Sequential Function Chart (SFC) is a graphical programming language among the languages identified by IEC 61131-3 programming languages and standard for PLC programming using ladder logic.

The ability to utilize an array effectively is a fundamental skill in becoming a PLC programmer, but it can also be very…

The ability to utilize an array effectively is a fundamental skill in becoming a PLC programmer, but it can also be very complex and difficult to master. Let’s do a run-down of arrays and some of their complexities!

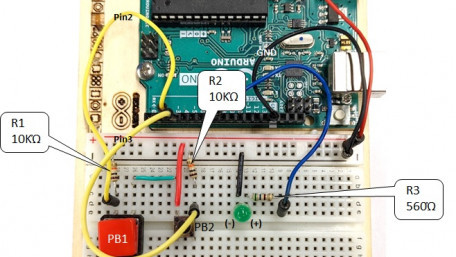

Build a low-cost PLC using the Arduino Uno and the open-source industrial controls software, OpenPLC, to learn how to…

Build a low-cost PLC using the Arduino Uno and the open-source industrial controls software, OpenPLC, to learn how to program with ladder logic, beginning with your first OpenPLC project: Hello World.

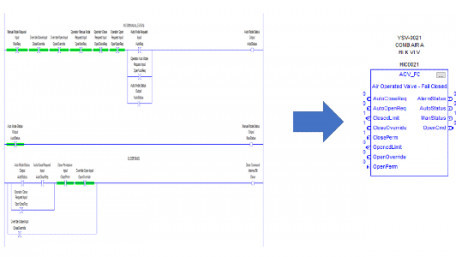

Learn how to take advantage of the powerful AOI feature that comes standard in Allen-Bradley / Rockwell PLCs using…

Learn how to take advantage of the powerful AOI feature that comes standard in Allen-Bradley / Rockwell PLCs using RSLogix 5000 and Studio 5000 Software.

Ladder logic and structured text language are fairly common yet visually different. How do you choose the best PLC…

Ladder logic and structured text language are fairly common yet visually different. How do you choose the best PLC language for your automation application?

Arduinos have been a staple in the community of makers, students, and project innovators for many…

Arduinos have been a staple in the community of makers, students, and project innovators for many years. For many using Arduino’s IDE, there can be difficulties in translating between PLC ladder rungs and text programming.

Moving data is a critical function of PLCs. In this article, we’ll talk about Move, Masked Move, Copy File, and…

Moving data is a critical function of PLCs. In this article, we’ll talk about Move, Masked Move, Copy File, and Synchronous Copy File and show how they can be used to move individual pieces of data and entire arrays.

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells,…

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells, which are often simpler and less expensive than industrial robot work cells.

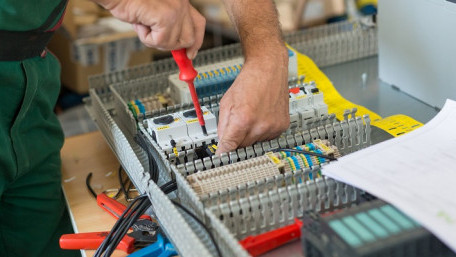

Learn about power side and ground side switching and how designing these circuits to have predictable failures from the…

Learn about power side and ground side switching and how designing these circuits to have predictable failures from the beginning helps in system maintenance and troubleshooting.

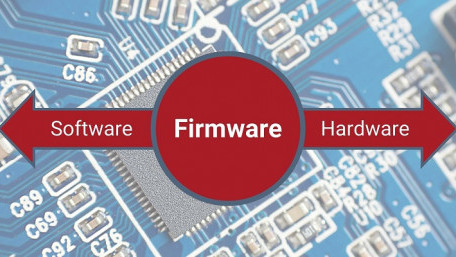

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and…

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and registers, and even the communication of network signals. This is the job of firmware.

We will show you how to recognize, utilize, and efficiently operate your comparison instructions in…

We will show you how to recognize, utilize, and efficiently operate your comparison instructions in Rockwell Automation’s Studio 5000 and Automation Direct’s Productivity Suite to make your program flow smoothly.

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean,…

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean, well-organized, and easy-to-use code that allows you and other users to troubleshoot your programs.

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial…

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial manufacturing by remotely identifying problems with electric motors and generators.

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and…

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and Automation Direct Productivity Suite.

Software obsolescence poses a threat in industrial automation equal to hardware obsolescence and should not be…

Software obsolescence poses a threat in industrial automation equal to hardware obsolescence and should not be overlooked. Many PLC OEMs offer tools to migrate upgraded software projects to the newest controller revisions.

Configuring analog signals into usable digital quantities is accomplished by scaling function inside the PLC, which,…

Configuring analog signals into usable digital quantities is accomplished by scaling function inside the PLC, which, along with analog signal wiring, is important to understand.