Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational…

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational insights about machine performance statistics.

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common…

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common instruction is the one-shot, capable of harnessing the incredible processing speeds in a CPU.

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as…

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as retentive timers and define the inputs and outputs required to properly use them.

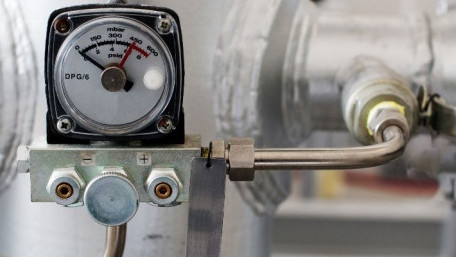

Scaling values has a wide range of applications and helps to match output values to their real-world applications. Most…

Scaling values has a wide range of applications and helps to match output values to their real-world applications. Most scaling is linear, but many of these real-world changes are not quite so simple.

Hello acoustics, my old friend. I've come to monitor you again. Because a worn-out bearing softly creeping, slowly got…

Hello acoustics, my old friend. I've come to monitor you again. Because a worn-out bearing softly creeping, slowly got worse while I was sleeping. And the vibration that was planted in my brain still remains… Within the sound of Maintenance

Our Control Automation engineering staff got the chance to visit a commercial farm in North Dakota and learn the hardware…

Our Control Automation engineering staff got the chance to visit a commercial farm in North Dakota and learn the hardware and software making these huge automated tractors ready for high-tech ‘field’ work.

In this first of an upcoming series, we investigate Siemens as a major PLC manufacturer, learning about the hardware,…

In this first of an upcoming series, we investigate Siemens as a major PLC manufacturer, learning about the hardware, software, and key applications of each product lineup.

Epson robot programming bears similarities to other industry-standard brands, but contains many unique features,…

Epson robot programming bears similarities to other industry-standard brands, but contains many unique features, including the ability to run background programs alongside the main function.

Advanced features such as programmable limits, diagnostics, and remote configuration are available with IO-Link devices.…

Advanced features such as programmable limits, diagnostics, and remote configuration are available with IO-Link devices. Learn how to connect an example IO-Link block into an actual PLC project.

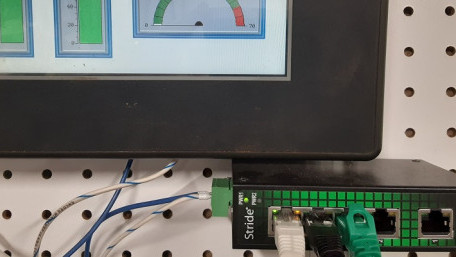

With the increasing appearance of “web-based” HMIs, we investigate these devices, learn how they differ from the…

With the increasing appearance of “web-based” HMIs, we investigate these devices, learn how they differ from the graphical HMIs, and see implications for our modern control system architecture.

A common staple in the pharmaceutical industry, Epson robots come in a variety of models, programmed with the SPEL+…

A common staple in the pharmaceutical industry, Epson robots come in a variety of models, programmed with the SPEL+ language. Learn the unique traits of the language before diving deeper into a programming example.

Before digital control systems, responses were fairly slow. Push a button, and a motor contactor engaged. These days, the…

Before digital control systems, responses were fairly slow. Push a button, and a motor contactor engaged. These days, the speed of computers introduces some new challenges but brings solutions as well.

Modbus is a communication protocol stemming from the early days of Modicon PLCs, but is still common today. These two…

Modbus is a communication protocol stemming from the early days of Modicon PLCs, but is still common today. These two example implementations of Modbus transactions will get you started.

The objective of predictive maintenance is to foresee potential machine failure with the help of machine learning…

The objective of predictive maintenance is to foresee potential machine failure with the help of machine learning algorithms provided with vast quantities of data.

Failures of I/O systems are a common source of headache for control engineers. Troubleshooting those devices that have…

Failures of I/O systems are a common source of headache for control engineers. Troubleshooting those devices that have polarized connections (source vs sink, and NPN vs PNP) is a technique worth refining.

We've read about the capabilities of collaborative robots, but often, one question still remains - how do you program a…

We've read about the capabilities of collaborative robots, but often, one question still remains - how do you program a cobot? Last week, I got a chance to get my hands on a cobot for the first time.

Product lifecycle management (PLM) and industrial automation are growing closer together. This article explores recent…

Product lifecycle management (PLM) and industrial automation are growing closer together. This article explores recent trends and application examples of this software in industry.

The fourth pillar of effective statistical process control (SPC) is the use of designed experiments used to learn as much…

The fourth pillar of effective statistical process control (SPC) is the use of designed experiments used to learn as much as possible from a limited number of experiments, yet remain statistically relevant enough to be useful.

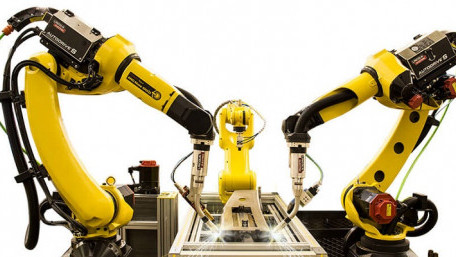

FANUC robots, as with most other brands, are designed to be used in a wide variety of applications. Learn the common…

FANUC robots, as with most other brands, are designed to be used in a wide variety of applications. Learn the common programming concepts and features along with an example of a motion program.

Statistical process control (SPC) allows for continual improvement process (CIP), a method of optimizing a process driven…

Statistical process control (SPC) allows for continual improvement process (CIP), a method of optimizing a process driven by data and statistical methods.