It's important to keep your system up and running without regular intervention. While every system requires maintenance, never overlook the critical importance…

It's important to keep your system up and running without regular intervention. While every system requires maintenance, never overlook the critical importance of tools and training for the operators.

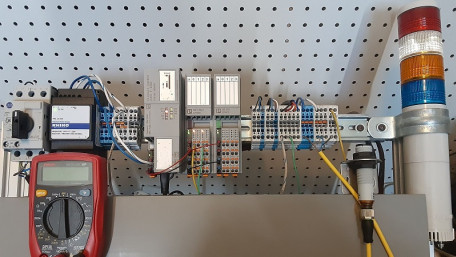

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design…

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design simple data processing programs with the PLCnext Engineer IDE.

Wrapping up the data structures portion of our journey are sets. This is the least frequently used data structure, but…

Wrapping up the data structures portion of our journey are sets. This is the least frequently used data structure, but don’t write off the set just yet. Its efficiency and simplicity may provide value in manufacturing data processing.

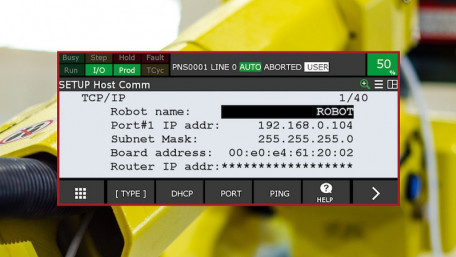

Every method of connecting to an industrial device—USB, serial, or Ethernet—poses challenges. For Ethernet, we often…

Every method of connecting to an industrial device—USB, serial, or Ethernet—poses challenges. For Ethernet, we often must adjust the IP address of our PC, not only the device itself.

As we approach the conclusion of Python data structures, we’ll examine the tuple. Used less frequently than lists and…

As we approach the conclusion of Python data structures, we’ll examine the tuple. Used less frequently than lists and dictionaries, tuples do serve some handy use cases where immutability is a critical requirement.

When setting up a system for the first time, the process can seem complex and daunting. However, there are tools…

When setting up a system for the first time, the process can seem complex and daunting. However, there are tools available to make the job much easier before commissioning.

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a…

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a PLC environment for plant control as well as an OS for more advanced IIoT projects.

Both lists and dictionaries can retain structured data in Python. The dictionary is unique in that it stores individual…

Both lists and dictionaries can retain structured data in Python. The dictionary is unique in that it stores individual entries with human-readable logical names rather than index numbers.

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic…

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic functions, and when might they be preferred over normal PLC ladder logic?

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary…

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary I/O, communication protocols, and processor necessary for controlling your system?

Learn how to write a ladder logic program to assign a string value to a data register and share that register with any…

Learn how to write a ladder logic program to assign a string value to a data register and share that register with any HMI compatible with Mitsubishi’s MELSEC PLC series.

This section will dive into the world of data structures used within the Python programming environment, starting with…

This section will dive into the world of data structures used within the Python programming environment, starting with one of the more commonly used structures called ‘lists.’

Sensors with timer functions advance modern automation systems, enhancing the precision and flexibility of in-process…

Sensors with timer functions advance modern automation systems, enhancing the precision and flexibility of in-process controls to ease the strict requirement for an external, clock-based logic CPU.

Although DC motor technology has a strong legacy, control strategies vary from simple to complex. Designs must consider…

Although DC motor technology has a strong legacy, control strategies vary from simple to complex. Designs must consider not just the motor, but also the electrical supply and the environment.

This article will focus on the basic building blocks of the Python programming language that are core to interacting with…

This article will focus on the basic building blocks of the Python programming language that are core to interacting with programs, including strings, integers, floats, and booleans.

Learn how to use GT Designer 3 to create an interactive control system on Mitsubishi HMIs. With practical examples of…

Learn how to use GT Designer 3 to create an interactive control system on Mitsubishi HMIs. With practical examples of simple on/off bits, gain some understanding of HMI designing and programming.

An introduction to the popular Python language and how to take the first step in learning programming. In this article,…

An introduction to the popular Python language and how to take the first step in learning programming. In this article, learn how to obtain the proper IDE and executable for your OS.

Learn how to set up Ethernet/IP communications, including steps for both the FANUC controller and the Studio 5000…

Learn how to set up Ethernet/IP communications, including steps for both the FANUC controller and the Studio 5000 environment for a Rockwell PLC.

Detecting objects is the first field-level task that must be considered before any feedback-based control can happen.…

Detecting objects is the first field-level task that must be considered before any feedback-based control can happen. Choosing from among the nearly unlimited proximity sensors can be challenging!

There are multiple methods for mapping inputs and outputs to an industrial robot. In this article, we cover two of the…

There are multiple methods for mapping inputs and outputs to an industrial robot. In this article, we cover two of the most popular methods: letting the robot or the PLC control the I/O signals.