Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic functions, and when might they be…

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic functions, and when might they be preferred over normal PLC ladder logic?

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary…

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary I/O, communication protocols, and processor necessary for controlling your system?

Learn how to write a ladder logic program to assign a string value to a data register and share that register with any…

Learn how to write a ladder logic program to assign a string value to a data register and share that register with any HMI compatible with Mitsubishi’s MELSEC PLC series.

This section will dive into the world of data structures used within the Python programming environment, starting with…

This section will dive into the world of data structures used within the Python programming environment, starting with one of the more commonly used structures called ‘lists.’

Sensors with timer functions advance modern automation systems, enhancing the precision and flexibility of in-process…

Sensors with timer functions advance modern automation systems, enhancing the precision and flexibility of in-process controls to ease the strict requirement for an external, clock-based logic CPU.

Learn how to use GT Designer 3 to create an interactive control system on Mitsubishi HMIs. With practical examples of…

Learn how to use GT Designer 3 to create an interactive control system on Mitsubishi HMIs. With practical examples of simple on/off bits, gain some understanding of HMI designing and programming.

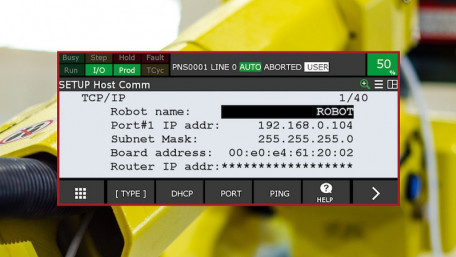

Learn how to set up Ethernet/IP communications, including steps for both the FANUC controller and the Studio 5000…

Learn how to set up Ethernet/IP communications, including steps for both the FANUC controller and the Studio 5000 environment for a Rockwell PLC.

Detecting objects is the first field-level task that must be considered before any feedback-based control can happen.…

Detecting objects is the first field-level task that must be considered before any feedback-based control can happen. Choosing from among the nearly unlimited proximity sensors can be challenging!

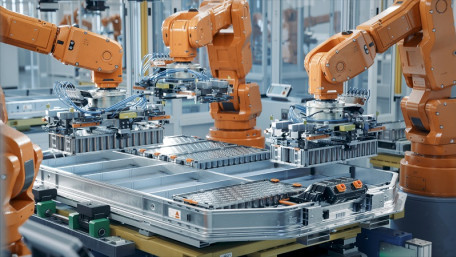

There are multiple methods for mapping inputs and outputs to an industrial robot. In this article, we cover two of the…

There are multiple methods for mapping inputs and outputs to an industrial robot. In this article, we cover two of the most popular methods: letting the robot or the PLC control the I/O signals.

Learn how to use DirectSOFT6 to program discrete I/O functions in a Koyo DirectLOGIC PLC. Although these PLCs are older,…

Learn how to use DirectSOFT6 to program discrete I/O functions in a Koyo DirectLOGIC PLC. Although these PLCs are older, they are found in many existing automation installations.

Parameters control the operation and command sources for VFDs. The PowerFlex series from Rockwell Automation is no…

Parameters control the operation and command sources for VFDs. The PowerFlex series from Rockwell Automation is no exception. Learn how to adjust the parameters for networking and IP configuration.

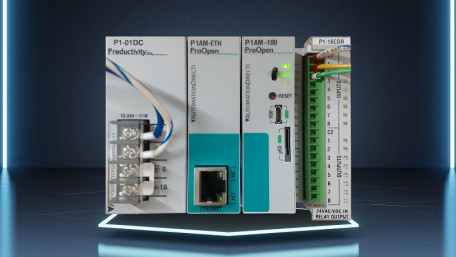

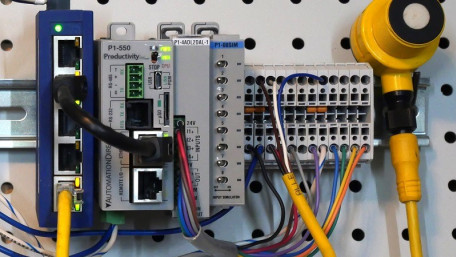

Having separately covered Arduino’s microcontroller platforms and AutomationDirect Productivity PLCs, it’s time to…

Having separately covered Arduino’s microcontroller platforms and AutomationDirect Productivity PLCs, it’s time to take the wheel of the ProOpen, a PLC that combines modularity with C++ programming.

Expanding motor drives with I/O is a cost-effective way of increasing local control without burdening the control system.…

Expanding motor drives with I/O is a cost-effective way of increasing local control without burdening the control system. Control Technique’s new SI-I/O 24 Plus expands I/O right on the drive unit.

There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But…

There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But where do you start, and how do you even pick a project for automation?

Controlling an industrial robot can be done through the use of well-crafted signal handshakes. Follow along as we dive…

Controlling an industrial robot can be done through the use of well-crafted signal handshakes. Follow along as we dive into several robot-to-PLC communication strategies.

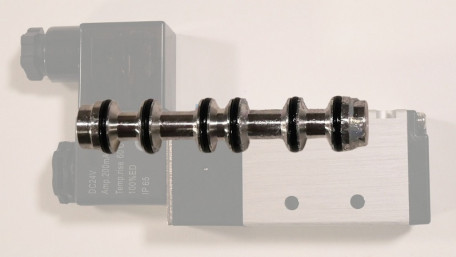

Fluid control valves rely on the opening and closing of internal passageways to direct the flow of power. But what do…

Fluid control valves rely on the opening and closing of internal passageways to direct the flow of power. But what do they look like inside, and how do these ‘valve spools’ actually work?

There are a few options when it comes to tracking part data throughout a process or assembly of a machine. Follow along…

There are a few options when it comes to tracking part data throughout a process or assembly of a machine. Follow along as we explain just a few of the more common methods.

Recently, the Control.com engineering team had the opportunity to visit the R&D demo lab facility for the robotics…

Recently, the Control.com engineering team had the opportunity to visit the R&D demo lab facility for the robotics division of Epson, located in Los Alamitos, CA. Come learn how the magic happens!

I/O mapping is the process of converting raw input and output data into specific tags, but how can we find a method for…

I/O mapping is the process of converting raw input and output data into specific tags, but how can we find a method for mapping I/O that is both efficient and scalable?

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite…

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite software. Wiring, configuring I/O, and programming will be a part of this tutorial.