Relay and other coil devices pose a few confusing questions: How can the relay still work if you connect a DC supply in reverse? How can an alternating voltage…

Relay and other coil devices pose a few confusing questions: How can the relay still work if you connect a DC supply in reverse? How can an alternating voltage attract and hold the load consistently?

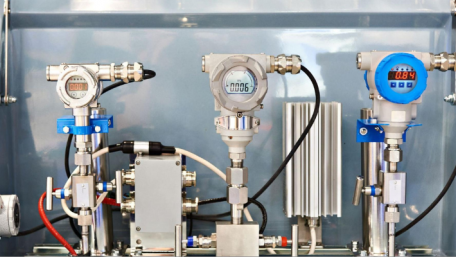

Industrial analog sensor devices primarily use 0-10 volt or 4-20 milliamp. For those mA signals, learn the reasons for…

Industrial analog sensor devices primarily use 0-10 volt or 4-20 milliamp. For those mA signals, learn the reasons for why the lower and upper limit standards were determined as 4 mA and 20 mA.

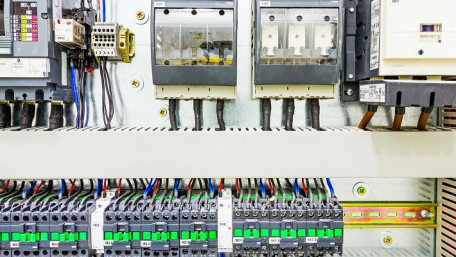

Industrial control panels are at the heart of control systems. Learn about the standards and regulations that dictate…

Industrial control panels are at the heart of control systems. Learn about the standards and regulations that dictate industrial control panel design for safety and efficiency, including NFPA 70, UL 60947-4-1, and NFPA 79.

Humidity control is vital in many industrial applications. We'll take a look at nine different humidity measurement…

Humidity control is vital in many industrial applications. We'll take a look at nine different humidity measurement technologies, how they are used, and discuss the difference between relative humidity and dew point.

Ambient light, reflection, and transparent objects can all cause difficulties during machine vision applications. Learn…

Ambient light, reflection, and transparent objects can all cause difficulties during machine vision applications. Learn about these issues and some potential solutions to better ensure safety and quality.

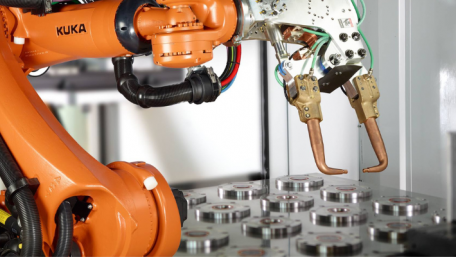

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited…

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited possibilities. Learn about the five main methods of how EOATs are powered and the sensors that they use.

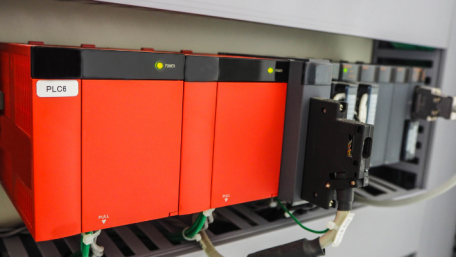

While B&R PLC controllers are quite different from typical PLCs, Automation Studio offers tools and features that make…

While B&R PLC controllers are quite different from typical PLCs, Automation Studio offers tools and features that make programming them less intensive. In this article, we’ll discuss how to program B&R PLCs with Automation Studio.

The ability to utilize an array effectively is a fundamental skill in becoming a PLC programmer, but it can also be very…

The ability to utilize an array effectively is a fundamental skill in becoming a PLC programmer, but it can also be very complex and difficult to master. Let’s do a run-down of arrays and some of their complexities!

Blockchain is a secure and decentralized system of immutable database records that can be useful in manufacturing, such…

Blockchain is a secure and decentralized system of immutable database records that can be useful in manufacturing, such as with product traceability and logging network activity from IoT industrial devices.

As the IIoT continues to grow in the industrial sector, businesses face a number of obstacles to integrating its…

As the IIoT continues to grow in the industrial sector, businesses face a number of obstacles to integrating its solutions. Learn about these challenges as well as some potential solutions.

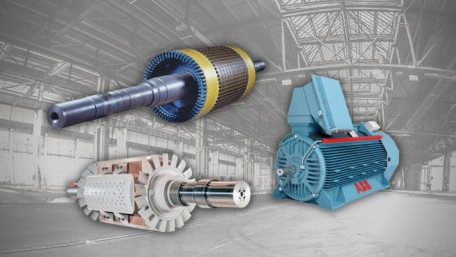

In this article, we will take a look at the differences between synchronous and induction motors, as well as the two…

In this article, we will take a look at the differences between synchronous and induction motors, as well as the two types of induction motors: squirrel cage and wound rotor.

Remote locations are notoriously difficult to supply power, yet they are the exact locations where many data points must…

Remote locations are notoriously difficult to supply power, yet they are the exact locations where many data points must be collected. How can IoT devices be designed to conserve power to last for months or even years?

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers…

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers are necessary to implement IIoT in an industrial setting to benefit varying processes.

Robots are no longer unanimously just "robots"—there are specific tasks and functionality of each kind. Learn about the…

Robots are no longer unanimously just "robots"—there are specific tasks and functionality of each kind. Learn about the technology differences between fixed-location robots and mobile robots and why no one robot is like another.

B&R is a control system manufacturer less heard of than some of its bigger competitors, Rockwell and Siemens, however…

B&R is a control system manufacturer less heard of than some of its bigger competitors, Rockwell and Siemens, however their PLCs, lineup of motors, and product offerings with Automation Studio make B&R a leader in industrial innovation.

Software distribution models have historically been on premises, however, as industry has become more digital,…

Software distribution models have historically been on premises, however, as industry has become more digital, cloud-based solutions have become increasingly popular, including SaaS and its variants, IaaS and PaaS.

When selecting the right module for the right load, be sure to understand how the load resistance will affect the voltage…

When selecting the right module for the right load, be sure to understand how the load resistance will affect the voltage and current of the output module terminals.

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These…

Over the last decade, cloud service providers have improved technology, particularly data security and integrity. These remain the top concern of many manufacturing businesses, but as improvements are rolled out, more and more companies are adopting cloud solutions.

Mobile robot work cells can move between workstations and tend to where demand is highest. These self-contained work…

Mobile robot work cells can move between workstations and tend to where demand is highest. These self-contained work cells offer more flexibility for manufacturers than industrial and collaborative robot cells we have previously talked about.

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime.…

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime. Learn about the ways extreme heat can damage automated equipment and systems.