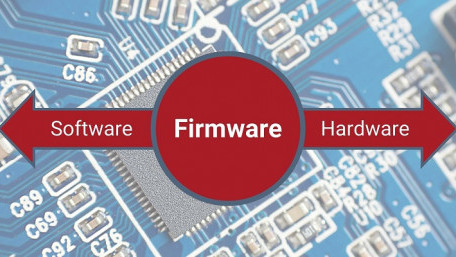

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and registers, and even the communication of…

Inside a controller, code is interpreted into the binary signals that influence input and output signals, flags and registers, and even the communication of network signals. This is the job of firmware.

Fuses and breakers are some of the most common safeguards to prevent electrical shock and fires. Learn about these two…

Fuses and breakers are some of the most common safeguards to prevent electrical shock and fires. Learn about these two pieces of industrial equipment and the difference between slow blow and quick blow responses.

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with…

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with perhaps the most basic: how do you program industrial robots?

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their…

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their advantages and disadvantages when it comes to choosing which one to use in manufacturing.

The CTRL F3 series reviews field studies and failures in the field focused on control fails, fixes, and facts. This…

The CTRL F3 series reviews field studies and failures in the field focused on control fails, fixes, and facts. This article covers an explosion at an industrial sawmill.

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when…

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when these systems should be bonded with the earth ground of the AC line voltage supply.

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In…

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In this article, we will look at PLC programming of fieldbus manifolds highlighting Festo's CPX layout.

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and…

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and Automation Direct Productivity Suite.

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement…

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational insights about machine performance statistics.

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common…

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common instruction is the one-shot, capable of harnessing the incredible processing speeds in a CPU.

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and…

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and unavailable, and the lack of an upgrade plan can turn a simple failure into a catastrophe.

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the…

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the world of control systems. Learn how the hardware platforms have evolved into the familiar modern configurations.

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as…

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as retentive timers and define the inputs and outputs required to properly use them.

Power supplies tend to get a reputation as one of the most important power considerations of a DC control circuit - but…

Power supplies tend to get a reputation as one of the most important power considerations of a DC control circuit - but we can’t ignore other key players: power filters, converters, and backup power modules.

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal?…

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal? Some systems use simple open/close valves, but others require far more precision.

Allen Bradley’s Data Highway Plus (DH+) networking ability is still found commonly in interfaces with legacy equipment.…

Allen Bradley’s Data Highway Plus (DH+) networking ability is still found commonly in interfaces with legacy equipment. Understanding this network structure can bridge the gap between old and new systems.

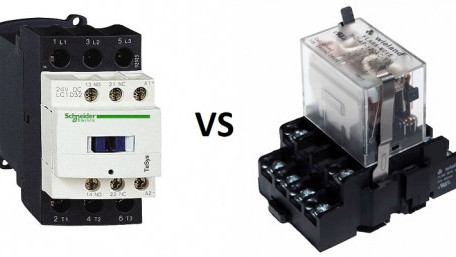

Although the are similarities in operating theory, relays and contactors are used in industrial circuits for different…

Although the are similarities in operating theory, relays and contactors are used in industrial circuits for different specific applications, and should not be used interchangeably.

In honor of May the 4th, Star Wars Day, we compare the sources and applications of the two most common force-delivery…

In honor of May the 4th, Star Wars Day, we compare the sources and applications of the two most common force-delivery systems - mechanical and hydraulic.

Two common methods exist for driving induction motors with VFDs - linear scalar control, which is often labeled as V/f,…

Two common methods exist for driving induction motors with VFDs - linear scalar control, which is often labeled as V/f, and vector, or field-oriented control, which can be a bit more complex to understand.

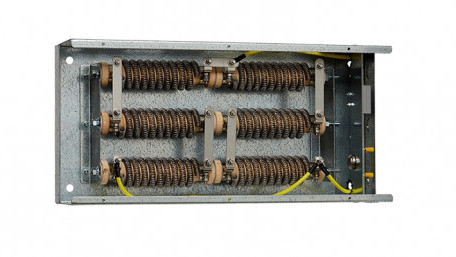

Large DC and AC motor drives often provide terminals for installing a braking resistor. What are these resistors, and how…

Large DC and AC motor drives often provide terminals for installing a braking resistor. What are these resistors, and how do they slow down a machine? What hazards and cautions must be considered?