Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their advantages and disadvantages when it comes to…

Centralized control systems are often seen as outdated compared to decentralized systems; however, both have their advantages and disadvantages when it comes to choosing which one to use in manufacturing.

The CTRL F3 series reviews field studies and failures in the field focused on control fails, fixes, and facts. This…

The CTRL F3 series reviews field studies and failures in the field focused on control fails, fixes, and facts. This article covers an explosion at an industrial sawmill.

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when…

DC voltage systems exist to provide controllers and field devices with stable power, but it is not always clear when these systems should be bonded with the earth ground of the AC line voltage supply.

Singularity in robotics can be problematic for programmers and manufacturers alike. We will investigate the cause of…

Singularity in robotics can be problematic for programmers and manufacturers alike. We will investigate the cause of singularities and how prevention can be considered in the design of a robot cell.

We will show you how to recognize, utilize, and efficiently operate your comparison instructions in…

We will show you how to recognize, utilize, and efficiently operate your comparison instructions in Rockwell Automation’s Studio 5000 and Automation Direct’s Productivity Suite to make your program flow smoothly.

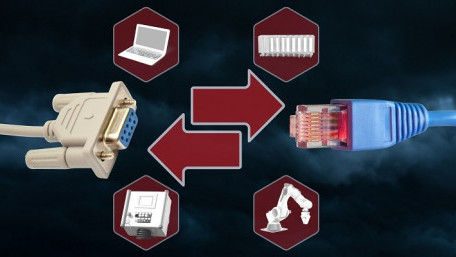

One common challenge when working with legacy control systems is establishing communication with old devices that use old…

One common challenge when working with legacy control systems is establishing communication with old devices that use old protocols like RS232 and RS485. Learn about the importance of converting from serial to Ethernet.

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In…

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In this article, we will look at PLC programming of fieldbus manifolds highlighting Festo's CPX layout.

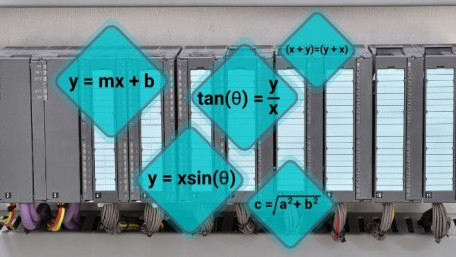

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean,…

We will show you how to use the basic trigonometry functions to build ladder logic in a PLC, allowing for a clean, well-organized, and easy-to-use code that allows you and other users to troubleshoot your programs.

Industrial robots are a valuable investment because of their speed and accuracy. However, failing to establish the tool…

Industrial robots are a valuable investment because of their speed and accuracy. However, failing to establish the tool center point (TCP) can decrease the accuracy, effectiveness, and ROI for a robot workcell.

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial…

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial manufacturing by remotely identifying problems with electric motors and generators.

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and…

We will show you how to use common math functions from two popular PLC programs—Rockwell Automation's Studio 5000 and Automation Direct Productivity Suite.

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement…

Counting up and down are commonly required functions in PLC lagger logic programs for tracking inventories, placement patterns, and gaining informational insights about machine performance statistics.

Designing an obsolescence mitigation plan to detect and solve mitigation risks before they occur is key to avoiding…

Designing an obsolescence mitigation plan to detect and solve mitigation risks before they occur is key to avoiding costly downtime and a potential catastrophe in control environments.

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common…

Many PLC commands are well-known to programmers, including contacts, coils, timers, and counters. But a less-common instruction is the one-shot, capable of harnessing the incredible processing speeds in a CPU.

Control engineering is integrally woven together with electricity and electrical circuits. Even so, sometimes the most…

Control engineering is integrally woven together with electricity and electrical circuits. Even so, sometimes the most basic scenarios become misunderstood through lack of training or experience.

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and…

One of the most considerable risks in aging control environments is that eventually, spare parts become obsolete and unavailable, and the lack of an upgrade plan can turn a simple failure into a catastrophe.

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the…

Credited with coining the name ‘PLC’, Allen-Bradley and parent company Rockwell Automation are major players in the world of control systems. Learn how the hardware platforms have evolved into the familiar modern configurations.

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as…

The timer is a fundamental function of ladder logic programming. In this article, we discuss on- and off-delay as well as retentive timers and define the inputs and outputs required to properly use them.

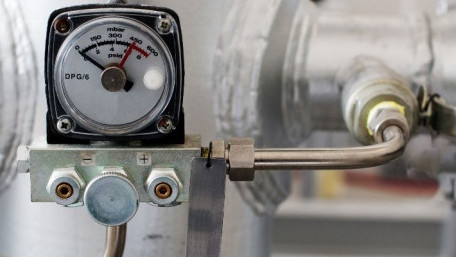

Scaling values has a wide range of applications and helps to match output values to their real-world applications. Most…

Scaling values has a wide range of applications and helps to match output values to their real-world applications. Most scaling is linear, but many of these real-world changes are not quite so simple.

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission.…

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission. But when we say ‘easy’, how easy can it really be to commission robotic tools?