Closed-loop motor control is a control system used to regulate the output of a motor. Learn about the four common types of closed-loop motor control systems to…

Closed-loop motor control is a control system used to regulate the output of a motor. Learn about the four common types of closed-loop motor control systems to understand each one’s inner-workings and applications.

Many control product manufacturers offer these downloadable ‘EDS files’ for peripheral equipment, but what exactly is…

Many control product manufacturers offer these downloadable ‘EDS files’ for peripheral equipment, but what exactly is an EDS, and how can they aid in the development of a project?

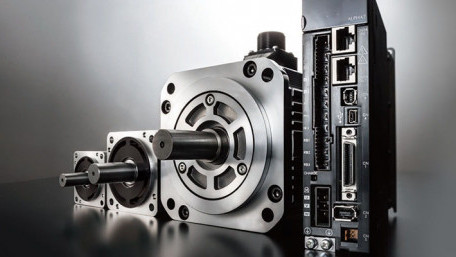

We know that servo motors are found inside machines that rely on precise motion with feedback to verify proper operation,…

We know that servo motors are found inside machines that rely on precise motion with feedback to verify proper operation, but how do they work, and what makes them different from any other kind of motor?

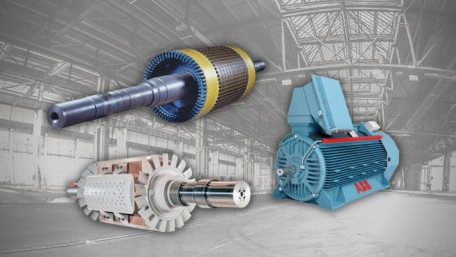

Coil, field winding, rotor, stator, eddy current… When it comes to motors, there are numerous terms that describe the…

Coil, field winding, rotor, stator, eddy current… When it comes to motors, there are numerous terms that describe the theory of operation, but what is inside a 3-phase motor? Take a look, and learn how they work.

When accurate positioning and speed control is needed, most engineers turn to servo motors or stepper motors, but what is…

When accurate positioning and speed control is needed, most engineers turn to servo motors or stepper motors, but what is the difference between the two, and which is the right choice?

Variable frequency drive units can be found inside tons of control cabinets, but what happens if you disassemble one to…

Variable frequency drive units can be found inside tons of control cabinets, but what happens if you disassemble one to see what’s inside and how it works? We did just that. The results might surprise you.

Connecting a new motor without knowing the phase rotation of the electrical supply can cause damage to expensive…

Connecting a new motor without knowing the phase rotation of the electrical supply can cause damage to expensive equipment. By using a 3-phase rotation meter, you can save yourself time and money.

With precise control abilities to manage speed, torque, and direction, variable frequency drives remain one of the most…

With precise control abilities to manage speed, torque, and direction, variable frequency drives remain one of the most common methods of driving 3-phase industrial motors. Below, we introduce a few leading VFD manufacturers.

Safety is one of the most critical aspects of machine design. Today, with network connections between different machines…

Safety is one of the most critical aspects of machine design. Today, with network connections between different machines and control centers, safety signals must be shared logically and reliably across networks.

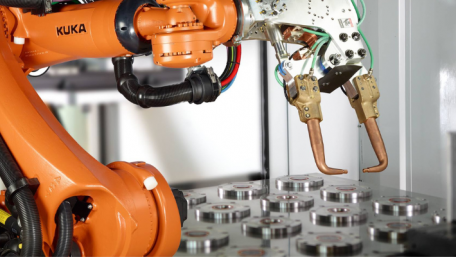

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited…

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited possibilities. Learn about the five main methods of how EOATs are powered and the sensors that they use.

In this article, we will take a look at the differences between synchronous and induction motors, as well as the two…

In this article, we will take a look at the differences between synchronous and induction motors, as well as the two types of induction motors: squirrel cage and wound rotor.

B&R is a control system manufacturer less heard of than some of its bigger competitors, Rockwell and Siemens, however…

B&R is a control system manufacturer less heard of than some of its bigger competitors, Rockwell and Siemens, however their PLCs, lineup of motors, and product offerings with Automation Studio make B&R a leader in industrial innovation.

Any machine can become a source of elevated temperature, even under regular operation. We cannot assume that temperature…

Any machine can become a source of elevated temperature, even under regular operation. We cannot assume that temperature problems occur only based on climate conditions, and mitigation steps must be employed.

The diverse power terms in electrical generation systems include active, reactive, and apparent power, all of which lead…

The diverse power terms in electrical generation systems include active, reactive, and apparent power, all of which lead to the introduction of ‘power factor’ effectiveness in an AC circuit.

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime.…

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime. Learn about the ways extreme heat can damage automated equipment and systems.

The CTRL F3 series reviews field studies and failures in the field focused on control fails, fixes, and facts. This…

The CTRL F3 series reviews field studies and failures in the field focused on control fails, fixes, and facts. This article covers an explosion at an industrial sawmill.

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial…

Electrical signal analysis has come to the forefront of predictive maintenance, helping to reduce downtime in industrial manufacturing by remotely identifying problems with electric motors and generators.

Even with the most reliable networks, network outages are inevitable for a host of reasons, and managing these outages in…

Even with the most reliable networks, network outages are inevitable for a host of reasons, and managing these outages in VFD systems becomes critically important.

In honor of May the 4th, Star Wars Day, we compare the sources and applications of the two most common force-delivery…

In honor of May the 4th, Star Wars Day, we compare the sources and applications of the two most common force-delivery systems - mechanical and hydraulic.

Our Control Automation engineering staff got the chance to visit a commercial farm in North Dakota and learn the hardware…

Our Control Automation engineering staff got the chance to visit a commercial farm in North Dakota and learn the hardware and software making these huge automated tractors ready for high-tech ‘field’ work.