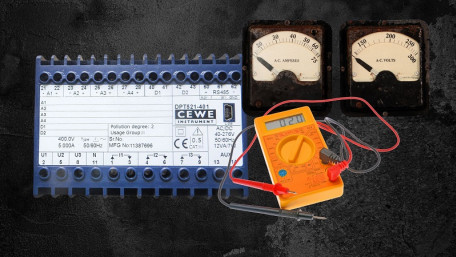

In any process industry, transducers are the basic instrumentation unit for continuous monitoring of system variables that provide inputs for control system…

In any process industry, transducers are the basic instrumentation unit for continuous monitoring of system variables that provide inputs for control system algorithms and outputs.

Logic is critical for industrial control, and it usually looks like ladders, function blocks, or structured text. I/O…

Logic is critical for industrial control, and it usually looks like ladders, function blocks, or structured text. I/O controllers are designed to automate simple logic tasks and data functions.

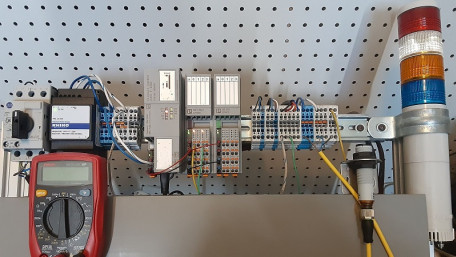

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design…

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design simple data processing programs with the PLCnext Engineer IDE.

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a…

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a PLC environment for plant control as well as an OS for more advanced IIoT projects.

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic…

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic functions, and when might they be preferred over normal PLC ladder logic?

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary…

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary I/O, communication protocols, and processor necessary for controlling your system?

Expanding motor drives with I/O is a cost-effective way of increasing local control without burdening the control system.…

Expanding motor drives with I/O is a cost-effective way of increasing local control without burdening the control system. Control Technique’s new SI-I/O 24 Plus expands I/O right on the drive unit.

There are a few options when it comes to tracking part data throughout a process or assembly of a machine. Follow along…

There are a few options when it comes to tracking part data throughout a process or assembly of a machine. Follow along as we explain just a few of the more common methods.

I/O mapping is the process of converting raw input and output data into specific tags, but how can we find a method for…

I/O mapping is the process of converting raw input and output data into specific tags, but how can we find a method for mapping I/O that is both efficient and scalable?

Controlling and optimizing plant processes is the goal of most control systems. It can be a challenge to distinguish…

Controlling and optimizing plant processes is the goal of most control systems. It can be a challenge to distinguish between different types of control: a DCS or a high-level SCADA system?

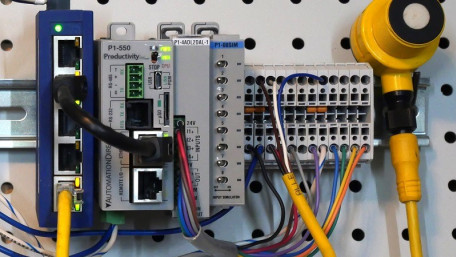

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite…

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite software. Wiring, configuring I/O, and programming will be a part of this tutorial.

Learn how to measure temperature using an RTD and a temperature transmitter to convert resistance into common analog…

Learn how to measure temperature using an RTD and a temperature transmitter to convert resistance into common analog voltage or current values for process control.

Creating custom alarm systems can be complicated and overwhelming, but they can also be very beneficial for equipment…

Creating custom alarm systems can be complicated and overwhelming, but they can also be very beneficial for equipment builders and integrators. Follow along as we build a custom alarm handling system.

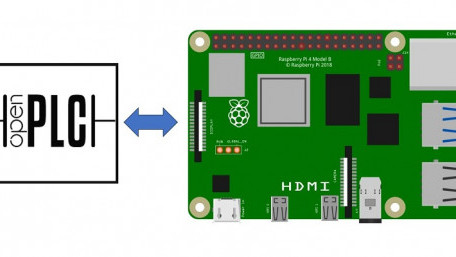

Using a Raspberry Pi and the OpenPLC software platform, create a simple PLC that can be programmed in ladder diagrams…

Using a Raspberry Pi and the OpenPLC software platform, create a simple PLC that can be programmed in ladder diagrams with remote access and I/O monitoring dashboards.

Have you ever heard of a relay? Of course you have. There are many different kinds, plus hundreds of different trade…

Have you ever heard of a relay? Of course you have. There are many different kinds, plus hundreds of different trade lingo names. What are some of the most common, and how do we use them?

Storing data long-term for recording and reporting purposes is the job of the utility data warehouse, quite different…

Storing data long-term for recording and reporting purposes is the job of the utility data warehouse, quite different from data-collection processes that optimize systems and predict failures.

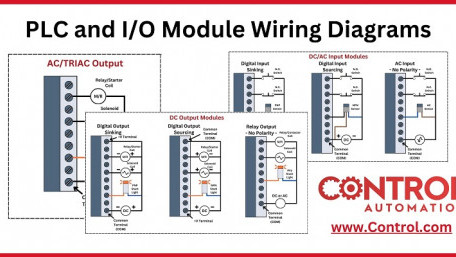

A complete diagram for wiring nearly any kind of discrete I/O module, including digital, AC, or relay, including both…

A complete diagram for wiring nearly any kind of discrete I/O module, including digital, AC, or relay, including both sourcing and sinking varieties.

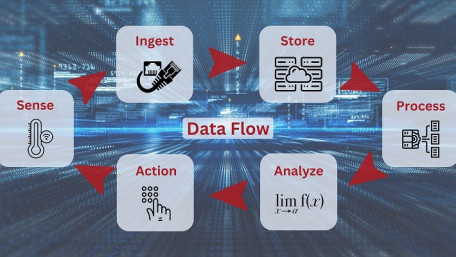

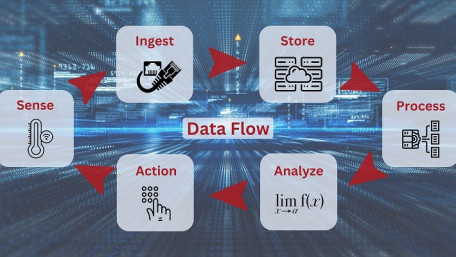

We conclude the data flow project with the step of developing a business intelligence dashboard to present machine data,…

We conclude the data flow project with the step of developing a business intelligence dashboard to present machine data, at a reliable schedule, to a leadership or maintenance team.

It’s important to consider your PLC tag naming convention when using different styles. Learn when and why you might…

It’s important to consider your PLC tag naming convention when using different styles. Learn when and why you might even use more than one, depending on the circumstances and scope of your project.

We begin to wrap up our data flow project with an introduction to visual-based (GUI) tools and dashboards to present the…

We begin to wrap up our data flow project with an introduction to visual-based (GUI) tools and dashboards to present the data ingested from the Google Sheets fault data source.