The next part of our Python learning journey will touch upon control flow, critical to implementing logic in programs. The concept is broad and the first topic…

The next part of our Python learning journey will touch upon control flow, critical to implementing logic in programs. The concept is broad and the first topic to cover will be if/elif statements.

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design…

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design simple data processing programs with the PLCnext Engineer IDE.

Wrapping up the data structures portion of our journey are sets. This is the least frequently used data structure, but…

Wrapping up the data structures portion of our journey are sets. This is the least frequently used data structure, but don’t write off the set just yet. Its efficiency and simplicity may provide value in manufacturing data processing.

As we approach the conclusion of Python data structures, we’ll examine the tuple. Used less frequently than lists and…

As we approach the conclusion of Python data structures, we’ll examine the tuple. Used less frequently than lists and dictionaries, tuples do serve some handy use cases where immutability is a critical requirement.

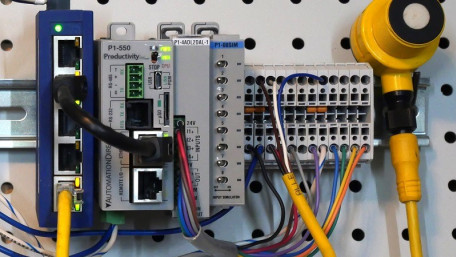

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a…

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a PLC environment for plant control as well as an OS for more advanced IIoT projects.

Both lists and dictionaries can retain structured data in Python. The dictionary is unique in that it stores individual…

Both lists and dictionaries can retain structured data in Python. The dictionary is unique in that it stores individual entries with human-readable logical names rather than index numbers.

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary…

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary I/O, communication protocols, and processor necessary for controlling your system?

This section will dive into the world of data structures used within the Python programming environment, starting with…

This section will dive into the world of data structures used within the Python programming environment, starting with one of the more commonly used structures called ‘lists.’

This article will focus on the basic building blocks of the Python programming language that are core to interacting with…

This article will focus on the basic building blocks of the Python programming language that are core to interacting with programs, including strings, integers, floats, and booleans.

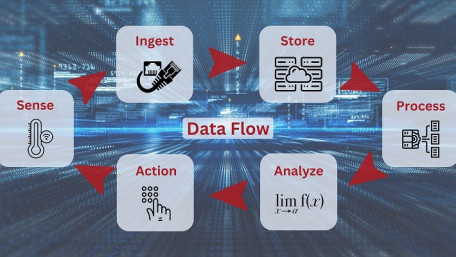

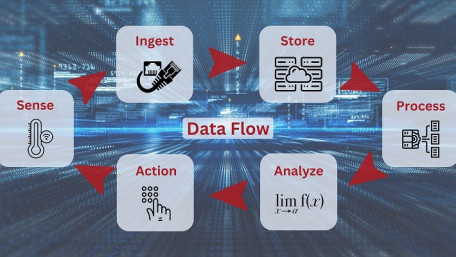

High-level IT/OT integration in a manufacturing environment involves skills in networking communication and field…

High-level IT/OT integration in a manufacturing environment involves skills in networking communication and field equipment. This example involves automating remote connections between computers.

An introduction to the popular Python language and how to take the first step in learning programming. In this article,…

An introduction to the popular Python language and how to take the first step in learning programming. In this article, learn how to obtain the proper IDE and executable for your OS.

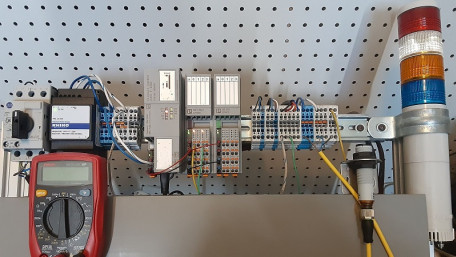

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite…

Learn how to use analog I/O devices with AutomationDirect’s Productivity series of PLCs and Productivity Suite software. Wiring, configuring I/O, and programming will be a part of this tutorial.

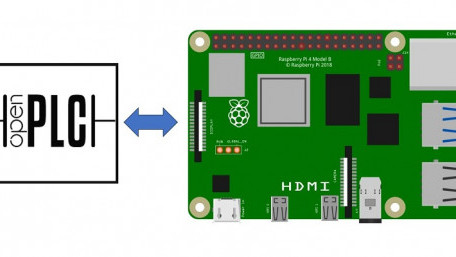

Using a Raspberry Pi and the OpenPLC software platform, create a simple PLC that can be programmed in ladder diagrams…

Using a Raspberry Pi and the OpenPLC software platform, create a simple PLC that can be programmed in ladder diagrams with remote access and I/O monitoring dashboards.

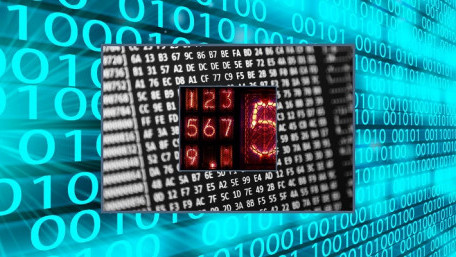

Converting different numbering systems is quite common in PLCs and structured text codes. Why? Because people read…

Converting different numbering systems is quite common in PLCs and structured text codes. Why? Because people read decimals. Computers read binary. Processors read sets of bits. Not so simple.

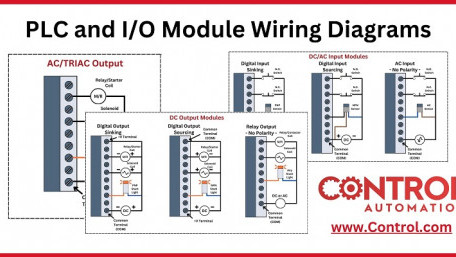

A complete diagram for wiring nearly any kind of discrete I/O module, including digital, AC, or relay, including both…

A complete diagram for wiring nearly any kind of discrete I/O module, including digital, AC, or relay, including both sourcing and sinking varieties.

It’s important to consider your PLC tag naming convention when using different styles. Learn when and why you might…

It’s important to consider your PLC tag naming convention when using different styles. Learn when and why you might even use more than one, depending on the circumstances and scope of your project.

We begin to wrap up our data flow project with an introduction to visual-based (GUI) tools and dashboards to present the…

We begin to wrap up our data flow project with an introduction to visual-based (GUI) tools and dashboards to present the data ingested from the Google Sheets fault data source.

In this article, we will explore the inbound integration to the mage.ai pipeline, connecting to the spreadsheet data…

In this article, we will explore the inbound integration to the mage.ai pipeline, connecting to the spreadsheet data source using the Google Sheets API through a JSON credentials file.

When inputs or outputs stop working, the equipment fails to respond and money starts slipping away. Dive into the concept…

When inputs or outputs stop working, the equipment fails to respond and money starts slipping away. Dive into the concept of troubleshooting I/O without ever opening the PLC software.

Rebooting industrial controllers and computers incurs costs, not only from the downtime but also from cascading effects…

Rebooting industrial controllers and computers incurs costs, not only from the downtime but also from cascading effects of communication with up/downstream controllers. How can this downtime be managed?