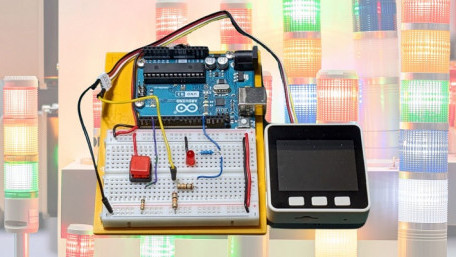

A flasher can easily be implemented using interlocking timers in a PLC environment on an Arduino Uno using OpenPLC, UiFlow Blockly Code, and a programmable…

A flasher can easily be implemented using interlocking timers in a PLC environment on an Arduino Uno using OpenPLC, UiFlow Blockly Code, and a programmable HMI-based LCD unit.

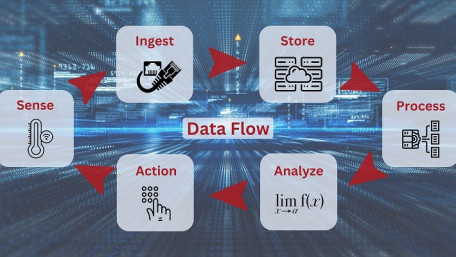

In this article, we will explore the inbound integration to the mage.ai pipeline, connecting to the spreadsheet data…

In this article, we will explore the inbound integration to the mage.ai pipeline, connecting to the spreadsheet data source using the Google Sheets API through a JSON credentials file.

When inputs or outputs stop working, the equipment fails to respond and money starts slipping away. Dive into the concept…

When inputs or outputs stop working, the equipment fails to respond and money starts slipping away. Dive into the concept of troubleshooting I/O without ever opening the PLC software.

Machine downtime can be very stressful for everybody involved. Next time you face a challenging system failure, try some…

Machine downtime can be very stressful for everybody involved. Next time you face a challenging system failure, try some of these LED troubleshooting techniques to reduce stress.

Power systems rely on meaningful data, as do most other processes. Within SCADA environments, individual data points are…

Power systems rely on meaningful data, as do most other processes. Within SCADA environments, individual data points are tracked, compared to limits, and evaluated to obtain current readings.

Rebooting industrial controllers and computers incurs costs, not only from the downtime but also from cascading effects…

Rebooting industrial controllers and computers incurs costs, not only from the downtime but also from cascading effects of communication with up/downstream controllers. How can this downtime be managed?

Innovation has a single purpose: to create better solutions, meaning more efficient output with faster development and…

Innovation has a single purpose: to create better solutions, meaning more efficient output with faster development and troubleshooting. It starts with the strategies used to program machines.

A PLC can be placed in Run or Stop, or occasionally Program mode, usually through physical or virtual methods. But what…

A PLC can be placed in Run or Stop, or occasionally Program mode, usually through physical or virtual methods. But what do these modes mean, and when should they be used?

If you’re working collaboratively with teams in a corporate industrial setting and require a version control system for…

If you’re working collaboratively with teams in a corporate industrial setting and require a version control system for critical software or documents, Git is a must-have in your skillset.

Function block diagrams can be a useful tool, but they can also add a lot of complexity. Learn about the what, when,…

Function block diagrams can be a useful tool, but they can also add a lot of complexity. Learn about the what, when, where, and why of function block diagram (FBD) programming.

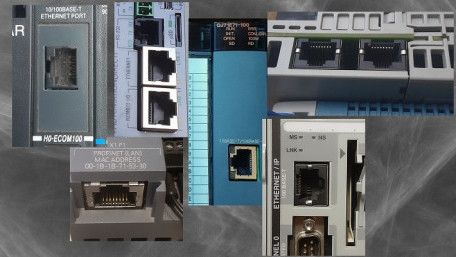

Some controllers and network devices have one port, while others have two. Why is there a difference, and what advantages…

Some controllers and network devices have one port, while others have two. Why is there a difference, and what advantages does having two network ports actually provide?

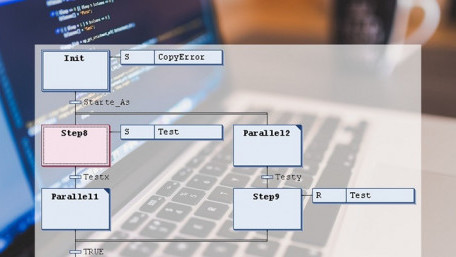

Sequential function charts (SFCs) are a great tool when processes require sequence control, but things can get…

Sequential function charts (SFCs) are a great tool when processes require sequence control, but things can get complicated fast. Here are some ways to create better SFC programs and applications.

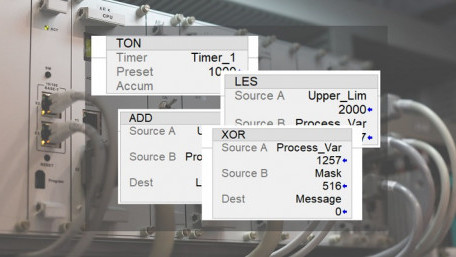

Function block diagram (FBD) programming is a common language for PLCs following the IEC 61131 standard. What is FBD, and…

Function block diagram (FBD) programming is a common language for PLCs following the IEC 61131 standard. What is FBD, and how does it differ from the familiar ladder logic programs?

Analog voltage and current are the dominating standards for industrial technology. Is one format better than the other?…

Analog voltage and current are the dominating standards for industrial technology. Is one format better than the other? And if so, why do both signal types still exist in modern systems?

Programmable Logic Controllers (PLCs) are designed as an endlessly-looping program, examining all lines of code as…

Programmable Logic Controllers (PLCs) are designed as an endlessly-looping program, examining all lines of code as rapidly as possible. Following are a few critical tips for when programmers only need to run a series of single operations at startup.

A walkthrough and discussion of a simple web-based HMI solution that could modernize your current HMI technology stack.…

A walkthrough and discussion of a simple web-based HMI solution that could modernize your current HMI technology stack. The first step in the process involves sending data from a device to a server.

Control.com’s Director of Engineering got to explore IO-Link sensors and what he found might surprise you! Although…

Control.com’s Director of Engineering got to explore IO-Link sensors and what he found might surprise you! Although still considered an “emerging” technology, it’s clear IO-Link technology boasts several bonafide benefits over traditional sensors.

From forest to felling, logging road to mill, finished lumber’s adventure on its way to market is filled with control…

From forest to felling, logging road to mill, finished lumber’s adventure on its way to market is filled with control and automation. Learn about the process from start to finish and how lumber mills ensure the world has access to high-quality lumber thanks to control technology.

Refining and integrating a front-end HMI application to an API middle layer with real-time data display and historian…

Refining and integrating a front-end HMI application to an API middle layer with real-time data display and historian capabilities for short-term data visualization.

Learn the first steps in focusing on the integration of a front-end HMI application to an API middle layer.

Learn the first steps in focusing on the integration of a front-end HMI application to an API middle layer.