Actuators are used to control the motion of manufacturing devices and raw materials. This article will compare electric actuators and several types of…

Actuators are used to control the motion of manufacturing devices and raw materials. This article will compare electric actuators and several types of fluid-power actuators.

Coil, field winding, rotor, stator, eddy current… When it comes to motors, there are numerous terms that describe the…

Coil, field winding, rotor, stator, eddy current… When it comes to motors, there are numerous terms that describe the theory of operation, but what is inside a 3-phase motor? Take a look, and learn how they work.

Air power drives a lot of modern equipment. Robot grippers, ejectors, actuators, and rotary tables are just a few of the…

Air power drives a lot of modern equipment. Robot grippers, ejectors, actuators, and rotary tables are just a few of the devices controlled by air. What’s inside those banks of solenoid valves, and how do they work?

Learn about proportional gain and proportional band, two key proportional control concepts, to better understand the most…

Learn about proportional gain and proportional band, two key proportional control concepts, to better understand the most popular control system method in industrial automation.

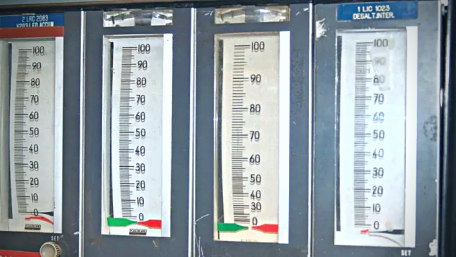

Tracking the position of a hydraulic or pneumatic cylinder is often accomplished at a basic precision level, detecting…

Tracking the position of a hydraulic or pneumatic cylinder is often accomplished at a basic precision level, detecting only end stop limits with discrete digital values… But what methods accomplish this?

Learn how one small farm in a rural community is upgrading production with advanced technology in several ways to…

Learn how one small farm in a rural community is upgrading production with advanced technology in several ways to overcome staff shortages, product demand, and regulatory compliance.

Industrial analog sensor devices primarily use 0-10 volt or 4-20 milliamp. For those mA signals, learn the reasons for…

Industrial analog sensor devices primarily use 0-10 volt or 4-20 milliamp. For those mA signals, learn the reasons for why the lower and upper limit standards were determined as 4 mA and 20 mA.

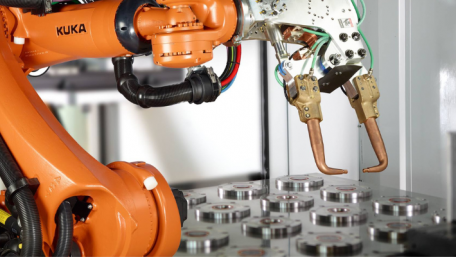

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited…

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited possibilities. Learn about the five main methods of how EOATs are powered and the sensors that they use.

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells,…

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells, which are often simpler and less expensive than industrial robot work cells.

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In…

There are many distributed fieldbus capabilities for valve manifolds that can save on network overhead and wiring. In this article, we will look at PLC programming of fieldbus manifolds highlighting Festo's CPX layout.

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission.…

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission. But when we say ‘easy’, how easy can it really be to commission robotic tools?

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal?…

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal? Some systems use simple open/close valves, but others require far more precision.

In honor of May the 4th, Star Wars Day, we compare the sources and applications of the two most common force-delivery…

In honor of May the 4th, Star Wars Day, we compare the sources and applications of the two most common force-delivery systems - mechanical and hydraulic.

Our Control Automation engineering staff got the chance to visit a commercial farm in North Dakota and learn the hardware…

Our Control Automation engineering staff got the chance to visit a commercial farm in North Dakota and learn the hardware and software making these huge automated tractors ready for high-tech ‘field’ work.

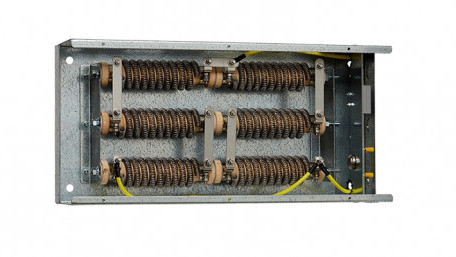

Large DC and AC motor drives often provide terminals for installing a braking resistor. What are these resistors, and how…

Large DC and AC motor drives often provide terminals for installing a braking resistor. What are these resistors, and how do they slow down a machine? What hazards and cautions must be considered?

Linear sensors use electrical means to determine their position. Common linear position sensors are resistive, inductive,…

Linear sensors use electrical means to determine their position. Common linear position sensors are resistive, inductive, capacitive, and many rely on a property called magnetostriction.

Linear position sensors are used in electrical and fluid-actuated motion devices. They allow extremely precise position,…

Linear position sensors are used in electrical and fluid-actuated motion devices. They allow extremely precise position, velocity, and acceleration control, and provide feedback to ensure product quality and tolerance compliance.

Labels are such a small detail in the world of robotics and automation, they are often given very little attention.…

Labels are such a small detail in the world of robotics and automation, they are often given very little attention. However, they play a vital role in proper system function - from installation to troubleshooting.

Moisture inside industrial pneumatic systems is a major cause for concern, and if the air is not filtered or dried…

Moisture inside industrial pneumatic systems is a major cause for concern, and if the air is not filtered or dried properly, it can lead to serious failures.

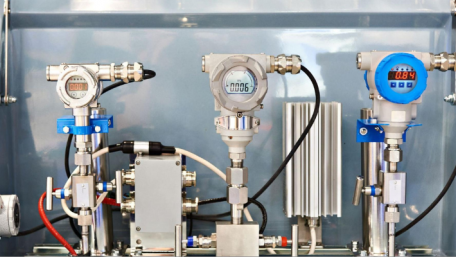

Pressure and flow rate are terms used in all areas of hydraulic and pneumatic systems. Learn the definition and science…

Pressure and flow rate are terms used in all areas of hydraulic and pneumatic systems. Learn the definition and science of these terms, and the reason they are so important within industry.