Total laboratory automation (TLA) helps in workforce utilization, reduced costs, and management of routine testing. Learn about what TLA is, its components, and…

Total laboratory automation (TLA) helps in workforce utilization, reduced costs, and management of routine testing. Learn about what TLA is, its components, and what to consider before replacing a traditional laboratory.

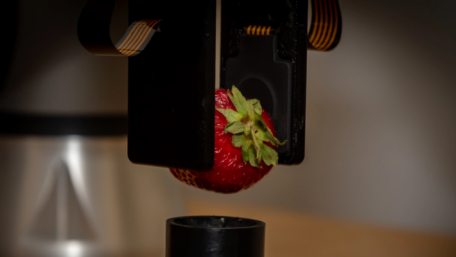

Using advanced sensing technology, robotic skin allows grippers and manipulators to “feel” and handle objects without…

Using advanced sensing technology, robotic skin allows grippers and manipulators to “feel” and handle objects without damaging them. While emulating human touch is still in its infancy, it does show promise for future applications.

When a robot crashes, it needs to be put back into position. The steps in this process depends on the end user and the…

When a robot crashes, it needs to be put back into position. The steps in this process depends on the end user and the equipment manufacturer. Understanding why the robot crashed also helps prevent future failures.

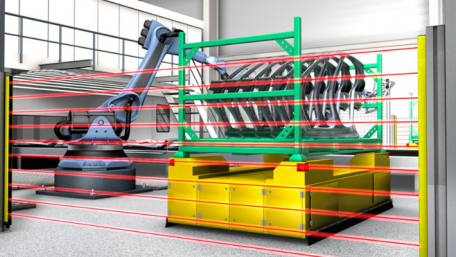

Light curtains serve as an invisible barrier, keeping workers out of harm's way and protecting machinery from damage.…

Light curtains serve as an invisible barrier, keeping workers out of harm's way and protecting machinery from damage. Learn about safety curtains, how they are installed, and their programmable functions.

Learn how one small farm in a rural community is upgrading production with advanced technology in several ways to…

Learn how one small farm in a rural community is upgrading production with advanced technology in several ways to overcome staff shortages, product demand, and regulatory compliance.

Ambient light, reflection, and transparent objects can all cause difficulties during machine vision applications. Learn…

Ambient light, reflection, and transparent objects can all cause difficulties during machine vision applications. Learn about these issues and some potential solutions to better ensure safety and quality.

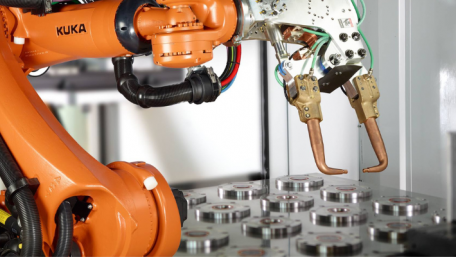

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited…

An EOAT, located at the end of an industrial or collaborative robot arm, is entirely customizable with nearly unlimited possibilities. Learn about the five main methods of how EOATs are powered and the sensors that they use.

Robots are no longer unanimously just "robots"—there are specific tasks and functionality of each kind. Learn about the…

Robots are no longer unanimously just "robots"—there are specific tasks and functionality of each kind. Learn about the technology differences between fixed-location robots and mobile robots and why no one robot is like another.

Mobile robot work cells can move between workstations and tend to where demand is highest. These self-contained work…

Mobile robot work cells can move between workstations and tend to where demand is highest. These self-contained work cells offer more flexibility for manufacturers than industrial and collaborative robot cells we have previously talked about.

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime.…

As summer heat continues to scorch the northern hemisphere, manufacturers face potential equipment damage and downtime. Learn about the ways extreme heat can damage automated equipment and systems.

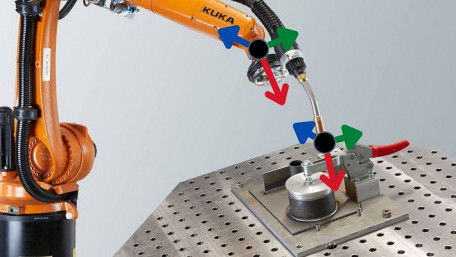

Robots must be moved using cartesian frames to coordinate motion of all the joints. Properly defining the tool center…

Robots must be moved using cartesian frames to coordinate motion of all the joints. Properly defining the tool center point greatly simplifies teaching for any type of end of arm tool (EoAT).

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells,…

Learn about the common applications, programming procedures, and safety protocols of collaborative robot work cells, which are often simpler and less expensive than industrial robot work cells.

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with…

The world of manufacturing is filled with robots, but beginners are still always faced with key questions, starting with perhaps the most basic: how do you program industrial robots?

Robot cells make for an efficient automation process, reduce labor costs, and increase worker safety. Learn about the…

Robot cells make for an efficient automation process, reduce labor costs, and increase worker safety. Learn about the common features, components, and safety requirements of industrial robot work cells.

Singularity in robotics can be problematic for programmers and manufacturers alike. We will investigate the cause of…

Singularity in robotics can be problematic for programmers and manufacturers alike. We will investigate the cause of singularities and how prevention can be considered in the design of a robot cell.

LiDAR and SLAM enable AMRs and drones to effectively navigate dynamic industrial environments. The right selection of…

LiDAR and SLAM enable AMRs and drones to effectively navigate dynamic industrial environments. The right selection of high-power laser diodes is critical for accurate performance of LiDAR/SLAM systems

Industrial robots are a valuable investment because of their speed and accuracy. However, failing to establish the tool…

Industrial robots are a valuable investment because of their speed and accuracy. However, failing to establish the tool center point (TCP) can decrease the accuracy, effectiveness, and ROI for a robot workcell.

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission.…

In the world of modern manufacturing, we want the tools to be effective, safe, and very easy to install and commission. But when we say ‘easy’, how easy can it really be to commission robotic tools?

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal?…

What if you could control the end position and the speed of a hydraulic actuator accurately with just a simple signal? Some systems use simple open/close valves, but others require far more precision.

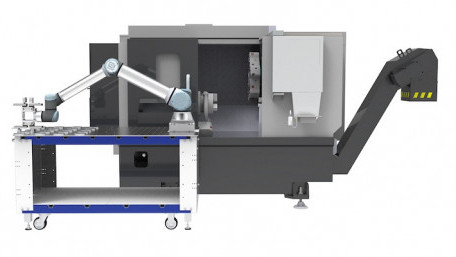

Our own Control Automation engineering staff had the opportunity to visit VersaBuilt, a CNC robotic integration shop…

Our own Control Automation engineering staff had the opportunity to visit VersaBuilt, a CNC robotic integration shop offering an application system from the Universal Robots UR+ series.