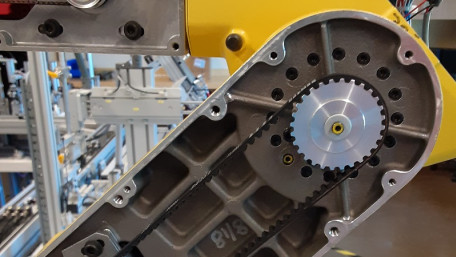

Across every make and model of articulated robot, certain maintenance procedures must be followed as motion occurs. Failure to do so can often result in…

Across every make and model of articulated robot, certain maintenance procedures must be followed as motion occurs. Failure to do so can often result in warnings, alarms, and even failure.

Join Control Automation as we visit Central CA colleges to help install robotic equipment and learn how local industries…

Join Control Automation as we visit Central CA colleges to help install robotic equipment and learn how local industries partner with schools to create exciting opportunities for students.

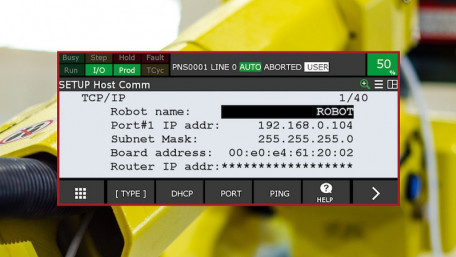

Learn how to set up Ethernet/IP communications, including steps for both the FANUC controller and the Studio 5000…

Learn how to set up Ethernet/IP communications, including steps for both the FANUC controller and the Studio 5000 environment for a Rockwell PLC.

There are multiple methods for mapping inputs and outputs to an industrial robot. In this article, we cover two of the…

There are multiple methods for mapping inputs and outputs to an industrial robot. In this article, we cover two of the most popular methods: letting the robot or the PLC control the I/O signals.

There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But…

There are a lot of companies considering in-house automation or consulting with integrators for automated systems. But where do you start, and how do you even pick a project for automation?

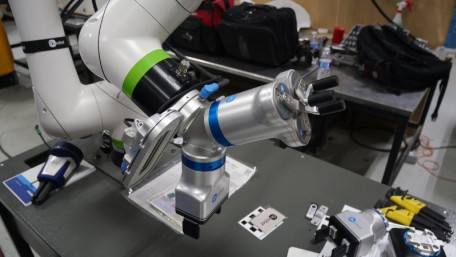

Recently, the Control.com engineering team had the opportunity to visit the R&D demo lab facility for the robotics…

Recently, the Control.com engineering team had the opportunity to visit the R&D demo lab facility for the robotics division of Epson, located in Los Alamitos, CA. Come learn how the magic happens!

In the field of robotics, designing proper end-of-arm tooling (EoAT) is a crucial step. This article includes critical…

In the field of robotics, designing proper end-of-arm tooling (EoAT) is a crucial step. This article includes critical material and inertia factors to consider when designing EoAT for 6-axis robots.

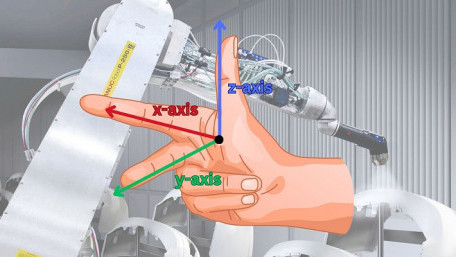

In this article, we'll explore user frames in the context of a 6-axis industrial or collaborative robot. Learn the…

In this article, we'll explore user frames in the context of a 6-axis industrial or collaborative robot. Learn the definition, practical applications, and advantages that user frames have to offer.

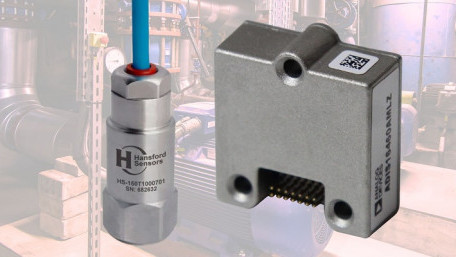

Many sensors, like prox, optical, and ultrasonic, are familiar to control engineers. More and more modern devices are…

Many sensors, like prox, optical, and ultrasonic, are familiar to control engineers. More and more modern devices are incorporating advanced motion profiles requiring motion sensing in many axes.

Learn about FANUC’s Dual Check Safety (DCS) system and the various methods, how to configure the DCS parameters, and…

Learn about FANUC’s Dual Check Safety (DCS) system and the various methods, how to configure the DCS parameters, and how to avoid and resolve issues associated with DCS positional alarms.

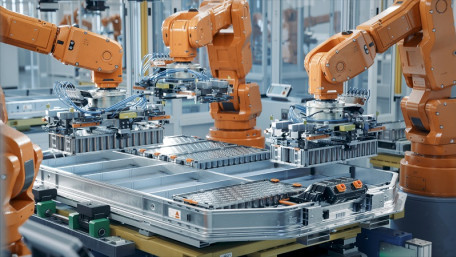

Traditionally, automation requires a sizable investment and integration risks. RaaS empowers manufacturers to let someone…

Traditionally, automation requires a sizable investment and integration risks. RaaS empowers manufacturers to let someone else adopt the risks in exchange for an hourly or monthly subscription rate.

Innovation has a single purpose: to create better solutions, meaning more efficient output with faster development and…

Innovation has a single purpose: to create better solutions, meaning more efficient output with faster development and troubleshooting. It starts with the strategies used to program machines.

Agriculture is an industry ‘ripe’ for technology, but what obstacles and opportunities lie in front of the…

Agriculture is an industry ‘ripe’ for technology, but what obstacles and opportunities lie in front of the cutting-edge innovators of the field?

Cobots have recently been hailed as one of the latest and greatest innovations in production and manufacturing…

Cobots have recently been hailed as one of the latest and greatest innovations in production and manufacturing automation. But are collaborative robots living up to their reputation? Control.com investigates the benefits and drawbacks of these versatile industrial machines.

Most commercial control technologies have fascinating histories, especially industrial robots. Here’s the story behind…

Most commercial control technologies have fascinating histories, especially industrial robots. Here’s the story behind the development of Unimate, the world’s first.

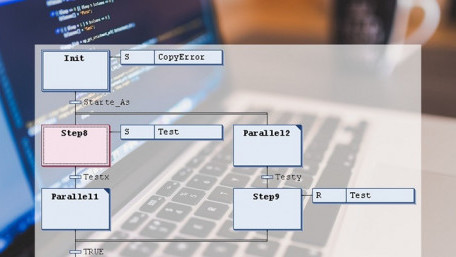

Sequential function charts (SFCs) are a great tool when processes require sequence control, but things can get…

Sequential function charts (SFCs) are a great tool when processes require sequence control, but things can get complicated fast. Here are some ways to create better SFC programs and applications.

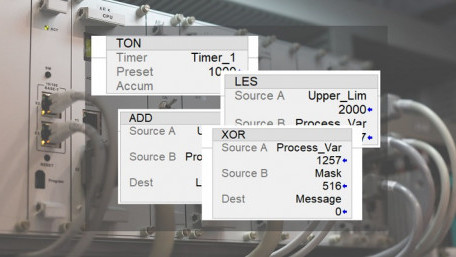

Function block diagram (FBD) programming is a common language for PLCs following the IEC 61131 standard. What is FBD, and…

Function block diagram (FBD) programming is a common language for PLCs following the IEC 61131 standard. What is FBD, and how does it differ from the familiar ladder logic programs?

Understanding the building blocks of s-domain analysis and magnitude response theory can go a long way in helping…

Understanding the building blocks of s-domain analysis and magnitude response theory can go a long way in helping engineers predict how and why some system design choices are made over others.

Some workplaces are more dangerous than others, not because of the practices, but rather the products. Where do…

Some workplaces are more dangerous than others, not because of the practices, but rather the products. Where do explosions occur, and what practices exist to reduce such risk for equipment and workforce?

Compliance and compensator devices are used in processes where variation and uncertainty are prevalent. What sorts of…

Compliance and compensator devices are used in processes where variation and uncertainty are prevalent. What sorts of compliance devices are used, and what distinct advantages are held by each?