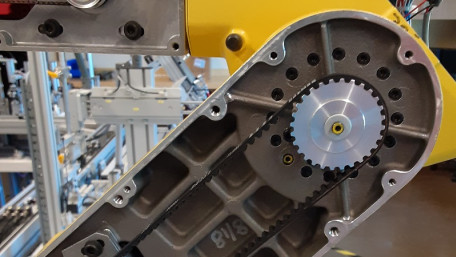

Across every make and model of articulated robot, certain maintenance procedures must be followed as motion occurs. Failure to do so can often result in…

Across every make and model of articulated robot, certain maintenance procedures must be followed as motion occurs. Failure to do so can often result in warnings, alarms, and even failure.

In the field of robotics, designing proper end-of-arm tooling (EoAT) is a crucial step. This article includes critical…

In the field of robotics, designing proper end-of-arm tooling (EoAT) is a crucial step. This article includes critical material and inertia factors to consider when designing EoAT for 6-axis robots.

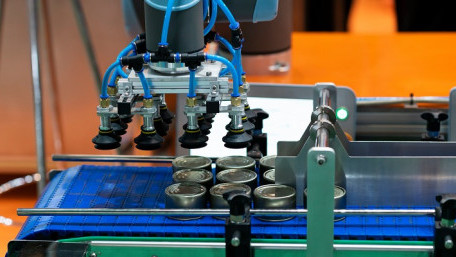

Knowing the difference between the various robotic grippers available makes selecting the most appropriate solution for…

Knowing the difference between the various robotic grippers available makes selecting the most appropriate solution for an automation project less daunting.

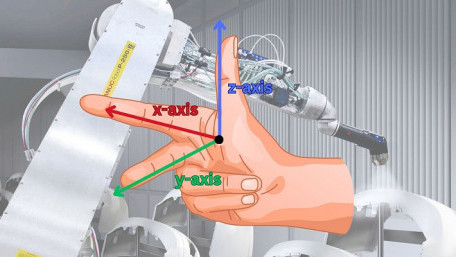

In this article, we'll explore user frames in the context of a 6-axis industrial or collaborative robot. Learn the…

In this article, we'll explore user frames in the context of a 6-axis industrial or collaborative robot. Learn the definition, practical applications, and advantages that user frames have to offer.

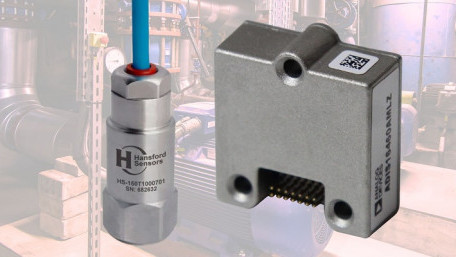

Many sensors, like prox, optical, and ultrasonic, are familiar to control engineers. More and more modern devices are…

Many sensors, like prox, optical, and ultrasonic, are familiar to control engineers. More and more modern devices are incorporating advanced motion profiles requiring motion sensing in many axes.

Learn about FANUC’s Dual Check Safety (DCS) system and the various methods, how to configure the DCS parameters, and…

Learn about FANUC’s Dual Check Safety (DCS) system and the various methods, how to configure the DCS parameters, and how to avoid and resolve issues associated with DCS positional alarms.

Traditionally, automation requires a sizable investment and integration risks. RaaS empowers manufacturers to let someone…

Traditionally, automation requires a sizable investment and integration risks. RaaS empowers manufacturers to let someone else adopt the risks in exchange for an hourly or monthly subscription rate.

Agriculture is an industry ‘ripe’ for technology, but what obstacles and opportunities lie in front of the…

Agriculture is an industry ‘ripe’ for technology, but what obstacles and opportunities lie in front of the cutting-edge innovators of the field?

Most commercial control technologies have fascinating histories, especially industrial robots. Here’s the story behind…

Most commercial control technologies have fascinating histories, especially industrial robots. Here’s the story behind the development of Unimate, the world’s first.

Programmable Logic Controllers (PLCs) are designed as an endlessly-looping program, examining all lines of code as…

Programmable Logic Controllers (PLCs) are designed as an endlessly-looping program, examining all lines of code as rapidly as possible. Following are a few critical tips for when programmers only need to run a series of single operations at startup.

Understanding the building blocks of s-domain analysis and magnitude response theory can go a long way in helping…

Understanding the building blocks of s-domain analysis and magnitude response theory can go a long way in helping engineers predict how and why some system design choices are made over others.

Some workplaces are more dangerous than others, not because of the practices, but rather the products. Where do…

Some workplaces are more dangerous than others, not because of the practices, but rather the products. Where do explosions occur, and what practices exist to reduce such risk for equipment and workforce?

Compliance and compensator devices are used in processes where variation and uncertainty are prevalent. What sorts of…

Compliance and compensator devices are used in processes where variation and uncertainty are prevalent. What sorts of compliance devices are used, and what distinct advantages are held by each?

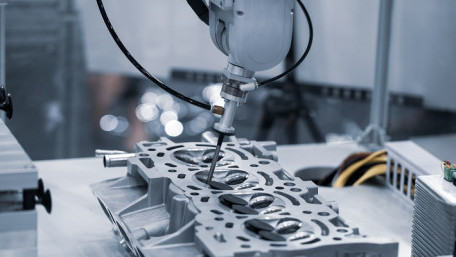

Force compensators and force compliance end effectors can expand the capabilities of traditional robotics to reach into…

Force compensators and force compliance end effectors can expand the capabilities of traditional robotics to reach into difficult processes, ranging from grinding and alignment to precision measurement.

Industrial robots are becoming safer and more economical by utilizing safety signals over Ethernet networks via CIP…

Industrial robots are becoming safer and more economical by utilizing safety signals over Ethernet networks via CIP safety technology.

Most grippers are powered by either air or electricity. Learn about the questions and factors an engineer should consider…

Most grippers are powered by either air or electricity. Learn about the questions and factors an engineer should consider to make the best decisions while selecting a gripper to use for unique applications.

Designing, installing, and maintaining control systems involves a lot of wires. Each wire has a purpose, often indicated…

Designing, installing, and maintaining control systems involves a lot of wires. Each wire has a purpose, often indicated by the color of the insulation. But what are the common colors, and what do they mean?

Total laboratory automation (TLA) helps in workforce utilization, reduced costs, and management of routine testing. Learn…

Total laboratory automation (TLA) helps in workforce utilization, reduced costs, and management of routine testing. Learn about what TLA is, its components, and what to consider before replacing a traditional laboratory.

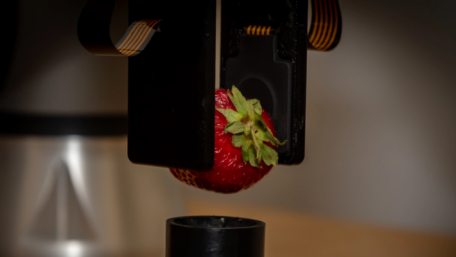

Using advanced sensing technology, robotic skin allows grippers and manipulators to “feel” and handle objects without…

Using advanced sensing technology, robotic skin allows grippers and manipulators to “feel” and handle objects without damaging them. While emulating human touch is still in its infancy, it does show promise for future applications.

When a robot crashes, it needs to be put back into position. The steps in this process depends on the end user and the…

When a robot crashes, it needs to be put back into position. The steps in this process depends on the end user and the equipment manufacturer. Understanding why the robot crashed also helps prevent future failures.