Some devices, like switches, are non-polar; you can connect them in either direction. What makes diodes so special, and how can you tell the right way from the wrong way?

Some devices, like switches, are non-polar; you can connect them in either direction. What makes diodes so special, and how can you tell the right way from the wrong way?

Ladder logic is an industrial control systems legend stemming from electrical line diagrams before the days of PLCs.…

Ladder logic is an industrial control systems legend stemming from electrical line diagrams before the days of PLCs. Although logical, they are difficult to interpret.

Several use cases for industrial AI get a lot of attention, like maintenance and process optimization. Learn how AI has…

Several use cases for industrial AI get a lot of attention, like maintenance and process optimization. Learn how AI has been used for years to ensure high-quality product monitoring and output.

Every element of your life–your food, your car, your house–everything is made with processes that use sensors. Join…

Every element of your life–your food, your car, your house–everything is made with processes that use sensors. Join us as we visit the SICK facility, where many of these sensing products are made.

Optical sensors for industrial applications are becoming increasingly intelligent. Learn how new hardware, onboard…

Optical sensors for industrial applications are becoming increasingly intelligent. Learn how new hardware, onboard software configuration, and touchscreens are unlocking new object detection capabilities.

No doubt you have heard all about the use cases of AI and predictive maintenance. Learn about the algorithms that are…

No doubt you have heard all about the use cases of AI and predictive maintenance. Learn about the algorithms that are actually used to provide analysis and insights based on industrial data sets.

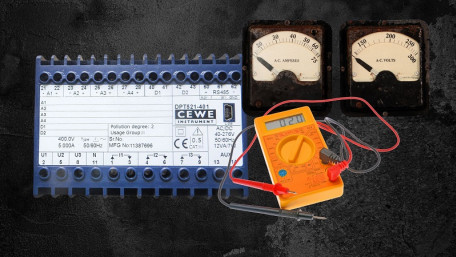

In any process industry, transducers are the basic instrumentation unit for continuous monitoring of system variables…

In any process industry, transducers are the basic instrumentation unit for continuous monitoring of system variables that provide inputs for control system algorithms and outputs.

Learn all about the central processing unit (CPU): the built-in module inside the PLC responsible for executing the…

Learn all about the central processing unit (CPU): the built-in module inside the PLC responsible for executing the program and communicating with external devices.

Building precise rotating or linear systems often costs a lot! When is it justified to spend the extra cost to design and…

Building precise rotating or linear systems often costs a lot! When is it justified to spend the extra cost to design and build such a system, and what are the different components and system types?

Do you know enough about electricity to poke around in a conversation, but not inside a breaker panel? Read on for an…

Do you know enough about electricity to poke around in a conversation, but not inside a breaker panel? Read on for an introduction to electricity in a way you’ve (probably) never heard it before!

Learn how to use Festo’s FluidSIM software to design and simulate electro-pneumatic systems, featuring a reciprocating…

Learn how to use Festo’s FluidSIM software to design and simulate electro-pneumatic systems, featuring a reciprocating actuator example using solenoid valves and limit sensors.

Logic is critical for industrial control, and it usually looks like ladders, function blocks, or structured text. I/O…

Logic is critical for industrial control, and it usually looks like ladders, function blocks, or structured text. I/O controllers are designed to automate simple logic tasks and data functions.

An age-old debate in PLC programming: investigating the uses and caveats of latching software commands versus seal-in…

An age-old debate in PLC programming: investigating the uses and caveats of latching software commands versus seal-in ladder logic for industrial control applications.

It's important to keep your system up and running without regular intervention. While every system requires maintenance,…

It's important to keep your system up and running without regular intervention. While every system requires maintenance, never overlook the critical importance of tools and training for the operators.

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design…

Learn how to connect analog inputs, either voltage or current, to the Phoenix Contact’s IIoT PLC platform and design simple data processing programs with the PLCnext Engineer IDE.

When setting up a system for the first time, the process can seem complex and daunting. However, there are tools…

When setting up a system for the first time, the process can seem complex and daunting. However, there are tools available to make the job much easier before commissioning.

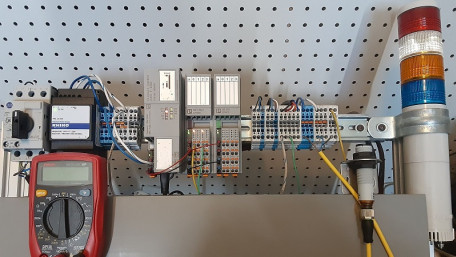

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a…

Learn how to get started with Phoenix Contact’s PLCnext and Engineer software, a platform that ultimately provides a PLC environment for plant control as well as an OS for more advanced IIoT projects.

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic…

Sensor networks with built-in logic functions can save cost and program execution speed, but what are those various logic functions, and when might they be preferred over normal PLC ladder logic?

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary…

Every automated cell requires a ‘brain’ in order to achieve the required tasks. How do you determine the necessary I/O, communication protocols, and processor necessary for controlling your system?

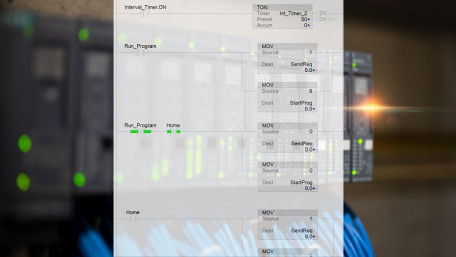

Learn how to write a ladder logic program to assign a string value to a data register and share that register with any…

Learn how to write a ladder logic program to assign a string value to a data register and share that register with any HMI compatible with Mitsubishi’s MELSEC PLC series.