Analog voltage and current are the dominating standards for industrial technology. Is one format better than the other? And if so, why do both signal types still…

Analog voltage and current are the dominating standards for industrial technology. Is one format better than the other? And if so, why do both signal types still exist in modern systems?

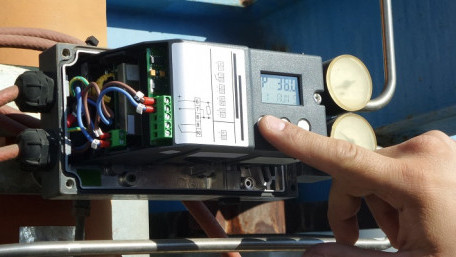

Whether working with measurement tools or process controllers, it is important to recognize faulty display values and the…

Whether working with measurement tools or process controllers, it is important to recognize faulty display values and the best ways to fix them.

Control.com’s Director of Engineering got to explore IO-Link sensors and what he found might surprise you! Although…

Control.com’s Director of Engineering got to explore IO-Link sensors and what he found might surprise you! Although still considered an “emerging” technology, it’s clear IO-Link technology boasts several bonafide benefits over traditional sensors.

From forest to felling, logging road to mill, finished lumber’s adventure on its way to market is filled with control…

From forest to felling, logging road to mill, finished lumber’s adventure on its way to market is filled with control and automation. Learn about the process from start to finish and how lumber mills ensure the world has access to high-quality lumber thanks to control technology.

Triggering a machine by an external event often requires a pulse timer for OpenPLC Pulse Timer control. Here’s a brief…

Triggering a machine by an external event often requires a pulse timer for OpenPLC Pulse Timer control. Here’s a brief tutorial on how an M5Stack Core can offer a simple, effective low-cost Arduino OpenPLC HMI solution.

Many articles address the wiring and implementation of analog control signals, but where are they used, and what might…

Many articles address the wiring and implementation of analog control signals, but where are they used, and what might make them a better (or perhaps worse) decision than digital input/output devices?

Compliance and compensator devices are used in processes where variation and uncertainty are prevalent. What sorts of…

Compliance and compensator devices are used in processes where variation and uncertainty are prevalent. What sorts of compliance devices are used, and what distinct advantages are held by each?

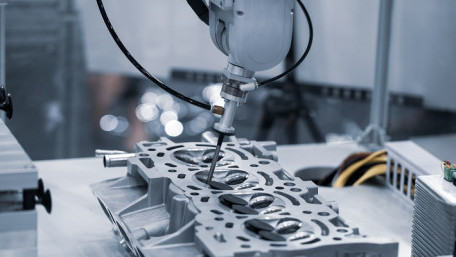

Force compensators and force compliance end effectors can expand the capabilities of traditional robotics to reach into…

Force compensators and force compliance end effectors can expand the capabilities of traditional robotics to reach into difficult processes, ranging from grinding and alignment to precision measurement.

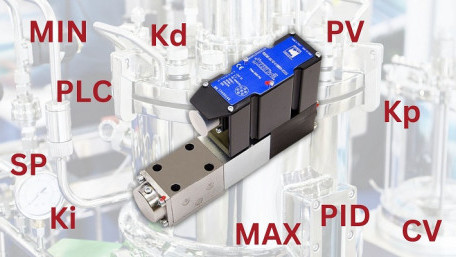

Implementing PID control in a PLC is far more complicated than textbooks would make it appear. There is more to the…

Implementing PID control in a PLC is far more complicated than textbooks would make it appear. There is more to the process than simply picking gain (k) values and calculating an output value.

Direct current (DC) motors have existed since the late 19th century. What sets these motors apart from AC models, how do…

Direct current (DC) motors have existed since the late 19th century. What sets these motors apart from AC models, how do you control them, and how can you tell when it’s time to repair or replace them?

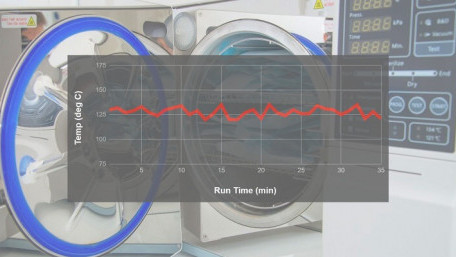

Temperature profiling is an effective tool to monitor thermal properties in process equipment. This article defines…

Temperature profiling is an effective tool to monitor thermal properties in process equipment. This article defines temperature profiling, discusses the process components, and describes the various benefits it offers.

Learn how to build a machine learning model to predict failure classification based on machine parameters using a…

Learn how to build a machine learning model to predict failure classification based on machine parameters using a synthetic dataset modeled after a milling machine, the same process used in real-world systems.

Process automation relies on precise control systems to operate production equipment for everything from lumber to…

Process automation relies on precise control systems to operate production equipment for everything from lumber to pastries. Using control algorithms produces stable, accurate, and often delicious results.

We see smoke detectors on a daily basis in every house and building we visit, but the same sensor elements, and others,…

We see smoke detectors on a daily basis in every house and building we visit, but the same sensor elements, and others, can be used to detect the presence of harmful gasses and heat in all industries.

Designing, installing, and maintaining control systems involves a lot of wires. Each wire has a purpose, often indicated…

Designing, installing, and maintaining control systems involves a lot of wires. Each wire has a purpose, often indicated by the color of the insulation. But what are the common colors, and what do they mean?

Flow sensors measure the flow rate of liquids or gasses in pipes, ducts, and other fluid systems to help monitor and…

Flow sensors measure the flow rate of liquids or gasses in pipes, ducts, and other fluid systems to help monitor and control processes, prevent system failures, and optimize performance.

Level sensors are used to measure the level of a substance, usually a liquid or granular material, in a container.…

Level sensors are used to measure the level of a substance, usually a liquid or granular material, in a container. Different types of level sensors include capacitive, ultrasonic, acoustic, and radar.

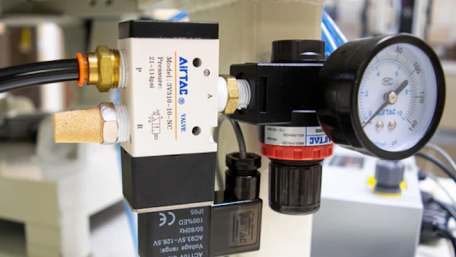

Pressure sensors are essential tools in industrial applications, required wherever there is a hydraulic or pneumatic…

Pressure sensors are essential tools in industrial applications, required wherever there is a hydraulic or pneumatic system to keep pressure quantities under control.

Calibration is performed on a regular basis to ensure proper measurement tool function, but how do we determine the…

Calibration is performed on a regular basis to ensure proper measurement tool function, but how do we determine the proper interval? Factors include environment, usage, and level of dependence on proper function.

Calibration can be a time-consuming process requiring expensive traceable tools, but high-accuracy signals result in…

Calibration can be a time-consuming process requiring expensive traceable tools, but high-accuracy signals result in higher-quality products, better customer satisfaction, and, ultimately, greater returns.