Statistical process control (SPC) allows for continual improvement process (CIP), a method of optimizing a process driven by data and statistical methods.

Statistical process control (SPC) allows for continual improvement process (CIP), a method of optimizing a process driven by data and statistical methods.

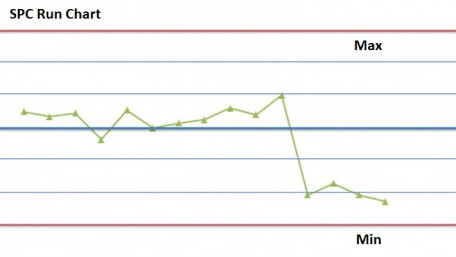

Learn how control charts are used in statistical process control (SPC) to show how a process changes with time as…

Learn how control charts are used in statistical process control (SPC) to show how a process changes with time as compared to past measurements, providing reliable visualizations for data-driven decisions.

Statistical process control (SPC) is meaningless without the proper collection and analysis of data. For some process…

Statistical process control (SPC) is meaningless without the proper collection and analysis of data. For some process parameters, this is a simple task. But not every part of a process is driven by simple, quantitative parameters.

Any industrial electrician can instantly recognize a relay, but when it comes to wiring, why are the terminals numbered…

Any industrial electrician can instantly recognize a relay, but when it comes to wiring, why are the terminals numbered in such apparently random order?

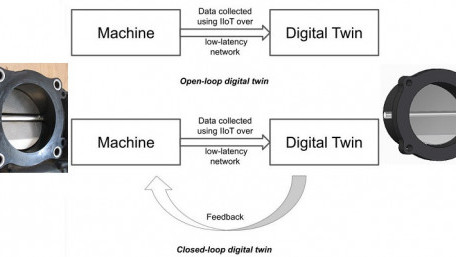

Data feedback loops create a closed-loop digital twin (CLDT) driving increased operational efficiency and improved design…

Data feedback loops create a closed-loop digital twin (CLDT) driving increased operational efficiency and improved design iteration progress.

Learn how statistical process control (SPC) can provide a foundation for decisions used to reduce waste and increase…

Learn how statistical process control (SPC) can provide a foundation for decisions used to reduce waste and increase efficiency in the manufacturing process.

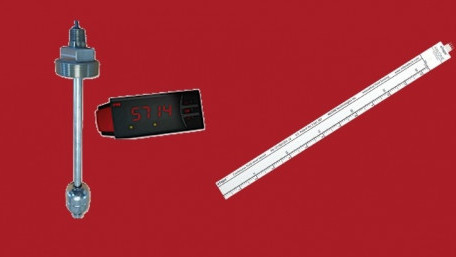

Flow totalizers, flow sensors, and flow meters are popular devices for measuring flow. However, this article discusses…

Flow totalizers, flow sensors, and flow meters are popular devices for measuring flow. However, this article discusses alternative methods, such as ultrasonic level detection and resistive tape.

Learn about obstacles businesses face implementing predictive maintenance and how to overcome them.

Learn about obstacles businesses face implementing predictive maintenance and how to overcome them.

Learn the definition of failure mode and effects analysis (FMEA), steps to execute it, and applications in the industry.

Learn the definition of failure mode and effects analysis (FMEA), steps to execute it, and applications in the industry.

Safety is of utmost importance in the day-to-day operations of any system, especially a system where humans and machines…

Safety is of utmost importance in the day-to-day operations of any system, especially a system where humans and machines work together. Learn all about Safety Instrumented Systems and what it takes to keep workers safe, and the system running smoothly!

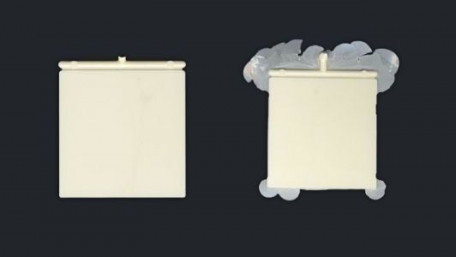

Do you know how the injection molding process works? Learn the basics as well as control processes to consider.

Do you know how the injection molding process works? Learn the basics as well as control processes to consider.

What types of instrumentation are used in wastewater treatment plants? Let’s review the instrumentation and how…

What types of instrumentation are used in wastewater treatment plants? Let’s review the instrumentation and how treatment plants stand out from other industrial facilities.

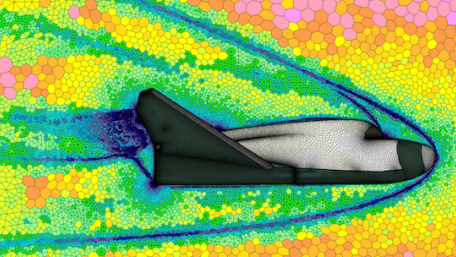

Learn about computational fluid dynamics (CFD) and how it is used in various sectors across the manufacturing industry.

Learn about computational fluid dynamics (CFD) and how it is used in various sectors across the manufacturing industry.

Critical infrastructures like wastewater facilities are largely automated. Let’s dive into the automation systems used…

Critical infrastructures like wastewater facilities are largely automated. Let’s dive into the automation systems used in wastewater facilities.

This article teaches the definitions of big data and data lake, how to use them together, and industrial applications.

This article teaches the definitions of big data and data lake, how to use them together, and industrial applications.

MTTR and MTBF are metrics utilized to determine equipment downtime. How do you calculate these metrics, and how can a…

MTTR and MTBF are metrics utilized to determine equipment downtime. How do you calculate these metrics, and how can a control engineer use them for machine reliability?

This article discusses some trends in digital transformation, specifically matching real-world data with resources and…

This article discusses some trends in digital transformation, specifically matching real-world data with resources and gaining control in an ever-changing world.

Different conveyance systems have different ways to calculate speed. Let’s dive into these systems, their speed, and…

Different conveyance systems have different ways to calculate speed. Let’s dive into these systems, their speed, and some determining factors.

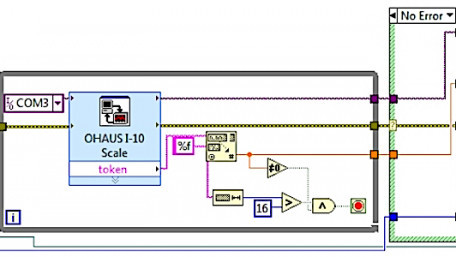

Simple errors may corrupt data files, crash LabVIEW, or crash the entire computer system. Implementing error clusters…

Simple errors may corrupt data files, crash LabVIEW, or crash the entire computer system. Implementing error clusters will help prevent these issues. Learn how to set up error clusters for your VI.

Broken industrial machinery can cause unexpected downtime, production loss, and even injury. Let's look at some of the…

Broken industrial machinery can cause unexpected downtime, production loss, and even injury. Let's look at some of the most common issues and how to properly address them.