Components of the Industrial Internet of Things

Learn about the four IIoT architecture layers: perception, network, processing, and application, and how these layers are necessary to implement IIoT in an industrial setting to benefit varying processes.

See our previous articles covering the IoT and cloud:

Cloud Computing and the Industrial Internet of Things

IoT Software Distribution Models: Cloud Based and On Premises

The Internet of Things (IoT) has brought internet connectivity to many everyday devices. From household appliances to wearables, these objects have found success in their respective markets because of their value proposition, which includes the ability to share data and control devices from anywhere. Industrial IoT devices offer the same advantages as consumer-centric IoT devices.

The Industrial Internet of Things (IIoT) refers to IoT as applied in the industry. IIoT takes field devices that have traditionally been isolated from the outside world and allows them to share data over the internet. Likewise, these field devices can be controlled remotely when applicable.

Figure 1. The IIoT has benefited processes such as predictive maintenance, real-time inventory management, and asset management. Image used courtesy of Canva

When IIoT was first introduced, the idea of reaching floor-level components over the internet was considered disruptive. Today, many businesses continue to have reservations primarily due to security concerns. But, as the technology continues to improve, more and more manufacturing businesses are switching to IIoT.

The industry has also slowly realized the benefits of IIoT, which outweigh the risks. For example, a company that employs IIoT has an increased ability to monitor their machines' Overall Equipment Effectiveness (OEE) and automated systems in real time. This ability is thanks to IIoT devices that can directly send relevant data to a centralized cloud-hosted database. Then, a cloud-hosted application can process this data and produce valuable reports about Key Performance Indicators and other metrics.

Several industrial applications and technologies are now possible thanks to IIoT. For example, some industrial processes benefiting from IIoT include predictive maintenance, real-time inventory management, and asset management.

Let's now review the typical architecture needed to implement IIoT in an industrial setting and some of the most common IIoT devices available today.

IIoT Architecture and Components

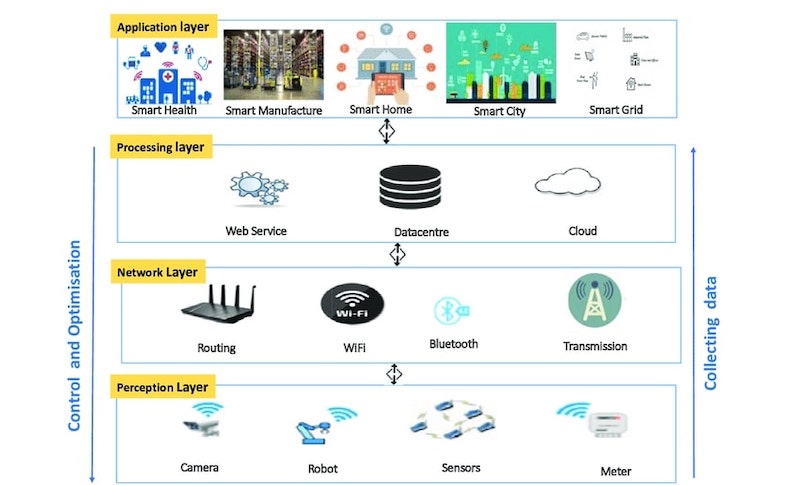

The industry has widely accepted the four-layer model that describes the typical architecture of an IIoT system. The four layers in this model are perception, network, processing, and application, as seen in Figure 2.

Figure 2. The IIoT architecture layers: perception, network, processing, and application. Image used courtesy of Nasr Abosata, Saba Alrubaye, Gokhan Inalhan, and Christos Emmanouilidis

Perception Layer

The perception layer pertains to all the sensors, actuators, devices, and physical objects used to gather data. Therefore, it is also referred to as the edge layer and device layer—a concept that also exists within commercial IoT.

Sensors used in IIoT are called smart sensors. One of the distinguishing characteristics of smart sensors is that they communicate to the network, often via a wireless signal bypassing existing industrial networks which are typically wired. To ensure smart sensors meet the requirements to maintain real-time data transmission reliably, the IEEE developed the 1451.4 standards.

Another important feature of smart sensors is that they are self-identifiable and flexible. The IEEE norm establishes the identification standards, so that smart sensors from multiple vendors can work together and critical sensor information is easily identified.

Controllers for IIoT are also considered part of the perception layer. In IIoT, process controllers are typically embedded and are dedicated to specific functions. So, instead of powerful PLCs that control entire processes, many newer IIoT controlled processes rely on decentralized embedded PLCs. Some consider decentralized control systems to be the predecessors of IIoT controllers.

Figure 4. IIoT Gateways, or Edge Gateways, store and process data locally, such as the above Moxa’s IIoT Edge Gateways with cloud connectivity. Image used courtesy of Moxa

Network Layer

The network layer consists of dedicated IIoT devices that transmit the collected data over the internet. Following the flow of data, starting from the smart sensors and moving up, the next device encountered is an IIoT Gateway.

IIoT Gateways, also known as Edge Gateways, perform the local storing and processing of the collected data before sending it to the next level up in the network. It is important to note that Edge Gateways are not meant for process control and only perform these operations on data before sending it to the cloud. However, they still require high processing power because of the large amounts of processed data.

Some gateways are intended to bring an older process up to more modern IIoT compatibility. These gateways may use a traditional industrial network protocol (RS-485, Modbus, etc) to retrieve information from an existing control system, then convert the data into IIoT-ready packets using standard formats like FTP or MQTT.

Once the Edge Gateway sends the locally processed data, it passes through different network devices before making it to the cloud. The type of devices used here largely depend on the customer preferences and standards, becoming the IT management domain. Also, it is here that security measures are implemented to shield the downstream devices from any outside attacks.

Figure 5. Data reaches a database or server in a data center via the cloud to be processed. Image used courtesy of Canva

Processing Layer

We are now in the cloud domain. At this point, the data has reached a database or server in a data center. Large amounts of computing power are usually needed to execute data analytics and machine learning algorithms. Therefore, the most important data processing occurs in this layer.

In addition to the algorithms, this layer includes web services and all the cloud-based technologies that support the process. A web service describes data transfer from devices to other interfaces and programs.

It is important to note that when data is stored at a remote server location, it is often more secure than local data. When stored locally, the security is entirely the responsibility of on-site IT staff, but when it is managed by a dedicated company, security can be greatly heightened.

Application Layer

In this context, the application layer refers to the graphical user interfaces deployed, which help humans interpret the information that resulted from the previous step. In other words, in this layer, we can find the user programs that generate reports, analyses, and statistics. There are many application layer providers in the market today.

IIoT Solutions

The cloud and IIoT have opened up several industrial applications and technologies not otherwise possible. In our next article, we will take a look at the challenges and best practices of implementing IIoT solutions.

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin