Here’s One for Teachers: How Industry and Education Build Pipelines for the Future

Join Control Automation as we visit Central CA colleges to help install robotic equipment and learn how local industries partner with schools to create exciting opportunities for students.

Each summer, educators at every level, from elementary schools to universities, are given a brief period of time to assess classes and curriculum, polish up equipment, and prepare for new challenges in the upcoming year of work. All of their efforts are designed to help students achieve success.

In many high schools and two-year colleges, various programs align with local industry, usually falling under the workforce or career and technical education (CTE) department. In the world served by Control Automation, we love to learn about robotics, mechatronics, and industrial electromechanical systems. Naturally, anything that falls under the umbrella of “automation.”

But there’s a lot more to education than simply starting a program and hoping for enrollment.

Recently, the Control engineering team was able to visit a couple of colleges between Fresno and Modesto in the central CA valley to support some robotic installations, as well as to learn more about the recipe for developing a relationship between schools and companies, which ultimately builds success for both members of that team.

Figure 1. A material-handling robot in the lab room of the CAM program at Fresno City College

Fresno City College | Robotics in CAM

The college in Fresno offers a specialty in computer-aided manufacturing or CAM. This technology is well-known throughout the industry, enabling much faster time-to-market by providing a seamless transition between the initial digital design phase and the actual fabrication for material removal, addition, and even welding.

But even more recently, robotic integration with CNC manufacturing has continued to accelerate. Under the guidance of instructor Mark McCollough, investments have been made to upgrade the CNC lab with robotic education and machine tending cells to provide students with a foundational knowledge of programming.

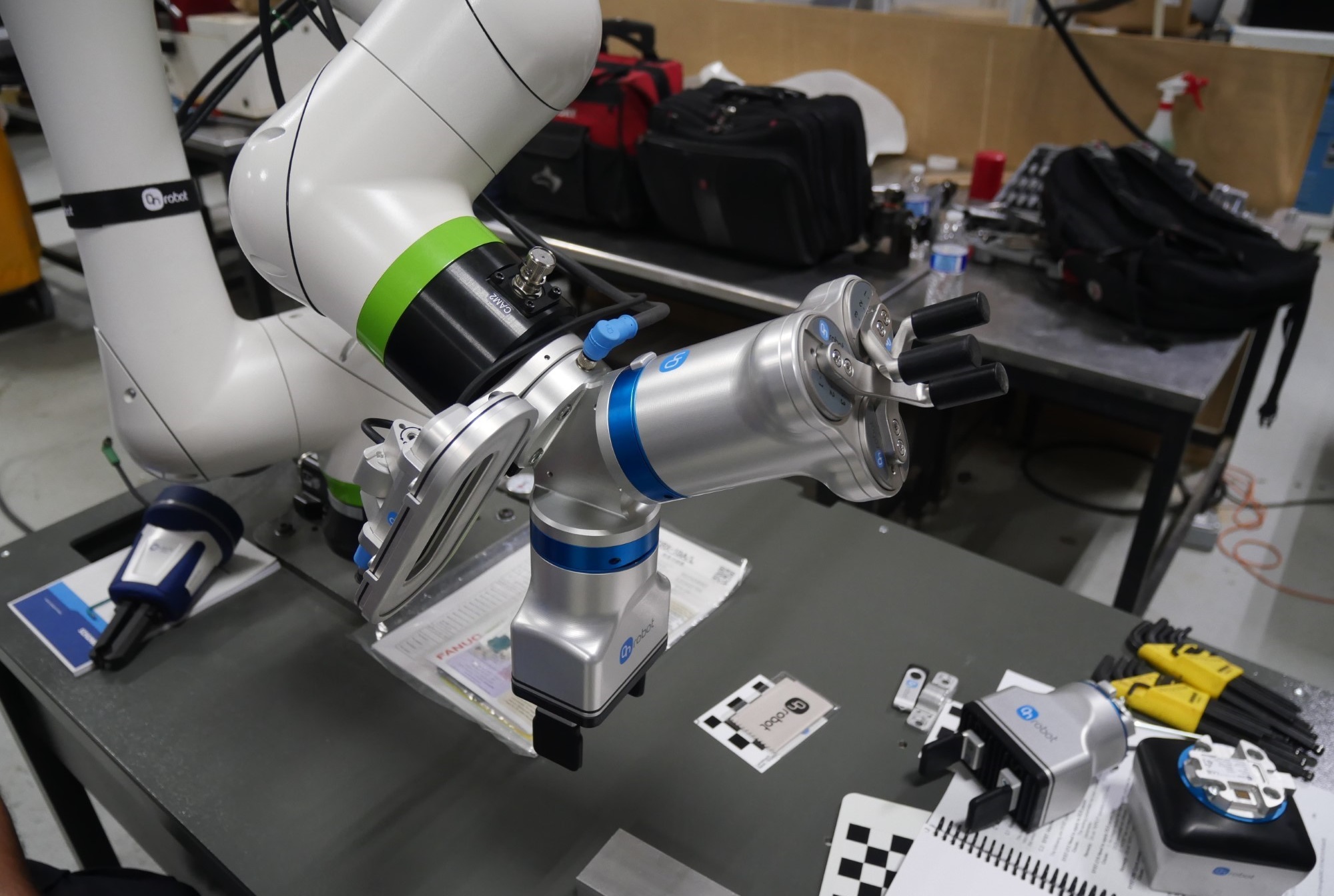

During our visit to the college, we worked together to attach end devices (grippers, vacuums, and vision systems) to the robotic cells and make the necessary software changes to connect the devices via Ethernet. These fundamental technologies are heavily used throughout the industry to connect individual cells to the larger plant network, and now, students will have exposure to these same technologies in the classroom.

Figure 2. Brand-new OnRobot grippers and vision system were attached to a FANUC CRX cobot in the CAM lab room of Fresno City College.

Modesto Junior College | Robotics in Manufacturing Technology

The college in West Modesto received a similar upgrade in facilities in the recent past, moving a fleet of robotic training cells upstairs to a classroom above a machining lab. In the machining lab, several robot-tended CNC machines (FANUC Robodrills) accompany the wide assortment of tools, from manual to automatic, covering a vast array of techniques in the machine tool program, under the careful attention of instructor Eric Silva.

The physical nature of these programs attracts the interest of students and teachers alike, and Silva is no exception. "I love the fact that we are a heavily hands-on learning program. To be able to briefly lecture about a concept and break out into the lab is very helpful. Sometimes we even hold lectures right in the lab as to give the hands-on visuals that some students need to really connect the concepts together."

Figure 3. A FANUC Robodrill used by machining program students in the Modesto Junior College lab.

To understand the full capability of robotic applications in industry, students experience more than machine tending. In the upstairs classroom, students learn on articulated arm (LR series), parallel arm (M1 series), and collaborative (CRX series) robots, each with a different approach to motion and programming.

The installation tasks at this school included similar OnRobot single- and multi-tool grippers but also connections to pneumatic equipment and networked conveyor belts, extending the opportunities for students to engage in bigger project scopes that incorporate multiple work cells and multi-robot handshaking procedures.

It’s important for technology teachers to be well-prepared for classes since the variety of challenges presented by this assortment of technology will never look the same twice. One wrong button on a teach pendant can change the view, add an incorrect command, or change an I/O configuration, and it’s critical to understand how to fix the error.

Figure 4. A few of the robots and conveyors sit in preparation for tooling upgrades at Modesto Junior College.

Industry Partnerships

Educational districts like Fresno and Modesto rely on support from local industry, but what does that look like, and how can a school or company initiate such a partnership if one doesn’t already exist?

For the first question, there isn’t a single answer, and even between these two schools, there are multiple ways in which industry professionals can partner with schools to build the workforce pipeline.

First and most simply, the industry guides schools through advisory committees. These groups consist of representatives from relevant companies, who provide input on which skills and classes are the most necessary. Teachers and administrators compile this input to build the best possible programs that serve the most logical subset of companies in the local vicinity. If you work for a company that doesn’t currently advise a local school, call your nearest high school or college and volunteer to serve.

Silva explains the importance of advisory committee participation for his department in Modesto, "Every year, we hold two advisory meetings with our local industry leaders. We invite them to come onto campus to see our facilities and talk about the changes in industry and at the college we all need to be aware of. During these meetings, we discuss future investments, potential growth opportunities, and methods to better serve the students to be ready for industry."

Providing physical support for the school can include donating funds (which is always possible, but not always feasible for every company), as well as donating equipment. When completing a facility upgrade, before throwing out the old equipment, consider donating that which is truly still useful and effective to the local program. But use discretion. Donating too much or equipment in poor condition can be more of a burden than a benefit; it genuinely helps to have an established relationship with the teachers.

Finally, employment is always on the minds of the students and their teachers. If you have job openings, share these with the instructors. If you are hosting a job fair, share the information with the instructors. If the school is the one hosting the job fair, teachers should be sure to reach out and invite companies.

Figure 5. I got to try out a small video/camera headset used by Modesto instructors for remote teaching and for monitoring and reviewing student work.

What Is the Most Important Step in Building Pipelines?

If one central theme can stand out the most, it is communication.

Engineers: reach out to your local school and learn how you can help, even with the limited time that most of us have at our disposal.

Instructors: call the local companies and learn about their most pressing challenges. Be flexible and open-minded about how your program can meet the needs of your local workforce!

Students: According to Silva, "Don't be afraid to try something different. If something looks interesting or piques your curiosity, don't be afraid to look and inquire further. Many times, I have told my students that we all have a different path when it comes to our education. Don't be afraid to take a class that's a bit outside of your guided pathway. There is more than one road to the finish line, and some may be longer than others, but the important thing is this: never give up."

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin