Motion Control: It’s More Than Just “Point A to Point B”

Building precise rotating or linear systems often costs a lot! When is it justified to spend the extra cost to design and build such a system, and what are the different components and system types?

Let’s set the stage: I have two motors sitting on a bench in front of me.

Both motors are 1 HP. One costs me $223.00, and the other is $510.00. Similarly, one is controlled by a $42.00 on/off magnetic contactor, while the other requires a $600.00 digital controller. One motor gives me rotational movement when I put power to it… But the other gives me motion control.

You might have already guessed that the basic on/off motor is the cheaper one. If you did, you’d be right!

But why should I spend 4-6 times as much money on a motor that gives me the same amount of rotational horsepower?

Why Care About Movement vs. Motion?

Rather than provide a simple blanket statement as an answer to the previous question, I believe it would be best to demonstrate the reason.

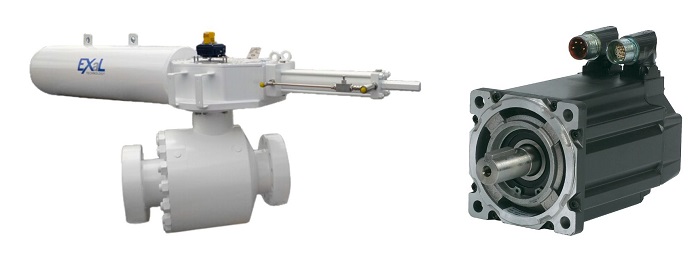

Figure 1. Motion can be in the form of hydraulic or electric, and it can be rotating or linear.

You’re probably reading this article on a computer, so you have a mouse close at hand. Try pushing that mouse exactly 2.354 inches forward. You immediately realize that this is a ridiculous request. Just giving a gentle push and hoping that it lands perfectly in an assigned spot is preposterous. You would need so many things that your hand doesn’t have: exact force control, feedback, tuning, anticipated rates of change, knowledge of how much the mouse weighs, the friction of your mouse pad or table... All that sensing sounds expensive…

I work in the sawmill industry where my job is programming equipment that accomplishes tasks such as log processing, board trimming, and bundle stacking. Some of these systems require us to position an 800 lb log and two 10,000 lb saw systems with up to 4/1000ths of an inch of accuracy.

This is only possible by the use of what we call “motion control.”

Motion Control: Hardware Components

As most industrial personnel know, a standard electric motor spins up when voltage is applied and then spins down to a stop when voltage is removed. Some may have brakes of different types, but the principle is generally the same.

Figure 2. Examples of various servo motor control systems.

A ‘motion control’ system involves many pieces working together. The basic components of an electric motion system include a motor that performs the actual work, an encoder that provides feedback (this combo is usually called a servo), a motion controller that calculates the required voltages to move the system properly, and generally another control system like a PLC that coordinates the entire system.

Hydraulics are widely used in motion control systems as they can provide huge amounts of direct, linear energy instead of the rotational energy of a servo motor. A hydraulic system also requires a number of important components: a hydraulic power unit (usually abbreviated HPU) provides the fluid flow to a proportional control valve that can quickly and precisely control the flow of hydraulic fluid, a linear transducer that gives linear feedback from the cylinder (actuator) instead of an encoder which provides rotational feedback, and, as before, the controller for calculating exact position and coordinating the associated system.

Fine-Tuning a Motion Control System

More than likely, you’ve heard of something called “PID.” This acronym stands for proportional, integral, and derivative gains, the characteristics that allow the system to respond properly. While the list of individual parameters we use in advanced motion control can be over 100 entries long, we are only covering the surface level to give perspective.

PID tuning changes how a system responds. Think about how much energy you need to move a 2 ounce weight a distance of 3 inches. Now, move a 2 pound weight over 3 inches. Finally, move the original 2 ounce weight 3 feet. Each of these movements requires entirely different calculations for motion.

In the hardware section above, we discussed how a motion controller is required to make motion moves. These controllers have the ability to perform calculus functions much more efficiently than a basic control system like your standard PLC. This advanced math is used to calculate different segments of movement that the machine will require.

Don’t worry, we won’t be doing a math class in this article, just some discussion to give you perspective. The acceleration, velocity, deceleration, and rate of change in acceleration or deceleration are all different functions and must be calculated. The PID tuning gives the controller knowledge about how it needs to react to different movements. A higher proportional gain (kP) makes a system respond with much more power sooner. Maybe this is needed for moving a heavy load, but could cause major problems with a light load. The tuning is very important to the overall function of a motion system.

Figure 3. A motion control system with configurable I/O and output axis control for electric or hydraulic motion. Image used courtesy of Delta Motion

Various Manufacturers and Motion Programming

While motion control may be a specialized field, there is a wide variety of manufacturers ready and willing to fill the needs of any application. Delta Motion, Rockwell, Yaskawa, Mitsubishi, SureServo, and so many more! It is also very common for different manufacturers to mix and match their components. Don’t be worried if you come across a system using, for example, a Delta Motion motion RMC controller, a Rockwell PLC, a Temposonic linear transducer, a Cunningham cylinder, and a Rexroth valve. I have seen countless mixed systems like this that operate perfectly, even under extreme conditions.

As there are various manufacturers, you will also find that there is a different programming software (IDE) for each one. Programming a Rockwell system will be completely different from programming a Mitsubishi system. Some manufacturers produce combined motion controllers that can also control the entire system. Rockwell Automation has a lineup of PLCs like this that can control the overarching system and have motion axes integrated into them for their Kinetix Servo systems.

Sometimes it might be necessary to combine multiple systems because a manufacturer that you already use does not support the style of motion system you need. Such is the case for Rockwell’s partner company Delta Motion. When Rockwell legacied its hydraulic motion cards, they began working more closely with Delta Motion to let Delta provide the hydraulic motion in a way that works seamlessly with Rockwell PLCs.

Motion Control System Summary

With the information you have now, you are ready to begin your foray into motion control. We know motion is expensive, complex to build, and complex to program. Regardless of the cost and complexity, countless systems use these systems under the extreme stress of industry.

From an economy model all the way up to a Rolls Royce of hardware, this article series will help equip you with the experience and guidance you need to begin implementing your own motion control systems!

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin