Touching on Touchscreens | Capacitive vs. Resistive Technologies

Two primary technologies are used for creating touchscreens. For industrial HMIs, resistive and capacitive methods both contain certain advantages for various applications.

Touchscreens are everywhere: from smartphones to tablets, to automatic teller machines (ATMs) to industrial control equipment. In terms of human-machine interfaces (HMIs), a well-designed visual UI can be more intuitive to use than virtually any other system in existence. The user can simply press the screen to select the items or controls they need. Touchscreens are also more accessible, as they are easier to use than a keyboard and mouse for people with severe hand trauma or arthritis.

Resistive vs. Capacitive Touchscreens

Currently, there are two competing technologies in touchscreen design. Resistive and capacitive touchscreens each have their advantages and disadvantages, meant to be deployed in different operating circumstances.

Which Screen Has The Right Touch?

Ultimately, the choice of touchscreen type depends on the application. Keep in mind that the unique pros and cons of each type of touchscreen are slowly merging together, making the choice between one or the other harder to distinguish, falling primarily to the current availability for purchase.

Resistive Touchscreens

The older of the two technologies, resistive touchscreens consist of a sandwich structure. The two outer slices are conductive, but have a known resistance. In between the two layers is a gap, filled with air or some dielectric substance. When the screen is pressed, the material between the layers moves out of the way and allows the resistive layers to contact. Based on the detected resistance along both an x and y axis, the sensor knows where the screen has been contacted.

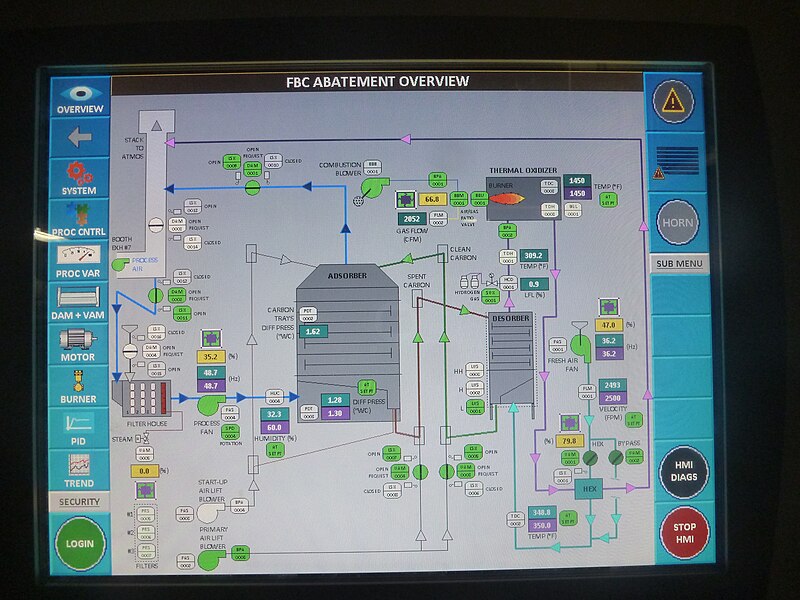

Figure 1. This touchscreen is used in a chemical plant. With so many unit operations, each with different parameters, it is likely a resistive touchscreen operated with a stylus. Image used courtesy of Wikipedia

In general, resistive touchscreens are cheaper to produce and can be activated with bare fingers, a stylus, gloved hands, or various other means. They require more pressure to operate, but do not require a conductive device to press the screen. Their simplistic nature makes them a good choice when simple button presses are required, such as on ATMs, gas pumps and in most ruggedized industrial equipment.

Because they must flex to allow the distortion of the conductive plate, resistive screens tend to be easier to scratch and damage. More than one gas pump screen has been vandalized with a key, as the screen material cuts and crazes easily. Also, complex actions that require multiple touch points, slides, or precise location, such as zooming in or selecting items from several sub-menus become difficult with resistive touchscreens.

Figure 2. Judging from the surroundings, this ATM’s screen is likely vandalized. This is why there are standard buttons on the sides to make it possible to use the ATM even after the screen has been damaged. Image used courtesy of Pexels

Capacitive Touchscreens

Another method of constructing touchscreens uses changing electric fields to register a touch. In these capacitive touchscreens, a glass layer is coated with a transparent conductor. When the screen is touched by a conductor like an ungloved human finger, the electric field changes. This is because the human body essentially acts like the other side of a capacitor. From physics class, remember a capacitor is simply two conductors sandwiching a dielectric. At rest, there is only one conductor and the glass layer, but when contact is made, the capacitor is complete and a charge transfer is detected.

The most common uses for these screens are consumer electronic devices, such as laptops, smartphones and tablets, car infotainment centers, as well as some of the more protected industrial control systems and displays. The outermost layer is glass (often tempered glass for added toughness), and is not expected to flex, unlike the resistive touchscreens. This makes the whole touchscreen more durable, and less likely to scratch or break as compared to the resistive touchscreens.

Capacitive touchscreens tend to be more expensive, but can interpret multiple touch points. This makes it possible to pinch or spread, such as zooming on a map, opening different menus, and other actions that have become widespread thanks to smartphone usage. Complex actions allow for more versatility in the software behind the HMI, making it possible to have more options and more commands, and thus more actions that can be performed by the user.

Figure 3. This smartphone has a capacitive touchscreen. Image used courtesy of Pexels

The sensitivity of the capacitive touchscreen can actually be a limitation in certain situations, as even a slight brush against it can activate the wrong part of the screen. Raindrops, dripping sweat, blowing dust and other contaminants can cause false reading as well. While a raindrop may trigger a response, a gloved hand or stylus may not, as neither of these are conductive and do not change the electric field on the screen.

In a chemical plant, biological laboratory, or other sensitive areas, a capacitive touchscreen might be a safety advantage. Operators are expected to wear nitrile gloves when they are near chemicals. Good industrial hygiene practices mandate glove changes or glove removal when the operator touches surfaces not likely to be contaminated with chemicals, such as door knobs, drawers, cabinets, and touchscreens. Therefore, placing a capacitive screen in these areas will force operators to remove their gloves.

Effective Touch Inputs for Control Systems

Touchscreens will continue to be an important part of industrial control just as much as in everyday consumer life. Their ease of use and accessibility will drive this market forward, allowing users to make intuitive motions to make control decisions. Over the next decade, the disadvantages of both techniques will begin to fade away, and, outside of the physical construction, the usefulness of each type will improve.

Featured image used courtesy of Adobe Stock

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin