Troubleshooting and Testing Single Phase AC Motors

Single-phase motors are common in household and small industrial devices. They are a bit more complex than 3-phase models, so it’s important to recognize failure modes and common symptoms.

Single phase alternating current (AC) motors are commonly used in household appliances and other simple industrial applications. Everything from the compressor on the refrigerator to the water pump, to the ceiling fan in a standard house uses a single phase AC motor. These motors are commonly used in applications where the motor either has two states (on and off) or can be run at a constant speed, potentially selected from several possibilities.

Single Phase AC Motors

A single phase AC motor consists of several important parts. Most of these motors contain two coils of wire: a start winding and a run winding, though these are sometimes called the main winding and the auxiliary winding, respectively. The windings comprise the stator, the non-moving outer part of the motor which generates a magnetic field influencing the rotation of the shaft which is appropriately called the rotor.

Many single phase motors have a startup capacitor, which both supplies extra inrush current for starting the motor, but mainly causes a slight shift in the timing of the maximum current. If there is one, it will be wired in series with the start winding so that the timing of the max current (and following magnetic field) will produce a consistent starting direction.

Single phase motors may also have multiple taps, meaning multiple places to apply current to the coils. This serves as the motor’s speed control. Think of a box fan; fans may have three speed settings and an OFF position. Those three speed settings are often three separate taps, with the highest speed coming from the tap with the fewest windings and least impedance. This process only works when the load on the motor is very small.

Are you a motor troubleshooting expert? Quiz yourself with our (no pressure) worksheet!

Figure 1. This fan has a single phase AC motor at its core, and it can run at several different speeds. Image used courtesy of Adobe Stock

Testing a Single Phase AC Motor

There are four common failure modes for single phase AC motors. First, one of the windings can break, leading to an open circuit. Second, the insulation can fail, leading to a short circuit. Third, the motor can be overloaded for numerous reasons (which can also lead to the first failure). The fourth failure mode is the failure of the starting capacitor, if the motor is equipped with one.

Broken Windings - Open Circuit

One of the most common reasons for motor failure is broken windings. In this failure mode, the wire in one of the two windings has severed, and the magnetic field is not being generated. The obvious symptom of a broken winding is that the motor does not turn when powered, but it may spin freely when turned by hand.

Often, the failure is at one of the connection points, but the windings can fail anywhere. Unfortunately, if the winding is broken in the middle, it can be hard to find and is rarely worth repairing, as the motor will need to be rewound. If the winding is broken at one of the terminals, this can typically be repaired.

Testing for a broken winding is notoriously difficult on single phase motors. Since the start winding contains a capacitor and has a different impedance, it is impractical to measure each winding to locate the fault.

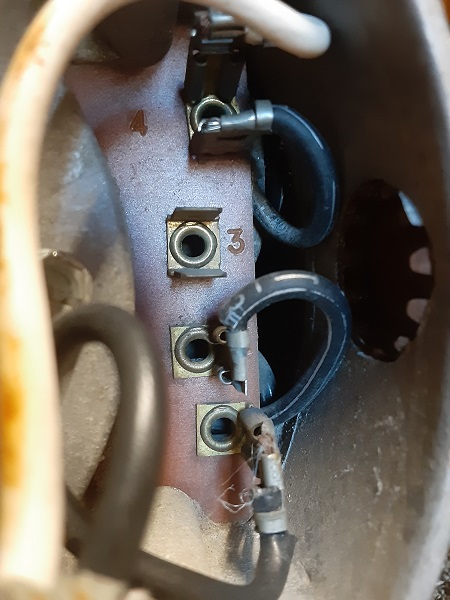

Figure 2. The inside of a single-phase motor has access to the start, run, and common terminals, but what is the order? Test at the main supply leads instead.

All single phase motors will have two wires entering the casing, L and N. Often, there’s a third ground wire as well. Place a multimeter across the L and N leads and set the meter to resistance. The value should start at a lower resistance, but not zero, and should quickly increase a bit and level off at a slightly higher value (this is intentionally vague, as the exact resistance values depend on the motor size).

This action indicates that the capacitive start winding was indeed being charged properly and is functional, and since the resistance reached a steady level, this also indicates that the run winding is functional. If the start winding is open, the resistance will not change at all. If the run winding is open, the capacitor will keep charging and the resistance will slowly keep increasing.

Insulation Failure - Short Circuit

The opposite of a broken winding is a short circuit where the insulation has failed. This might be found through visual inspection where worn, melted, or otherwise damaged insulation in the coil windings. However, sometimes the damage is hidden inside the casing, or invisible to the human eye, as certain chemical exposure or thermal degradation of insulation can lead to the change in dielectric properties of the wire insulation, which must be determined using other means.

The first test for determining insulation failure is to use a multimeter to see if there is continuity or low resistance between the S terminal and the housing or chassis. This test is then repeated with the R terminal. Finally, the C terminal and the housing should be tested. In spite of common language (common, grounded, etc), there should be high resistance between the C terminal and the motor chassis. If any of these tests indicate a low resistance, the insulation may be damaged.

Another test is to use a megohmmeter to test the insulation, in case the resistance value is lower than it should be, but not completely zero like a true short-circuit.

A megohmmeter places high voltage across its terminals so that very high resistances can be measured. Even if a motor has passed the multimeter test, it is still a good idea to test with a megohmmeter. Readings below a megaohm indicate either a direct short or an insulation or dielectric breakdown. Extra caution must be used when testing with a megohmmeter, as they can be used to apply 5000 V or more.

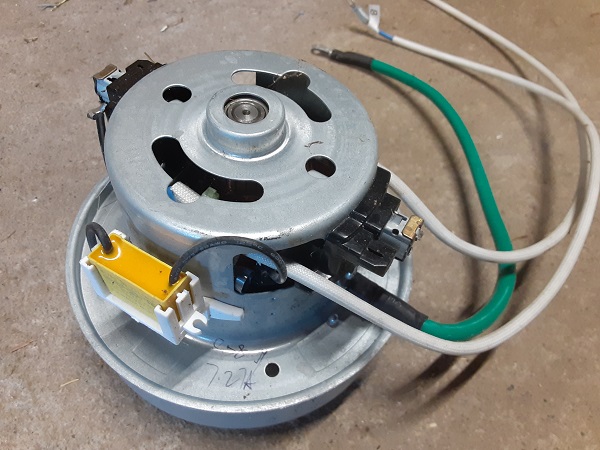

Figure 3. This motor is a commutating AC motor that applies current to windings in the rotor as well as the stator.

Motor Overload

I (the author) first experienced single phase AC motor overload when he was a kid. From the top bunk of his bunk bed, he kept piling clothes on the ceiling fan and turning it on. It seemed like a fun game, for a while. Eventually, a pair of pajama pants got wrapped around the fan, and combined with the load of the other clothes and the imbalanced nature of the stacking, the fan stopped spinning, humming lightly instead. Suddenly the lights went out in the room. The motor kept drawing more current until the breaker tripped.

Lots of conditions can lead to motor overload, such as physically overloading the motor, as described above, not performing maintenance, so that lubricated surfaces become unlubricated, collecting dust and debris that can stall the motor, and other such situations. Furthermore, many of these motors also have a thermal switch that can open if the motor is running too hot. This is sometimes a problem with home appliances when their vents are blocked on crowded countertops or shoved into a corner for aesthetic rather than functional purposes.

Overloading can be fixed by examining the motor and its operating conditions, and then changing them. Replacing a set of worn bearings, removing some of the load, applying grease, or moving the motor to a location with better ventilation can fix this problem. However, it might be worth checking the windings if the motor has been overloaded multiple times to ensure that the insulation has not been thermally damaged.

Capacitor Failure

Some motors have a large capacitor for boosting and shifting the current to start the motor. This startup capacitor is only engaged, charging and discharging during startup. If a motor is equipped with a startup capacitor and intermittently or permanently fails to start, yet the motor turns freely, and no breakers are being flipped, it is possible the startup capacitor is bad.

Capacitors that have failed may be physically damaged. Any capacitor that is bulged at the sides or has leaked electrolyte should be replaced. However, some simply dry out, and there are no visible clues to their failure. A good multimeter can be used to check the startup capacitor. Take caution, however, when handling capacitors. If a capacitor is working, it may retain a charge for years after being disconnected from the power.

Figure 4. This old motor on an air compressor has a large capacitor for the start winding.

Single Phase AC Motors

Single phase AC motors are very common in the household and for small appliances. While they do not operate as smoothly, have limited control options, and tend to wear out faster than their three phase counterparts, their simplicity and inexpensive construction make them a popular choice for consumer goods.

While troubleshooting of these motors is possible, it is often cheaper to replace the motor or maybe even the entire device, than it is to repair the motor.

Interested in more content about motors? We have plenty to choose from!

Articles:

- Comparing Single-Phase and Three-Phase Motors

- 3-phase Motor Types: Synchronous and Induction Motors

- Understanding Delta Wound Motors for Industrial Applications

- Brushed vs. Brushless DC Motors

- Field-oriented Control (Vector Control) for Brushless DC Motors

- Teardown: What’s Inside a 3-Phase Induction Motor?

Textbook:

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin

“Great article! Troubleshooting and testing single-phase AC motors can be a complex task, but your explanation of the common failure modes and symptoms is really helpful. It’s interesting to learn about the different parts of a single-phase motor and how they work together. Your insights on broken windings, insulation failure, motor overload, and capacitor failure provide valuable information for diagnosing motor issues. Thanks for sharing your expertise!”