Electricity and Electronics

Troubleshooting Electrical Motors

-

Question 1

In a motor control circuit, the ‘start’ button is pressed, and the motor fails to turn on.

What might be some possible failures? Describe a simple test that could diagnose each option.

Reveal answerExample failure possibilities:

The contactor/starter is not working.

- Check the voltage of the coil and contact terminals to ensure proper function.One or more motor coils are open.

- Check the coils with an ohmmeter if disconnected. The resistance between all T leads should be the same. Check the coil voltage if energized. The voltage between all T-leads should equal the supply voltage.Motor load is too heavy.

- Check motor OL relay, if tripped, the load might be too much for the motor.The start circuit has failed.

- Verify that the contactor/starter coil receives voltage at the right time (when it should be energized). -

Question 2

After years of dedicated service, a medium sized 3-phase motor stops running with the obvious smell of burned electronics and smoke.

Obviously, the motor has overheated, so you lock out the motor and grab a multimeter to diagnose the problem.

What would be the most logical measurements to obtain first, and what do they mean?

Reveal answerMeasure the resistance between the 3x T-lead connections with the motor disconnected.

There are three measurements to be made T1-T2, T1-T3, and T2-T3. All measurements should be nearly equal. If a discrepancy is found in any winding, the motor must be repaired or replaced.

-

Question 3

When measuring motor winding resistance, explain why a measurement of very high or very low might both indicate motor failure.

Reveal answerLow resistance (that is to say, lower than the other winding sets) would likely indicate overcurrent through that winding resulting in melted coil insulation and shorted windings.

If this motor is allowed to run further, that entire winding set will overheat further due to increased current.

If the motor winding is too high (again, higher than the other windings), this could indicate two things:

First, there may be a failure in the remaining two windings, causing their respective resistances to decrease, and further overheat.

If the resistance is very high, the winding has likely burned entirely and become ‘open’ in which no current will flow through that winding and the motor will be imbalanced or not run at all.

-

Question 4

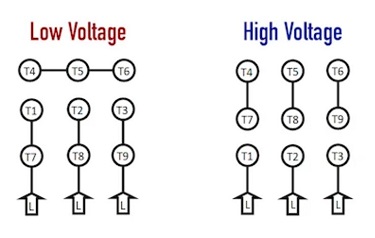

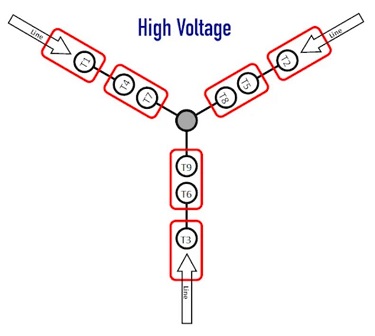

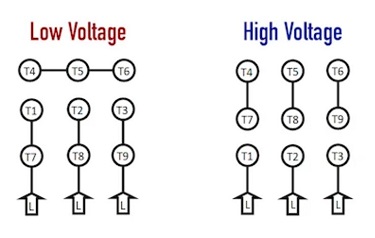

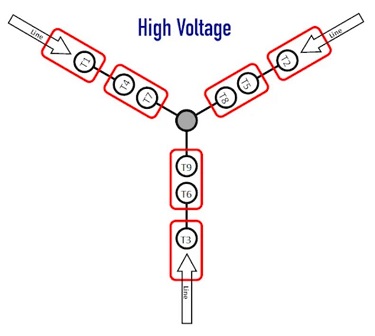

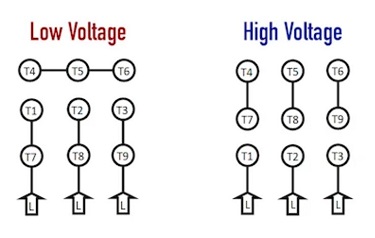

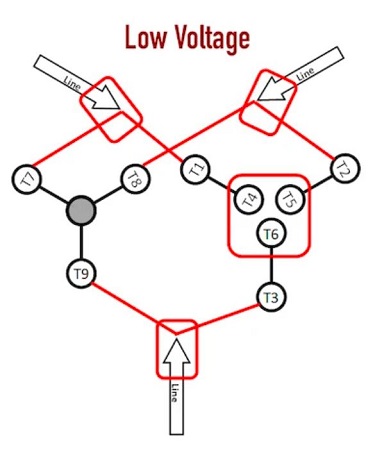

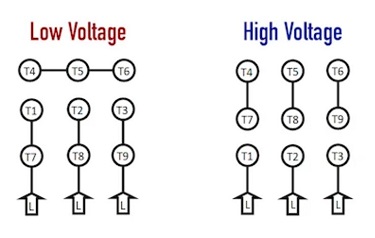

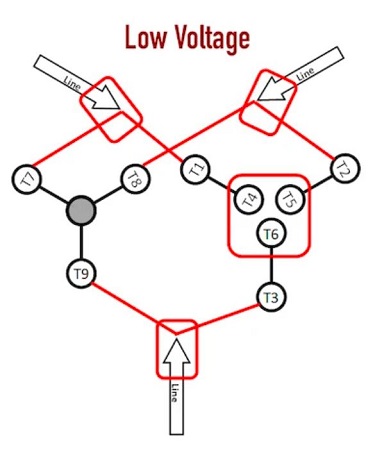

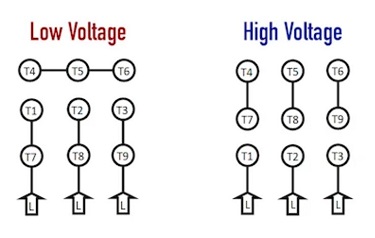

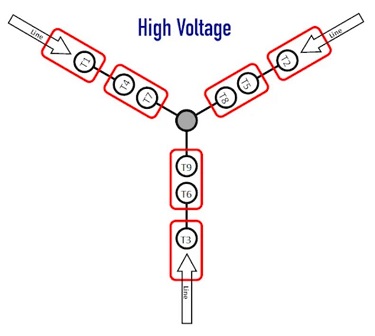

You are troubleshooting a faulty motor. This is a typical 9-wire 3-phase motor configured for 480 volts.

Resistance measurement from T1-T2 measures 8 Ohms.

Resistance measurement from T2-T3 measures 6 Ohms.

Resistance measurement from T1-T3 measures 6 Ohms.What is the fault in this motor?

Reveal answer

The fault is a shorted coil, either T9-center or T6-T3.

-

Question 5

You are troubleshooting a faulty motor. This is a typical 9-wire 3-phase motor configured for 480 volts.

Resistance measurement from T1-T2 measures OL.

Resistance measurement from T2-T3 measures OL.

Resistance measurement from T1-T3 measures 8 Ohms.What is the fault in this motor?

Reveal answer

The fault is an open coil, either T8-center or T5-T2.

-

Question 6

You are troubleshooting a faulty motor. This is a typical 9-wire 3-phase motor configured for 208/230 volts.

Resistance measurement from T1-T2 measures 2 Ohms.

Resistance measurement from T2-T3 measures 4 Ohms.

Resistance measurement from T1-T3 measures 4 Ohms.What is the fault in this motor?

Reveal answer

The fault is an open coil, either T9-center or T6-T3.

-

Question 7

You are troubleshooting a faulty motor. This is a typical 9-wire 3-phase motor configured for 208/230 volts.

Resistance measurement from T1-T2 measures 1.66 Ohms.

Resistance measurement from T2-T3 measures 2 Ohms.

Resistance measurement from T1-T3 measures 1.66 Ohms.What is the fault in this motor?

Reveal answer

The fault is a shorted coil, either T7-center or T4-T1.

-

Question 8

You are troubleshooting a faulty motor. This is a typical 9-wire 3-phase motor configured for 480 volts.

Resistance measurement from T1-T2 measures 4 Ohms.

Resistance measurement from T2-T3 measures 8 Ohms.

Resistance measurement from T1-T3 measures 4 Ohms.What is the fault in this motor?

Reveal answer

The fault is both coils shorted, T7-center AND T4-T1.

-

Question 9

A problem motor circuit appears to trip a ground fuse protection circuit occasionally.

What is the proper tool and method to identify the possible problem?

Reveal answerA mega-ohmmeter (or ‘megger’) should be used to test the insulation resistance between all T leads and the ground wire or case of the motor.

-

Question 10

Using a standard multimeter, you check the resistance between T1-ground (outside metal case of the motor).

You measure 1.2 Megaohms of resistance.

What is your analysis? Does this measurement indicate a problem?

Reveal answerWhile 1.2 megaohms at 480 volts does not signify a problem current according to Ohm’s Law (I = V/R, so 0.4 mA), this is a smaller resistance than should be measured for a motor insulation value.

In general, if the resistance falls near or below 1 MOhm, the insulation is failing and the motor should be serviced or replaced.

During operation, factors such as rotor position, heat, and vibration might affect the resistance, and it may periodically reduce, increasing current and triggering a ground current fault if monitored (like a ground fault relay).

Facebook

Facebook Google

Google GitHub

GitHub Linkedin

Linkedin